- Product Details

- {{item.text}}

Quick Details

-

Thickness:

-

5mm-60mm

-

Size:

-

600*1200mm,1000*1000mm,1200*1200mm and 1000*2000mm

-

Name:

-

engineering plastic pom sheet

-

Certificate:

-

CE, ISO9001:2008

-

Density:

-

1.45 g/cm3 - 1.5 g/cm3

-

Flammability:

-

Self-extinguishing

-

Color:

-

White,Black,etc.

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ODSN

-

Model Number:

-

POM sheet

-

Thickness:

-

5mm-60mm

-

Size:

-

600*1200mm,1000*1000mm,1200*1200mm and 1000*2000mm

-

Name:

-

engineering plastic pom sheet

-

Certificate:

-

CE, ISO9001:2008

-

Density:

-

1.45 g/cm3 - 1.5 g/cm3

-

Flammability:

-

Self-extinguishing

-

Color:

-

White,Black,etc.

Products Description

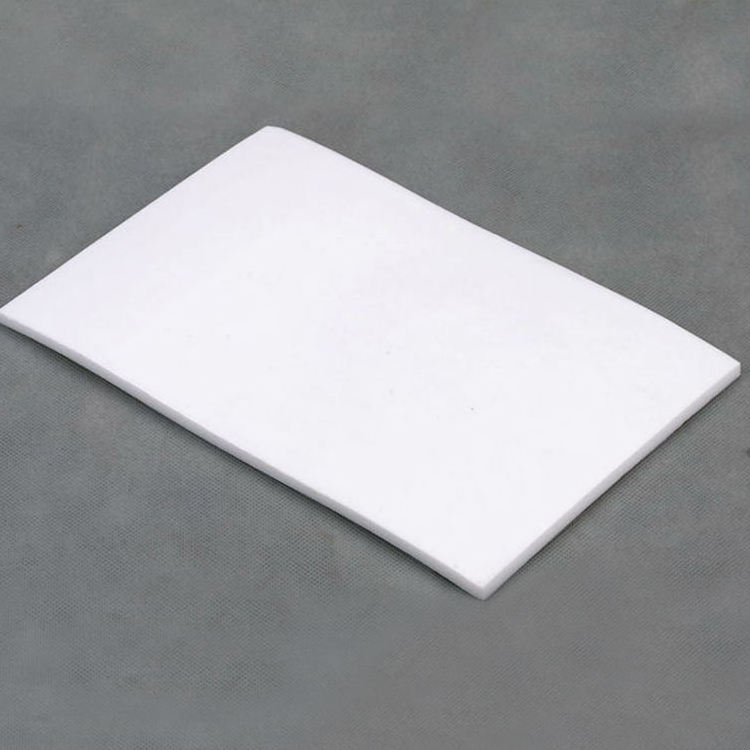

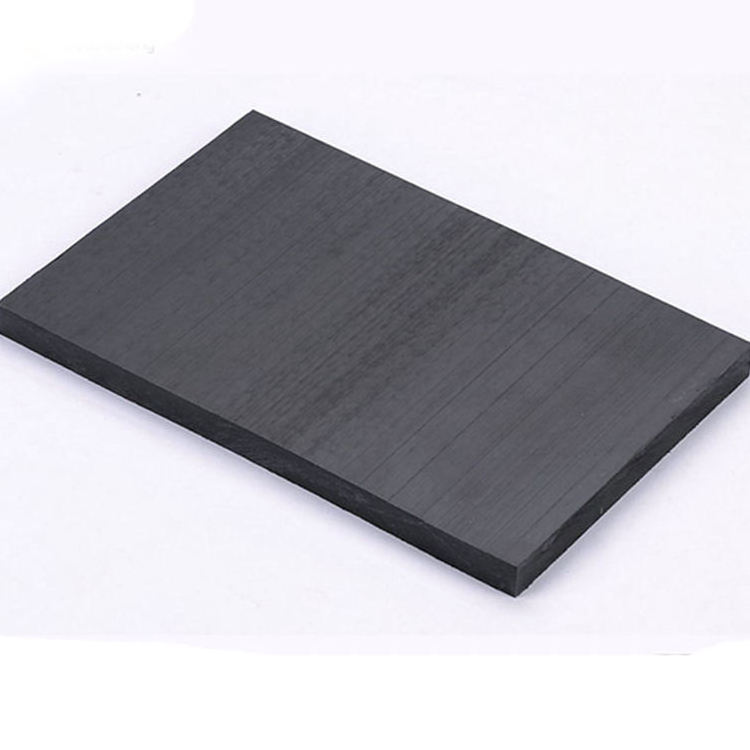

Appearance

Smooth surface without bubbles

Color: WHITE,BLACK or custom-made according to customers’ requirements.

