- Product Details

- {{item.text}}

Quick Details

-

Technology:

-

investment casting

-

Mainly metal:

-

stainless steel,carbon steel,brass, copper, bronze

-

Casting tolerance:

-

CT4-CT6

-

Roughness:

-

Ra 3.2-Ra12.5 (GB/T 6060.1)

-

Certificate:

-

ISO

-

Machining:

-

CNC machining, milling, drilling, tapping

-

Heat treatment:

-

quenchining, tempering, annealing, normalizing

-

Surace Treatment:

-

electropolishing, mirror polishing, electrogalvanizing

-

Standard:

-

ANSI, ASTM, AISI, GB, DIN, JIS

-

Lead Time:

-

15-35 Days

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Customized lost wax casting

-

Model Number:

-

OEM

-

Technology:

-

investment casting

-

Mainly metal:

-

stainless steel,carbon steel,brass, copper, bronze

-

Casting tolerance:

-

CT4-CT6

-

Roughness:

-

Ra 3.2-Ra12.5 (GB/T 6060.1)

-

Certificate:

-

ISO

-

Machining:

-

CNC machining, milling, drilling, tapping

-

Heat treatment:

-

quenchining, tempering, annealing, normalizing

-

Surace Treatment:

-

electropolishing, mirror polishing, electrogalvanizing

-

Standard:

-

ANSI, ASTM, AISI, GB, DIN, JIS

-

Lead Time:

