As an ISO 9001:2015 Company, Wotech is globally recognized as one of the professional supplier. The products are widely used in Automotive, Railway and Mechanical Industry.

- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Spinning Products

-

Material:

-

Zinc, Aluminium

-

Size:

-

Customized

-

Surface Treatment:

-

Self Color Anodizing

-

Style:

-

Classic

-

Usage:

-

Machinery

-

Logo:

-

Screen Printing

-

Drawing:

-

Available

-

Sample:

-

Available

-

Certificate:

-

ISO9001

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WOTECH

-

Model Number:

-

OEM

-

Product Name:

-

Spinning Products

-

Material:

-

Zinc, Aluminium

-

Size:

-

Customized

-

Surface Treatment:

-

Self Color Anodizing

-

Style:

-

Classic

-

Usage:

-

Machinery

-

Logo:

-

Screen Printing

-

Drawing:

-

Available

-

Sample:

-

Available

-

Certificate:

-

ISO9001

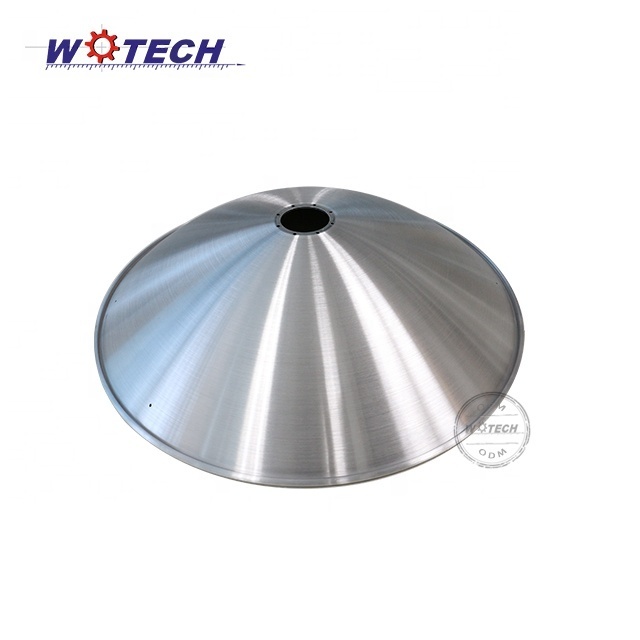

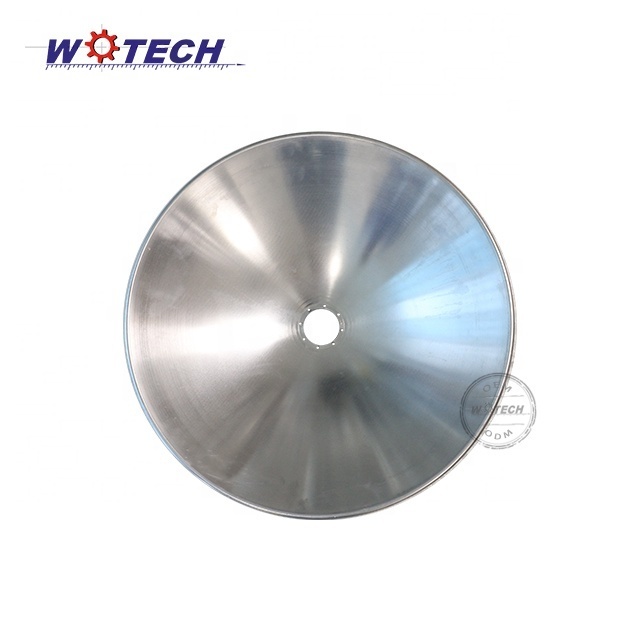

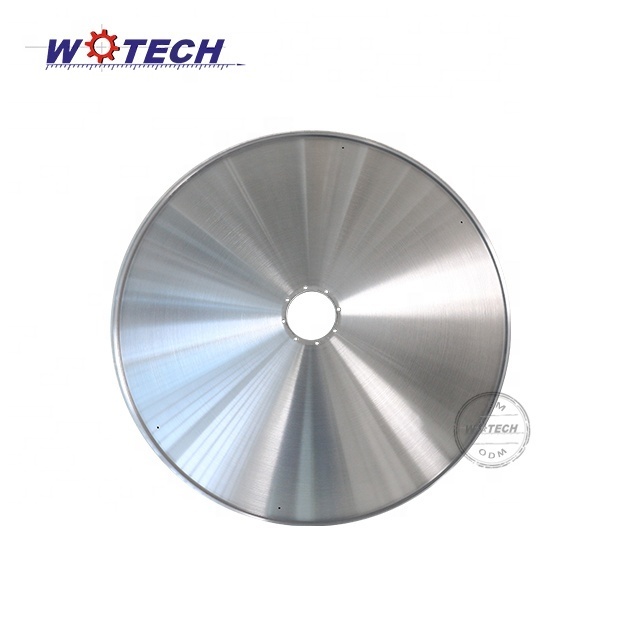

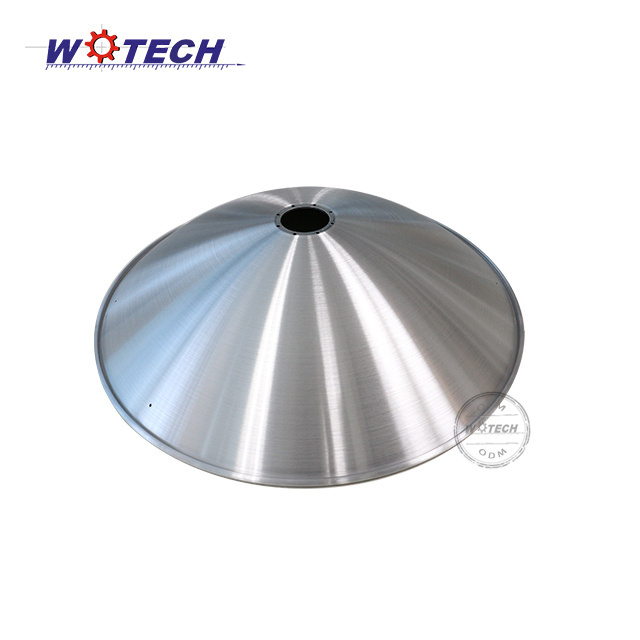

Spinning is to fix the flat plate or hollow blank on the mold of the spinning machine. While rotating the spindle of the random bed, press the blank with a rotating wheel or a rod to make local plastic deformation. Spinning can complete the complex geometric features of various complex sheet metal parts and is a special method of sheet metal forming. The geometric characteristics of complex sheet metal parts such as drawing, flanging, shrinking, bulging and crimping can be accomplished by spinning.

|

Product Name

|

Customized Metal Spinning Parts Fabricated Stainless Steel Cones

|

|

Material

|

Metal, Aluminium

|

|

Treatment

|

Brushed+Self Color Anodizing

|

|

Brand

|

WOTECH

|

|

Drawing

|

Available

|

|

Size

|

Diameter 80cm

|

|

Logo

|

Screen Printing

|

|

Used

|

building industry machinery

|

We paid all of our customers' annual visit to monitor our sales and services.

All of our components are produced and inspected according to national/international standards. We never ship out un-qualified parts to our customers. We strictly adhere to after-sales rules and regulations of national industry mechanical hardware products.

Upon written notice, we are able to ship replacement parts provided they can issue the third party inspection report to prove our product defects.

Value & Strategy

Value

Spinning Specialist Stable and Progressively improved quality On time delivery,