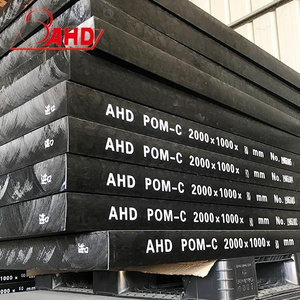

Plate:Thickness: 6mm-100mm

Sizes: 600mm*1200mm,1000mm*1000mm,1000mm*2000mm

Sticks:Diameter: 5-250mm

Length: 1000MM

Density : 1.5-1.6 g/cm3

Polyoxymethylene sheet is also named as POM sheet.

POM is a cream-colored thermoplastic resin which is very excellent physical and mechanical properties. It has the follow features:

1.Good overall performance,and coloration,high strength reach to metal.

2.Tensile strength,flexural strength,creep resistance and fatigue resistance.

3.Low coefficient of friction.

4.Excellent chemical resistance.

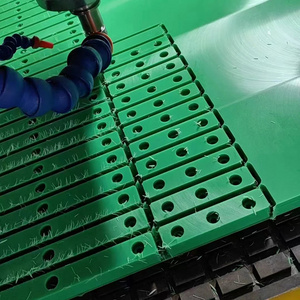

Applications:

POM is widely applying to cars,electronics,clothing,medical treatment,machinery and so on.

For producing all kinds of sliding rotating machineries,precision parts,gears and bearings etc.

|

POM Certificate Of Quality

|

|

|

|

|

|

|||||

|

Items

|

|

Test situation

|

Test method

|

Test data

|

Unit

|

|||||

|

Basic property

|

Density

|

|

ASTM D792

|

1.42

|

g/cm3

|

|||||

|

|

Water absorb

|

24hrs soak +73℉(+23℃)

|

ASTM D570

|

0.25

|

%

|

|||||

|

|

Water absorb

|

Equi1.50%R.h.+73℉(+23℃)

|

ASTM D570

|

0.22

|

%

|

|||||

|

|

Water absorb

|

Soak F point +73℉(+23℃)

|

ASTM D570

|

0.9

|

%

|

|||||

|

Mechanical property

|

No notch impact strength

|

23℃

|

D256

|

>5300

|

j/m

|

|||||

|

|

Compression elasticity

|

73°F@10%Def.

|

ASTM D695

|

18

|

Mpsi

|

|||||

|

|

Compression elasticity

|

23℃@10%Def.

|

ASTM D695

|

124

|

Mpa

|

|||||

|

|

Deformation on load

|

2000psi@+122□H(14Mpa@50℃)

|

ASTM D621

|

0.5

|

%

|

|||||

|

|

Curving surrenders strongly

|

73℉

|

ASTM D671

|

4.7

|

Mpsi

|

|||||

|

|

Curving surrenders strongly

|

23℃

|

ASTM D671

|

32.4

|

Mpa

|

|||||

|

|

lzod impact strength

|

40℉

|

ASTM D256

|

1.8

|

ft.lb/in

|

|||||

|

|

lzod impact strength

|

40℃

|

ASTM D256

|

96.1

|

j/m

|

|||||

|

|

lzod impact strength

|

73℉

|

ASTM D256

|

2.3

|

ft.lb/in

|

|||||

|

|

lzod impact strength

|

23℃

|

ASTM D256

|

123

|

j/m

|

|||||

|

|

Tensile impact resistance

|

73℉

|

D1822Long

|

170

|

ft.lb/in2

|

|||||

|

|

Tensile impact resistance

|

23℃

|

D1822Long

|

350

|

Kj/m

|

|||||

|

|

No notch impact strength

|

73℉

|

ASTM D256

|

>100

|

ft.lb/in

|

|||||

|

|

Tensile Strength rate

|

68℉(-55℃)

|

ASTM D638

|

38

|

%

|

|||||

|

|

Tensile Strength rate

|

73℉(+23℃)

|

ASTM D638

|

75

|

%

|

|||||

|

|

Tensile Strength rate

|

158℉(+70℃)

|

ASTM D638

|

230

|

%

|

|||||

|

|

Tensile Strength rate

|

212℉(+100℃)

|

ASTM D638

|

>260

|

%

|

|||||

|

|

Tensile Strength rate

|

250℉(+122℃)

|

ASTM D638

|

>260

|

%

|

|||||

|

|

Elasticity range

|

68℉

|

ASTM D638

|

14.7

|

Mpsi

|

|||||

|

|

Elasticity range

|

55℃

|

ASTM D638

|

101

|

Mpa

|

|||||

|

|

Elasticity range

|

73℉

|

ASTM D638

|

10

|

Mpsi

|

|||||

|

|

Elasticity range

|

158℉(+70℃)

