- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

234-455-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JULIANG

-

Model Number:

-

WJPG-398

-

Appearance:

-

Yellowish Powder

-

Particle size:

-

10-30um

-

Main usage:

-

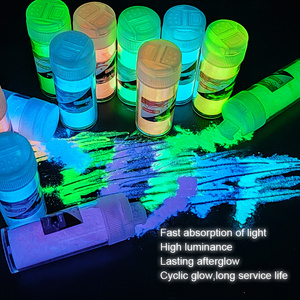

ink, painting, plastice, cosmetic, silicone product

-

Life:

-

15 years

-

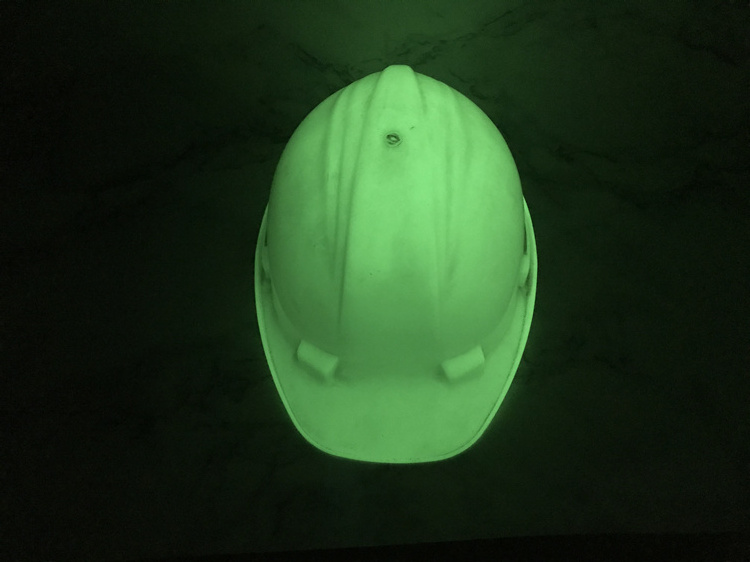

Glowing color:

-

Green

-

Resist temperature:

-

800 celsius degree

-

Feature:

-

glowing in the dark

-

Safety:

-

Non-toxic, harmless, Non-radiation

Quick Details

-

CAS No.:

-

12004-37-4

-

Other Names:

-

Photoluminescent Pigment

-

MF:

-

SrAl2O4:Eu, Dy

-

EINECS No.:

-

234-455-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JULIANG

-

Model Number:

-

WJPG-398

-

Appearance:

-

Yellowish Powder

-

Particle size:

-

10-30um

-

Main usage:

-

ink, painting, plastice, cosmetic, silicone product

-

Life:

-

15 years

-

Glowing color:

-

Green

-

Resist temperature:

-

800 celsius degree

-

Feature:

-

glowing in the dark

-

Safety:

-

Non-toxic, harmless, Non-radiation

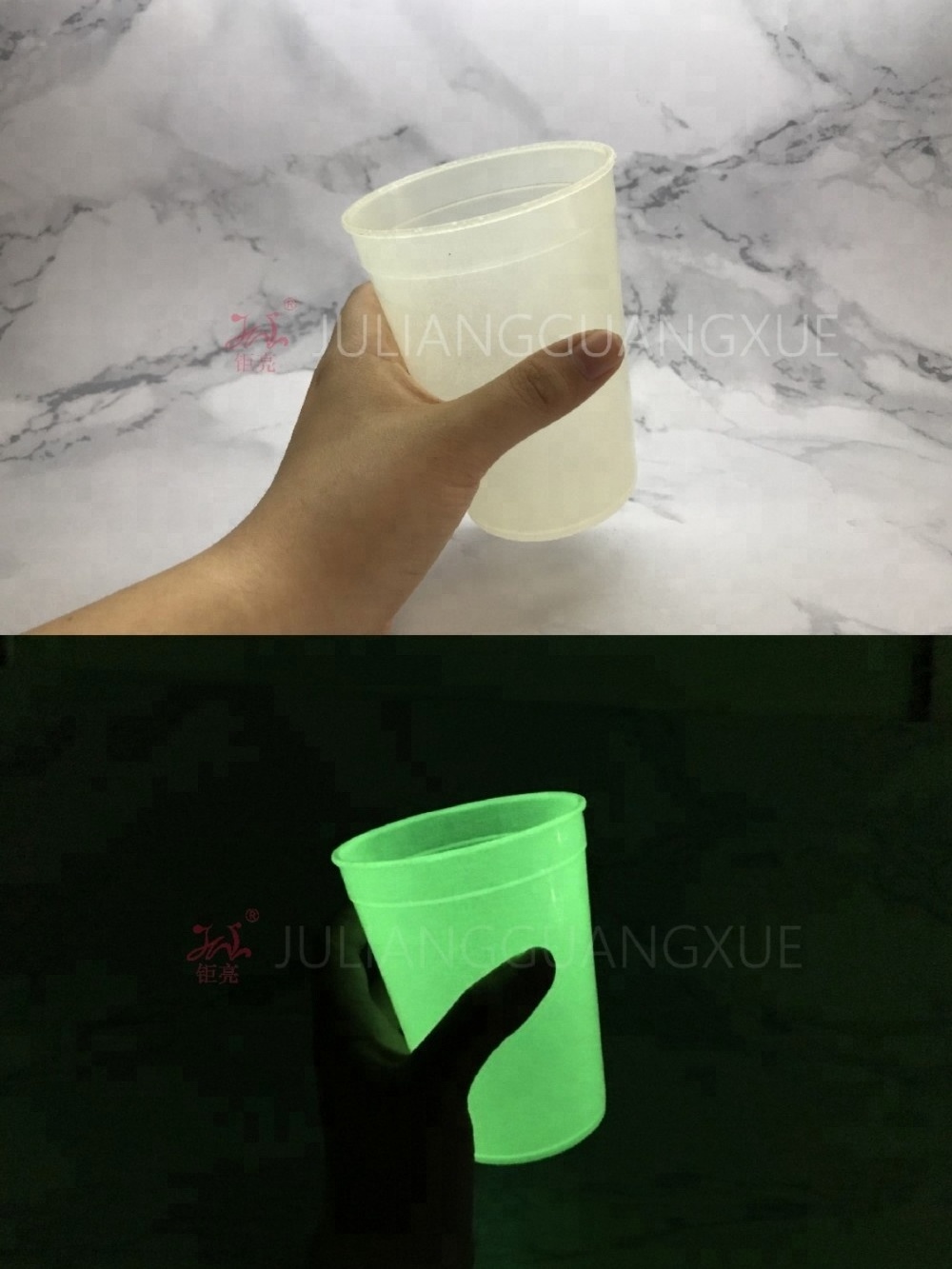

injection molding glow in the dark powder

Products details:

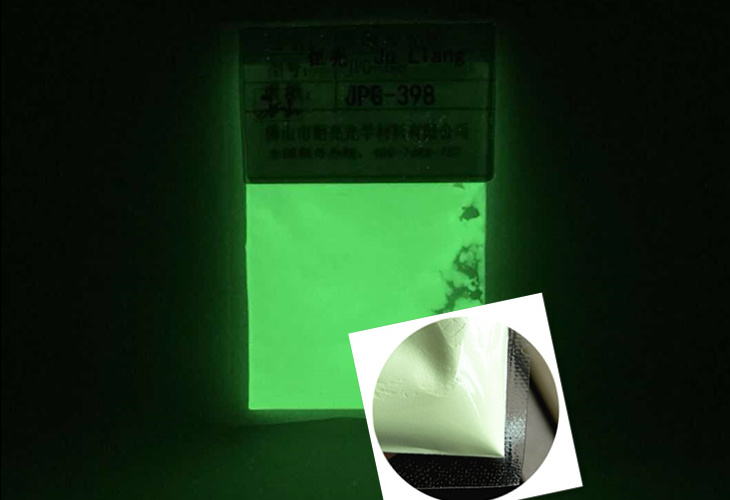

1. Model: WJPG-398

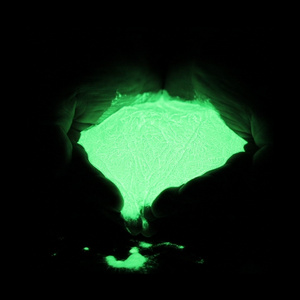

2. Color: yellow-green in the dark, is yellowish in the day.

3. Intensity afterglow: 5217—1min, 770—10mins, 102—60mins.

4. Features: non-toxic, non-radiation, harmless, Tasteless, absorbing light time is short, afterglow time is long. easy to get light source. stable physical and chemical characteristics.

5. Other glowing color: click here.

Application: Glow in the dark powder for injection molding.

Have you ever met the phenomenon of blackening in the injection? How to avoid this phenomenon?

1. The firstly, To choose the finer particle size, softer powder.

2. Secondly, we should try to use An old, short screw injection machine (which is generally recommended to be within 0.8 meters) to make luminous products better.

3. The thirdly, as far as possible to mix by hand, to avoid machine mixing.

4. In the process of injection molding as far as possible to improve the temperature of the front section, When the finished product is to be finished as far as possible to lower the post temperature and pressure.

5. At last, the proportion of glow powder used for injection is generally 3%-10%. The proportion can be adjusted according to the requirement of brightness and cost accounting, but it is best to add proportion to no more than 10%.

Note: to pay attention in the mixture, it is better to add some diffusion oil first, and the proportion is about 5 ‰ , for dispersing glow powder, let the glow powder evenly touch the surface of the material. Glow powder agglomerates will lead to a certain period of time to a large number of luminous powder inside the barrel, which will increase the friction between the screw and the luminous powder, so that it will be very prone to the phenomenon of black.

| 1kg-100kg | by FEDEX, DHL express | About 6-7 days |

| 1kg-100kg | by FEDEX, DHL common air | About 15-20 days |

| 100kg-500kg | by FEDEC, DHL express and common air | About6-7 days,15-20 days |

| 100kg-500kg | by sea | About 30 days |

1. We can provide sample customization services.

2. We can provide your packaging and label.

3. We can provide technical guidance.