- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Weight:

-

0.08 KG

-

Material:

-

96 Alumina ceramic

-

Core Components:

-

Heating core

-

Product name:

-

High temp resistance mch alumina ceramic heating heaters disc elements

-

Shape:

-

Ring

-

Size:

-

OD24*ID4*T1.3mm

-

Energy power:

-

Electric

-

Function:

-

Heating

-

Resistance:

-

8~10Ω, 11~14Ω, 18~22Ω, 30~40Ω

-

Voltages available:

-

12V 24V 36V 48V

-

Features:

-

Environmental, high efficiency, long uselife

-

Certificate:

-

ISO900, RoHS

-

Customization:

-

Support

Quick Details

-

Type:

-

Other

-

Power Source:

-

Electric

-

Voltage:

-

Various

-

Place of Origin:

-

China

-

Weight:

-

0.08 KG

-

Material:

-

96 Alumina ceramic

-

Core Components:

-

Heating core

-

Product name:

-

High temp resistance mch alumina ceramic heating heaters disc elements

-

Shape:

-

Ring

-

Size:

-

OD24*ID4*T1.3mm

-

Energy power:

-

Electric

-

Function:

-

Heating

-

Resistance:

-

8~10Ω, 11~14Ω, 18~22Ω, 30~40Ω

-

Voltages available:

-

12V 24V 36V 48V

-

Features:

-

Environmental, high efficiency, long uselife

-

Certificate:

-

ISO900, RoHS

-

Customization:

-

Support

|

High temp resistance mch alumina ceramic heating heaters disc elements

|

5,000 Hours

20,000 Hours

50,000 Hours

(Based on use condition)

|

Voltage

|

DC 3.7V / 5V

DC 12V / 24V

AC 110V / 220V

AC 230V / 240V / 360V

|

|||

|

Model No.