|

ASTM D638

|

6.9

|

Mpsi

|

|||||

|

|

Elasticity range

|

70℃

|

ASTM D638

|

47.5

|

Mpa

|

|||||

|

|

Elasticity range

|

212℉

|

ASTM D638

|

5.2

|

Mpsi

|

|||||

|

|

Elasticity range

|

100℃

|

ASTM D638

|

35.9

|

Mpa

|

|||||

|

|

Elasticity range

|

250℉

|

ASTM D638

|

3.8

|

Mpsi

|

|||||

|

|

Elasticity range

|

122℃

|

ASTM D638

|

26.2

|

Mpa

|

|||||

|

|

Elasticity coefficient

|

73℉

|

ASTM D638

|

450

|

Mpsi

|

|||||

|

|

Elasticity coefficient

|

23℃

|

ASTM D638

|

3100

|

Mpa

|

|||||

|

|

Shearing force

|

73℉

|

ASTM D732

|

9.5

|

Mpsi

|

|||||

|

|

Shearing force

|

23℃

|

ASTM D732

|

65.5

|

Mpa

|

|||||

|

|

Winding coefficient

|

68℉

|

<25℃

|

530

|

Mpsi

|

|||||

|

|

Winding coefficient

|

55℃

|

<25℃

|

3650

|

Mpa

|

|||||

|

|

Winding coefficient

|

73℉

|

<25℃

|

380

|

Mpsi

|

|||||

|

|

Winding coefficient

|

23℃

|

<25℃

|

2620

|

Mpa

|

|||||

|

|

Winding coefficient

|

158℉

|

<25℃

|

225

|

Mpsi

|

|||||

|

|

Winding coefficient

|

70℃

|

<25℃

|

1550

|

Mpa

|

|||||

|

|

Winding coefficient

|

212℉

|

<25℃

|

130

|

Mpsi

|

|||||

|

|

Winding coefficient

|

100℃

|

<25℃

|

895

|

Mpa

|

|||||

|

|

Winding coefficient

|

250℉

|

<25℃

|

90

|

Mpsi

|

|||||

|

|

Winding coefficient

|

122℃

|

<25℃

|

620

|

Mpa

|

|||||

|

|

Curving surrenders strongly

|

|

ASTM D790

|

14.3

|

Mpsi

|

|||||

|

|

Curving surrenders strongly

|

218℉

|

ASTM D790

|

98.6

|

Mpa

|

|||||

|

|

Compression elasticity

|

|

ASTM D695

|

5.2

|

Mpsi

|

|||||

|

|

Compression elasticity

|

|

ASTM D695

|

35.9

|

Mpa

|

|||||

|

|

Tensile Strength

|

|

ASTM D-638

|

68.9

|

Mpa

|

|||||

|

|

Rockwell hardness

|

|

ASTM D785

|

M94,R120

|

|

|||||

|

Physical property

|

Insulation Strength

|

Short Time,90mils

|

ASTM D149

|

500

|

V/mil

|

|||||

|

|

Insulation Strength

|

Short Time,2.3mm

|

ASTM D149

|

1.97

|

MV/m

|

|||||

|

|

Friction coefficient

|

+73℉(+23℃)Static

|

|

0.20

|

washertest3

|

|||||

|

|

Friction coefficient

|

+73℉(+23℃)Dynamic

|

ThrustWasher

|

0.35

|

|

|||||

|

|

Resistance coefficient

|

+73℉(+23℃)0.2%H20

|

ASTM D257

|

10 15

|

Ohm-cm

|

|||||

|

|

Insulation Strength

|

Coefficient+73℉(+23℃)102to106Hz

|

ASTM D150

|

3.7

|

|

|||||

|

|

Diffusion factor

|

+73℉(+23℃)10^6Hz

|

ASTM D150

|

0.005

|

|

|||||

|

Electricity property

|

Arc resistivity

|

120mil(3.1mm)

|

ASTM D495

|

220no tracking

|

sec

|

|||||

|

|

Hot deformation temperature

|

0.5Mpa

|

ASTM D648

|

172

|

℃

|

|||||

|

|

Hot deformation temperature

|

1.8Mpa

|

ASTM D648

|

136

|

℃

|

|||||

|

|

Hot deformation temperature

|

66psi

|

ASTM D648

|

342

|

℉

|

|||||

|

|

Hot deformation temperature

|

264psi

|

ASTM D648

|

277

|

℉

|

|||||

|

|

Melting point

|

|

ASTM D2133

|

347

|

℉

|

|||||

|

|

Melting point

|

|

ASTM D2133

|

175

|

℃

|

|||||

|

|

linear thermal expansion coefficient

|

-40to+85℉

|

ASTM D696

|

5.8

|

10-5in/in.℉

|

|||||

|

|

linear thermal expansion coefficient

|

-40to+85℉

|

ASTM D696

|

10.4

|

10-5m/m℃

|

|||||

|

|

linear thermal expansion coefficient

|

-85to+140℉

|

ASTM D696

|

6.8

|

10-5in/in.℉

|

|||||

|

|

linear thermal expansion coefficient

|

-29to+60℃

|

ASTM D696

|

12.2

|

10-5m/m℃

|

|||||

|

|

linear thermal expansion coefficient

|

-140to+122℉

|

ASTM D696

|

7.6

|

10-5in/in.℉

|

|||||

If you can't find which one you need

please send us an inquiry for details

Click to contact us>>

Product Category

Hot Searches