roll forming roller stations :20 sets

Straightening rollers:1 set

The roll forming part with Emergency stop device .Hardness:HRC55(The surface is smooth and does not scratch the product.)

Roller Model Material: Cr12MoV,Quenching hardnesHRC55,electric processing

Roller diameter:39mm

Roll forming speed:30m/min(including the punching)

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HuaYang

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

3500*1000*1200mm

-

Weight:

-

2.5 kg

-

Name:

-

track drywall omega main channel roll forming framing machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

steel, GI,PPGI

-

Control system:

-

PLC computer control

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

GCr 12 High Grade Steel

-

Production speed:

-

15-40m/min

-

Cutting power:

-

4 kw

-

Color:

-

Client's Request

-

Usage:

-

Steel Construction

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15-40 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HuaYang

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

3500*1000*1200mm

-

Weight:

-

2.5 kg

-

Name:

-

track drywall omega main channel roll forming framing machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

steel, GI,PPGI

-

Control system:

-

PLC computer control

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

GCr 12 High Grade Steel

-

Production speed:

-

15-40m/min

-

Cutting power:

-

4 kw

-

Color:

-

Client's Request

-

Usage:

-

Steel Construction

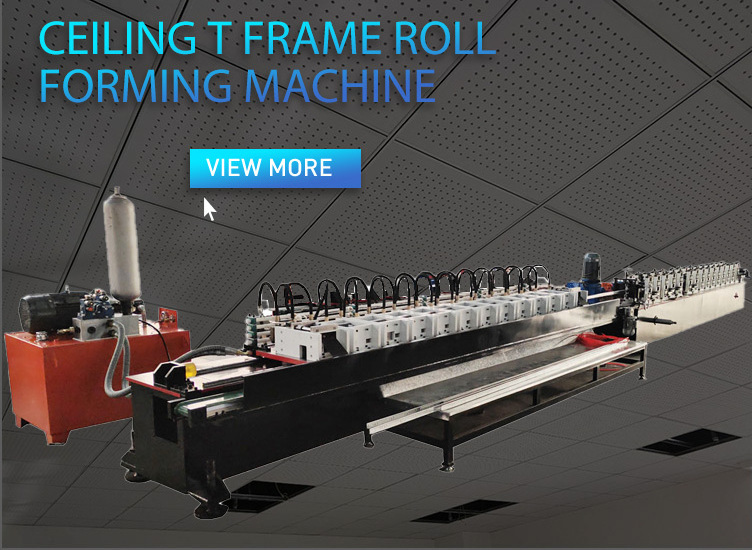

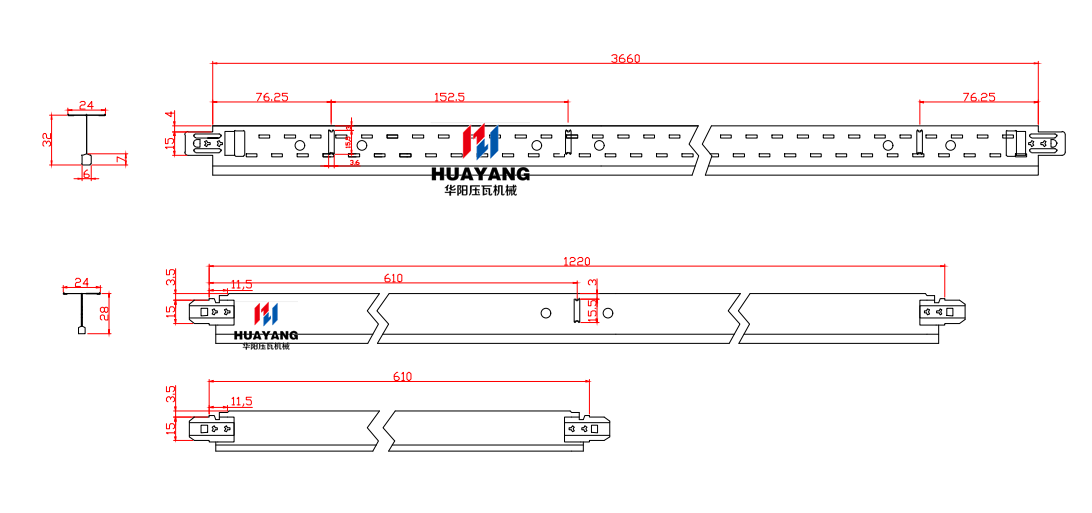

Ceiling T Grid Roll Forming Machine

can be designed with T , that is fut T sheet roll forming machine, with high speed, the punching part can as you need , and raw material thickness of 0.3-0.6mm, which basically meets the needs of the market

.

Ceiling T bars are used as the main keel in the metal false ceiling suspending, normaly is Lay-In Suspend Metal Ceiling, and the frame

used for the ceiling keel functions as a support and decorative panel.

The T grid formed T grid m

aking machine has good overall plane effect, the lines are full automatic,simple and beautiful.The T-shaped keel produced by this T-grid roll forming equipment is widely used in construction and decoration projects.

PRODUCT DISPLAY

PRODUCT DETAILS

|

After-sales Service Provided

|

Engineers available to service machinery overseas

|

|

raw material

|

PPGI

|

|

control system

|

PLC

|

|

warranty

|

18 months

|

|

Cutting blade material

|

Cr12 Quenching

|

|

Roller material

|

45# Forged Steel

|

|

Key Selling Points

|

Easy to operate

|

|

Color

|

Customized

|

servo punching

for the ceiling T frame roll forming machine ,all

Punching model we choose SKD11 with Vacuum heat treatment and the punching work table is Unibody.punching work table thickness at 20mm ,side table thickness at 6mm.surface finish grinding. Side antiseptic treatment.

Roll Forming Machine

double sewing device

double sewing device can roll the steel sheet e

mboss,

Front and back correspondence .which making the sheet straight than normal type .

hydraulic station

Power :15 kw

35P oil cooler is used to control oil temperature

Process:All oil pipes are equipped with steel wires, the motor is 15kw all copper wire temperature resistant motor, and the oil

circuit block is finely ground .

35P oil cooler is used to control oil temperature

Process:All oil pipes are equipped with steel wires, the motor is 15kw all copper wire temperature resistant motor, and the oil

circuit block is finely ground .

APPLICATION

Light steel keel is a new type of building material. With the development of modernization, light steel keel is widely used in hotels, terminals, train stations, stations, playgrounds, shopping malls, factories, office buildings, and old building renovations. , Interior decoration settings, ceilings and other places.

RELATED PRODUCTS

Wall angle profile making machine:

Wall angle profile making machine is composed by decoiler, main roll forming machine, Automatic hydraulic cutting off

station,hydraulic cooling station and electric control system, etc.

- Angle:22*22, 22*20MM

- According with customer’s request

- Thickness:0.3-0.50mm

station,hydraulic cooling station and electric control system, etc.

- Angle:22*22, 22*20MM

- According with customer’s request

- Thickness:0.3-0.50mm

COMPANY PEOFILE

customer test the finished machine in our factory

A:- What is your payment term?

- 30% of the total payment should be paid as deposit ,the balanced should be paid after check the finished photos and videos well ,we supply test report.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- 24 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

E:- Can you accept OEM?

- We can accept OEM

- 30% of the total payment should be paid as deposit ,the balanced should be paid after check the finished photos and videos well ,we supply test report.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- 24 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

E:- Can you accept OEM?

- We can accept OEM

Hot Searches