|

H240413

|

Main material

|

96% alumina ceramic

|

|||

|

Shape

|

Ring

|

Size

|

OD24*ID4*T1.3mm

|

|||

|

Energy power

|

Electric

|

Voltage

|

Various

|

|||

|

Item Name

|

Ceramic heater element

|

Function

|

Heating

|

|||

|

Resistance

|

8~10Ω, 11~14Ω, 18~22Ω, 30~40Ω

|

Certificate

|

ISO9001, RoHS

|

|||

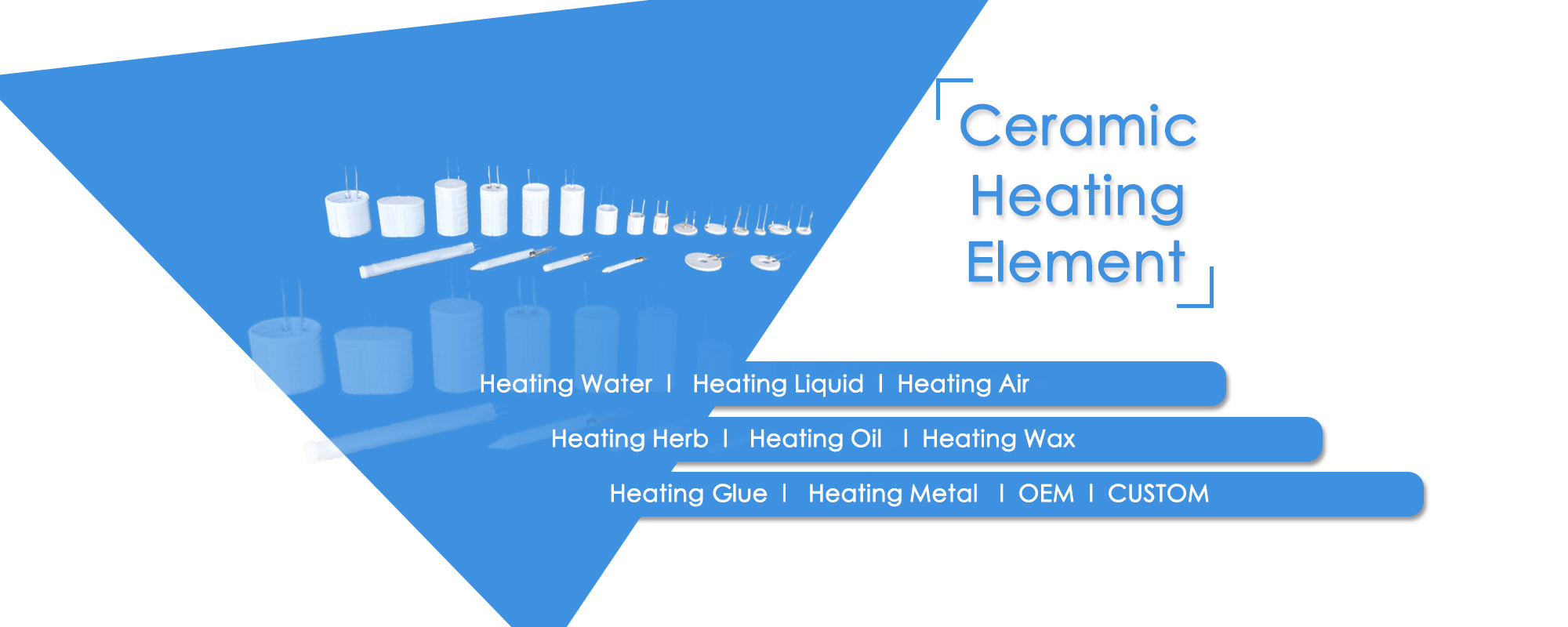

AlN heating element (Aluminum nitride heating element)