Perfect ODM&OEM Solution Innovation,

Flexibility, and a big 'S' for service Trustworthiness,

Safety and Reliability for Partners.

Strategy

We continuously innovate and conduct ourselves as a highly trustworthy specialized supplier.

We highly value the creative and hard work of all our team members.

We aim to become the most excellent specialized supplier in the field.

We aim to strive for satisfactory products in conform to QCDS. (Quality-Cost-Delivery-Services)

Quality Assurance

Product-Quality Preliminary Engineering (APQP) Production Processes Guarantee System (QA) Independent inspection and quality control aside from workshop's quality department (QC)

Core Competence

SMART

S: big S for Services

M: Mutual benefits for our partners

A: Ability of Flexibility and Innovation

R: Rapid Response and decision making

T: Teamwork Sprits

We can produce all kinds of mechanical parts and components based on technical drawing, sample, or a Concept.

Our Competitive advantages

One-Stop Shopping from "Drawing to Part".

More than 10 years' experience in domestic and overseas markets makes us a professional and efficient company in the industry. We have been keeping stable business relations for more than 5 to 10 years with our major clients in Europe and US market, and Asia.

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

Engineering Services: Conceptual design, Rapid Prototyping, R&D, FIMA, APQP, part production with PPAP, 3D model analysis, independent warehouse QC and QA and a traceable product data management to meet AQL requirement. All our operations are strictly compliant with ISO 9001: 2008 guidelines and VDA five quality management tools. PDM, MRP, automated investment casting lines, CNC machining, CMM inspection, along with spectrometers and MT testing equipment all contribute to precision, reliability and better QA. To further ensure the safety and quality of your order, we also boast a fully independent QC process.

Our Vision - To be a valuable supplier for customized engineered products and a global platform for cost effective solutions in manufacturing ODM & OEM products!

Packing Details : Outer: non-coniferous wooden plywood packages, inner: paper cartons+bubble bag

Delivery Details : within 30 days after down payment

All of our workshop has ISO or TS16949 certification. Timely equipment maintenance, Working Instruction for each part and strict QC system will offer you a perfect product.