- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

20-30kg

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

THRIVE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1020*700*1200mm

-

Power (kW):

-

2.2 kW

-

Usage:

-

Chemicals mixer

-

Keyword:

-

Power mixer

Quick Details

-

Barrel Volume (L):

-

50

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

1 - 33 r.p.m

-

Max. Loading Capacity:

-

20-30kg

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

THRIVE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1020*700*1200mm

-

Power (kW):

-

2.2 kW

-

Usage:

-

Chemicals mixer

-

Keyword:

-

Power mixer

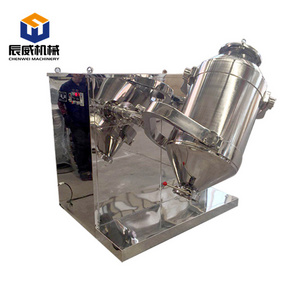

small drum powder mixer/stainless steel drum food dry mixer/powder mixing machine

Stainless steel mixer is a new, highly effective, fine waist drum type container rotary type, stirring mixing equipment, used for mixing of powdery and granular materials, has the very high mixing degree, to add small amounts of ingredients can also achieve good mixing degree, the machine adopts mechanical seal, powder will not leak, long service life of bearing. This machine has high mixing efficiency, high working efficiency, high working efficiency, low labor intensity and convenient operation. Can be used in magnetic powder, ceramics, chemical, feed and other industries.

Principle of food drum mixer

The mixer rotates 360 degrees, turns over, and there is a mixing blade in the middle of the mixer. When the mixer is running, the mixing blade rotates at the same time. The rotating double-cone barrel makes the materials in the cylinder tumble and mix in disorder. The high-speed rotating mixing blade breaks up the agglomerated materials and makes the materials mix in the cylinder rapidly.

Product use

1. Metal powder: aluminum, zinc, lead, copper, iron, nickel, alloy, magnetic materials and other metals are powder.

2. Chemical materials such as resin, plastics, banana auxiliaries, fuels, pesticide fillers, etc.

3. Foods designed in line with health standards: flour, cocoa, coffee, condiments, additives, etc.

4. Grain grain, corn, beans, sesame and other crops selection, shell, miscellaneous.

5. Abrasive: glass beads, alumina, corundum, carbon chloride, emery, quartz sand and other abrasive materials.

Feed processing powder, particles, additives, etc.

6. Screening of fertilizer raw materials and other products.

7. Screening of finished products after machine processing of raw powder of various mineral species.

8. Fibrous materials: wood chips, wood powder, charcoal, activated carbon, carbon black and other fibrous materials.

9. Recycling and utilization of various materials and resources such as welding materials, refractory materials and phosphors.

Parameters

| model | Package size(CM) | voltage | power | Weight |

| 50L | 120*95*125cm | 220V/380V | 2.2KW | 150kg |

| 100L | 125*100*125cm | 220V/380V | 2.2KW | 200kg |

| 200L | 138*125*146cm | 220V/380V | 3KW | 250kg |

| 400L | 146*140*162cm | 220V/380V | 3KW | 300kg |

We also have other kinds mixer

Please check the following picture , You also can click the picture to get more information

Lab use mixer

Horizontal mixer

3D mixer

Liquid mixer

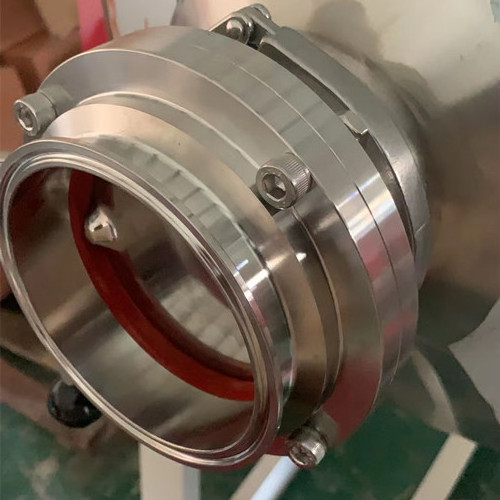

Buying a machine is like buying something else, there is an issue that customers are very concerned about. Should we choose price or quality. The following picture compares the elevators from other factories with those from our factory, and you can see the difference from the picture.

This is the elevator from other factory and the leakage suitation is very serious

This is the machine from our factory

Contact with our sales manager to get the machine test video compare

If you want to use the machine in your own factory and just want to save money , you can choose the cheaper one.That is your choice .

If you are the reseller , when the situation of material leakage exist, you need to consider how to explain it to your customer