- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shunfu

-

Voltage:

-

220V/380V

-

Power:

-

90kw

-

Dimension(L*W*H):

-

depended on machine configuration

-

Weight:

-

5000 kg

-

Marketing Type:

-

2021 hot product

-

Product Name:

-

Paperboard Machine

-

Raw material:

-

Waste paper, waste paper pulp, paper sludge etc

-

Thick of paper:

-

can debugging

-

Output paper style:

-

paperboard sheet

-

Capacity:

-

as per your requests

-

Speed:

-

High speed full automatic

-

Dryer:

-

Hot pressure dryer

-

Cutter:

-

Automatic cutter

-

After Warranty Service:

-

Online support, Free spare parts,Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Production Capacity:

-

20sets/month

-

Product Type:

-

Paperboard Machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunfu

-

Voltage:

-

220V/380V

-

Power:

-

90kw

-

Dimension(L*W*H):

-

depended on machine configuration

-

Weight:

-

5000 kg

-

Marketing Type:

-

2021 hot product

-

Product Name:

-

Paperboard Machine

-

Raw material:

-

Waste paper, waste paper pulp, paper sludge etc

-

Thick of paper:

-

can debugging

-

Output paper style:

-

paperboard sheet

-

Capacity:

-

as per your requests

-

Speed:

-

High speed full automatic

-

Dryer:

-

Hot pressure dryer

-

Cutter:

-

Automatic cutter

-

After Warranty Service:

-

Online support, Free spare parts,Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

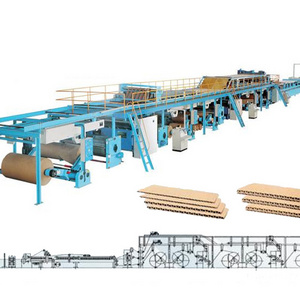

Fully automatic high speed corrugated cardboard production line plant waste carton cardboard recycling machine

Sludge Paperboard Making Machine

The board thickness is large because it is a multilayer combination, so the board machine is made from the same type of the same or different types of forming device, and equipped with multi-channel pre press and multi-channel main press. Thin board a multi cylinder contact drying, the cardboard is often equipped with other drying device. The pressure of light after finishing the cardboard, can be cut into flat sheets or rolled into a complex web.

Paper board pasting machine is classified according to the structure and type of forming device and a drying part, a single long mesh paperboard machine, fourdrinier board machine, combined paperboard machine, multi cylinder board machine, which is the most widely used.

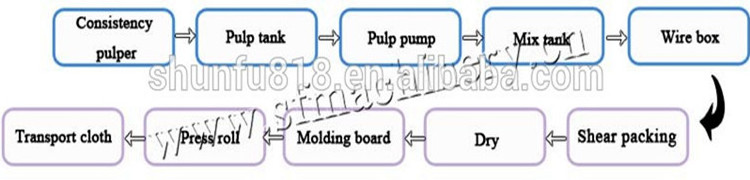

Technological Process

Peformance Parameter

| Thickness of paper | can debugging(1-5mm) |

| Specifications | 1300mm×1000mm |

| Work Speed | 30~50m/min |

| 1set capacity | 10t/d (If you need to add the capacity, you need to buy many sets) |

| Consistency of pulp | 0.8~1% |

| Host power | 5.5kw |

| Appearance size | 9000mm×2500mm×2000mm |

Parts of Paperboard Making Machine

Drying Ways

Our paperboard dry have two dry ways:

- The sun dry the sludge board of product, then use calendar to pressure.

- Use hot pressure machine to dry the sludge board of product,this equipment need boiler.

Hot Pressure Machine: It is composed of a frame, a hot pressing plate and a pressurizing device for oil pump. There are evenly distributed pipes in the hot pressing plate, which are used to circulate heating medium such as superheated steam and oil. The wet paperboard or fiberboard pressed by the press machine is tiled on each hot pressing board. At the same time, the oil pump is used to boost the pressure to make the water evaporate, and the dry and compact finished products can be obtained.

Compare two kinds price, the second is more expensive than the first.

Raw Materials & Finished Products

The installing issue: Shunfu will send engineers to customers' place. The customer should help installation, the engineer is responsible for installation, testing and training for about 30 days. Below is some picture of installation case for your reference:

--Full Automatic Paper Board Machine Production Line to Jordan--

--Semi Automatic Paper Board Machine to Malaysia--

--Semi Automatic Paper Board Machine To Uzbekistan--