Zirconia ceramic heating element

Some other alumina ceramic heating elements

Porous ceramic heating element

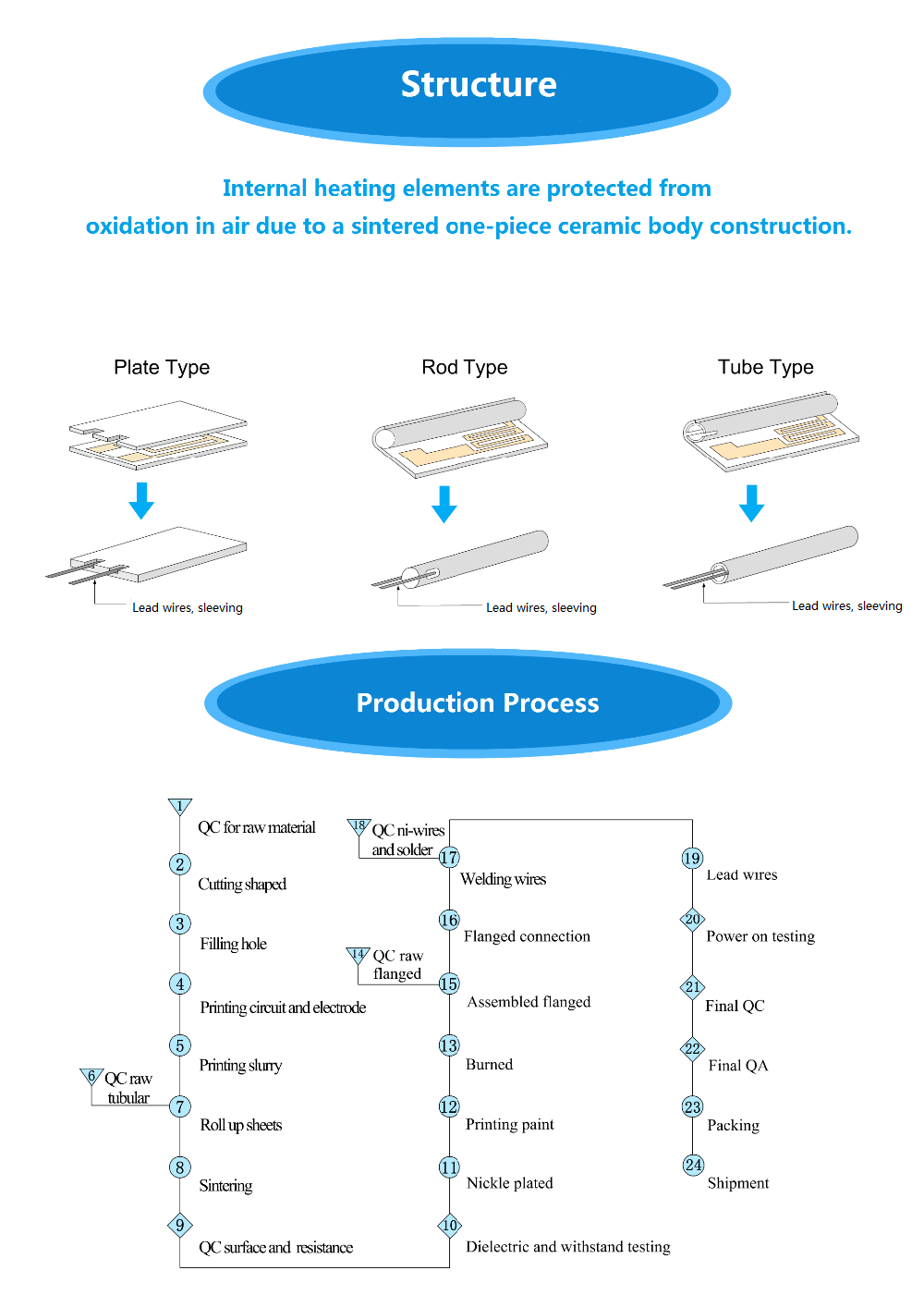

Zhuhai MW Technology Co., Ltd. was founded in 2017. As an innovative developer and manufacturer of MCH ceramic heating elements and printed circuits using IC technology, MW owns its R&D department, clean room, advanced printing equipment, furnace and patent-protected inventions.

MW adheres to technological innovation and has been focusing on the development and manufacturing of electronic ceramics and related ceramic components. The current production of MCH electric ceramic heating elements with plate-shaped, special-shaped, rod-shaped and other shapes are widely used as the important heating components in large and small household appliances such as air conditioners, fan heaters, and hair straighteners, etc.

At present, we have 5 kiln production lines and the monthly production capacity is about 500,000pcs. Through the sincere cooperation of our team, the benefits have increased significantly in the past two years, and the product quality has been well received by the majority of customers.

Looking to the future, we’ll continue to adhere to the management philosophy of "people-oriented, innovative development" , the service purpose of "customer first, reputation first" , and the development goal of "achievements of enterprises, talent training, service society" . We’ll take the market as the guide, take the science and technology development as the theme, take the excellence to be the first as the opportunity, and commit to the development and introduction of domestic advanced manufacturing technology to serve the domestic and foreign markets, to ensure the product quality, technical level, service level in the domestic industry to maintain a leading position.

High temp resistance mch alumina ceramic heating heaters disc elements will be packed well before shipment to prevent damage. We usually ship our MCH ceramic heating components by DHL. But we could change the shipment according to your need.

1. Should pay attention to the surface of ceramic heater to avoid stained with oil, dirty such as the waterproof when installation, which to avoid ceramic heater damage because of its poor heat dissipation. 2. The working environment of ceramic heater is prohibited excessive heat and cold, which to prevent cold and hot shock damage. 3. The working voltage of ceramic heater should be controlled within the range of the rated voltage in order to prevent the ceramic heater from load and affect the service life. 4. Ceramic heater when heating in the water or liquid. It should be forbidden to add water after dry suddenly, all the heating pats in the container must be completely submerged in the water, the water level should over the heat element, otherwise it’ll cause heating element fracture and damage. 5. Ceramic heater should be perpendicular to the cavity when installation, otherwise the surface temp will not uniformity and make the bubbles which will make the part heat and make the heater broke 6. When ceramic heater is working, power on after watering to prevent dry heat.

1. Can the product be customized? Yes.Both OEM and ODM are available. 2. Do you support sample order? Most of current items stock are available. Customized support. 3. What's your after sales? We will track the product logistics until you get the product. When you receive the goods, please test the product and give us feedback.And we will provide solutions based on your feedback. Please contact for more details.

Rita Yang Zhuhai MW Technology Co., Ltd. Tel: +86 0756 3689220 Fax: +86 0756 3689309 Email: rita@mwheater.com Phone/ WhatsApp: +86 136 31275331 Skype: ritatoday