- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

0.02 T

-

Power (kW):

-

10

-

Power:

-

10kw

-

Inverter:

-

igbt

-

Power factor:

-

>95%

-

Duty cycle:

-

100%

-

Crucible Material:

-

pure graphite

-

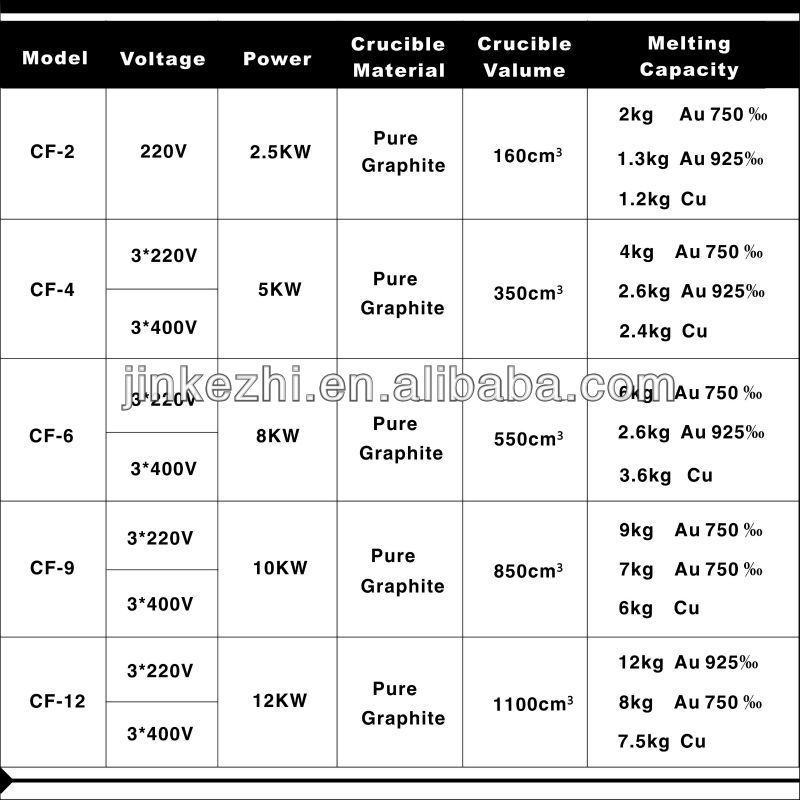

Crucible Volume:

-

850c㎡

-

Application:

-

gold melting

-

Origen:

-

Chengdu, Sichuan, China

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

JKZ

-

Voltage:

-

3 phase 220v, AC220V 50-60hz or customized

-

Weight (T):

-

0.02 T

-

Power (kW):

-

10

-

Power:

-

10kw

-

Inverter:

-

igbt

-

Power factor:

-

>95%

-

Duty cycle:

-

100%

-

Crucible Material:

-

pure graphite

-

Crucible Volume:

-

850c㎡

-

Application:

-

gold melting

-

Origen:

-

Chengdu, Sichuan, China

Gold melting furnace induction heating machine

Application Range:

Non-ferrous and ferrous metals melting

Precious metal melting, like gold, sliver, platinum,etc.

Semiconductor material melting

Specialized steel, iron, copper melting

Metal alloy melting, like aluminum alloy, zinc alloy, copper alloy,etc.

Other metal melting applications

induction melting furnace for gold

MOSFET (SIEMENS) technology, high conversion efficiency; Energy saving 15%-30% , compared to SCR/KGPStechnology

Much more efficient than gas-fired and coal-fired method

100% start-up success rate; power factor > 95%

Perfect and complete protection functions, increasing machine's reliability & stability

No special foundations required, Low operating cost, Easy operation

Modular design, ease of maintaining and repairing

Gold Induction Melting Furnace

Advantages:

Energy saving, Environmental protection, Low pollution level

Easy operation, can be equipment with PLC controller

Miniature and light weight, Economic Space Occupation, Easy installation

Enhanced monitoring and diagnostics system—"JKZ-PS" device, guarantee the machine of high stability, reliability and security.

Strict Supplier Management System and ISO9001-2008 Quality Management System guarantee high quality of each equipment.

Customized services, producing machines according to customer's requirement.

Precious metal melting, like gold, sliver, platinum,etc.

Semiconductor material melting

Specialized steel, iron, copper melting

Metal alloy melting, like aluminum alloy, zinc alloy, copper alloy,etc.

Other metal melting applications

induction melting furnace for gold

MOSFET (SIEMENS) technology, high conversion efficiency; Energy saving 15%-30% , compared to SCR/KGPStechnology

Much more efficient than gas-fired and coal-fired method

100% start-up success rate; power factor > 95%

Perfect and complete protection functions, increasing machine's reliability & stability

No special foundations required, Low operating cost, Easy operation

Modular design, ease of maintaining and repairing

Gold Induction Melting Furnace Advantages:

Energy saving, Environmental protection, Low pollution level

Easy operation, can be equipment with PLC controller

Miniature and light weight, Economic Space Occupation, Easy installation

Enhanced monitoring and diagnostics system—"JKZ-PS" device, guarantee the machine of high stability, reliability and security.

Strict Supplier Management System and ISO9001-2008 Quality Management System guarantee high quality of each equipment.

Customized services, producing machines according to customer's requirement.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Professional R & D team And designing team, famous technical experts of rich induction heating knowledge, Every product own intellectual property right. These make us the one of leader of advanced induction heating technology in China.

|

Packaging

|

|

|

|

Size

|

660*300*500mm

|

|

|

Weight

|

20kgs

|

|

|

Packaging Details

|

induction pipe heater packing material is plywood box, suitable for export.

|

|

FAQ

Q1, what is your application?

For example: induction brazing/ billets forging heating/ heat treatment/ melting furnace

Q2, what is the workpiece metal material/ dimention?

Forexample:steel/stainless steel/brass/copper/Aluminum,etc

diameter, length, thickness, heating zone length, heat treatment layer depth

Q3, What is the request heating temperature and time?

For example: heating temperature 1000C, 500kgs/hour

Q4, Does your company work on OEM?

Yes, we have a professional design and technical team to do the customization

Q5, What’s the delivery time after the order is placed?

We arrange the shipment in 3-15 days for standard machine. It takes us more days for customized machines

Q6, How about the warranty?

The warranty is one year by offering spare parts for free and we provide lifelong maintenance.

Q7, What can you provide after service?

We provide machine running video, instruction manual in English, spare parts Also

our engineers are available to clients’ factory and technical training.