-

15-35 Days

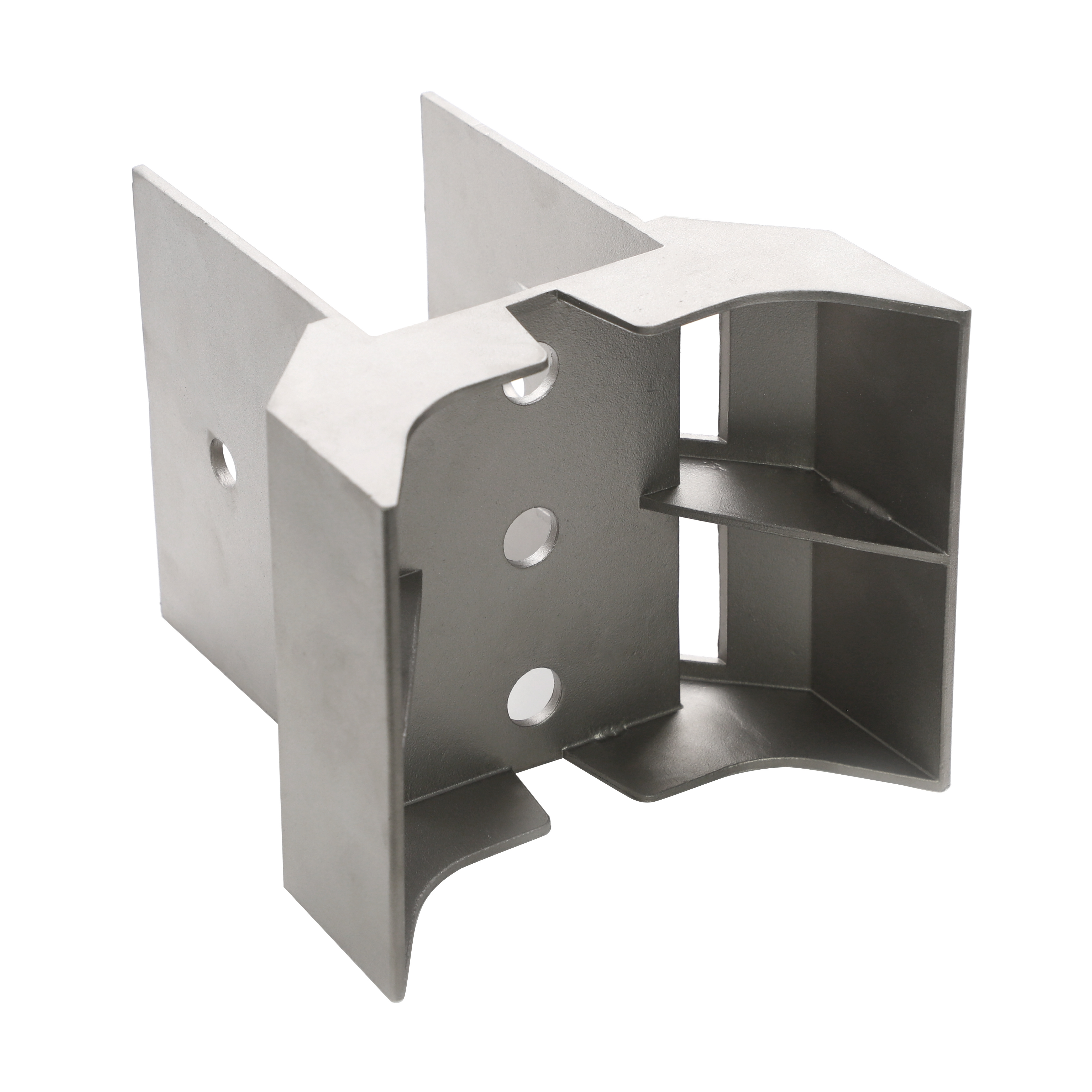

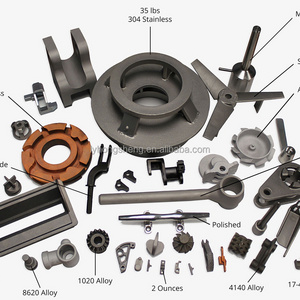

Product Dispaly

|

Materials

|

Stainless Steel/carbon steel, brass, bronze

|

|

Technology

|

Investment casting, Precision Casting, Lost wax casting

|

|

Machining

|

Turning, cutting, milling, grinding and drilling

|

|

Surface Treatment

|

Sand blasting, Powder coating, Painting, Anodizing, Polishing...

|

|

Weight

|

0.01kg--50kg

|

|

Casting Tolerance

|

GBT CT4-CT6

|

|

Machining Tolerances

|

≥0.01mm

|

|

OEM/ODM parts range

|

Auto parts, electronic parts, furniture parts, home appliance and other industrial uses

|

Casting Process

1.Lead Time

Mold: 15 Days

Casting Samples: 7-10 Days

Mass Production: 25-30 Days (According to the quantity and process)

2.Production Process Flow

Wax Injection--Wax repairing--Wax Tree--Cleaning--Shell Making--Drying--Dewaxing--Smelt & Pouring--Shot

Blasting--Chamfering--Repairing--Shaping--CNC Machining--Inspecting

Wax Injection--Wax repairing--Wax Tree--Cleaning--Shell Making--Drying--Dewaxing--Smelt & Pouring--Shot

Blasting--Chamfering--Repairing--Shaping--CNC Machining--Inspecting

3.Disadvantage

1. Higher dimensional accuracy of castings, generally up to CT4-6 (Generally, CT10-13 for sand casting and CT5-7 for die casting)

2. Better surface finish than that of general castings, generally up to Ra.1.6~3.2μm.

3. Saving additional cost . Due to the high dimensional accuracy and surface finish of investment castings, products can be used without machining.

4. Casting complex shape in various alloys.

5.

Short

mold manufacturing time and

fast delivery time

QA&QC

Package&Shipping

Our products are all packed in wooden cases to ensure zero damage.

Packaging:

1.Wooden

2.Plastic

3.Pallet

As customers request

Packaging:

1.Wooden

2.Plastic

3.Pallet

As customers request

FAQs

1.How can I get the quotation?

Please give us your drawing,quantity,weight and material of the product.

2.If you don't have the drawing,can you make drawing for me?

Yes,we are able to make the drawing of your sample duplicate the sample.

3.When can I get the sample and your main order time?

Sample time: 35-40 days after start to make mold. Order time: 35-40 days, the accurate time depends on product.

4.What is your payment method?

Tooling:100% T/T advanced Order time:50% deposit,50%to be paid before shipment.

5.Which kind of file format you can read?

PDF, IGS, DWG, STEP, MAX

6.What is your surface treatment?

Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip

galvanizing, electrophoresis, chrome plating.

7.What is your way of packing?

Normally we pack goods according to customers' requirements.

Please give us your drawing,quantity,weight and material of the product.

2.If you don't have the drawing,can you make drawing for me?

Yes,we are able to make the drawing of your sample duplicate the sample.

3.When can I get the sample and your main order time?

Sample time: 35-40 days after start to make mold. Order time: 35-40 days, the accurate time depends on product.

4.What is your payment method?

Tooling:100% T/T advanced Order time:50% deposit,50%to be paid before shipment.

5.Which kind of file format you can read?

PDF, IGS, DWG, STEP, MAX

6.What is your surface treatment?

Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip

galvanizing, electrophoresis, chrome plating.

7.What is your way of packing?

Normally we pack goods according to customers' requirements.

Hot Searches