- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2022

-

Weight (KG):

-

1350

-

Name:

-

automatic stirrup making machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Automatic

-

Application:

-

Construction Projects

-

Material:

-

steel wire, rebar

-

Bending diameter:

-

4-13mm

-

Trade Assurance product:

-

100% payment, quality, on time shipment protection

-

Color:

-

Red, Blue, Yellow etc

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Heng Yi Sheng

-

Marketing Type:

-

Hot Product 2022

-

Year:

-

2022

-

Weight (KG):

-

1350

-

Name:

-

automatic stirrup making machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Automatic

-

Application:

-

Construction Projects

-

Material:

-

steel wire, rebar

-

Bending diameter:

-

4-13mm

-

Trade Assurance product:

-

100% payment, quality, on time shipment protection

-

Color:

-

Red, Blue, Yellow etc

Products Description

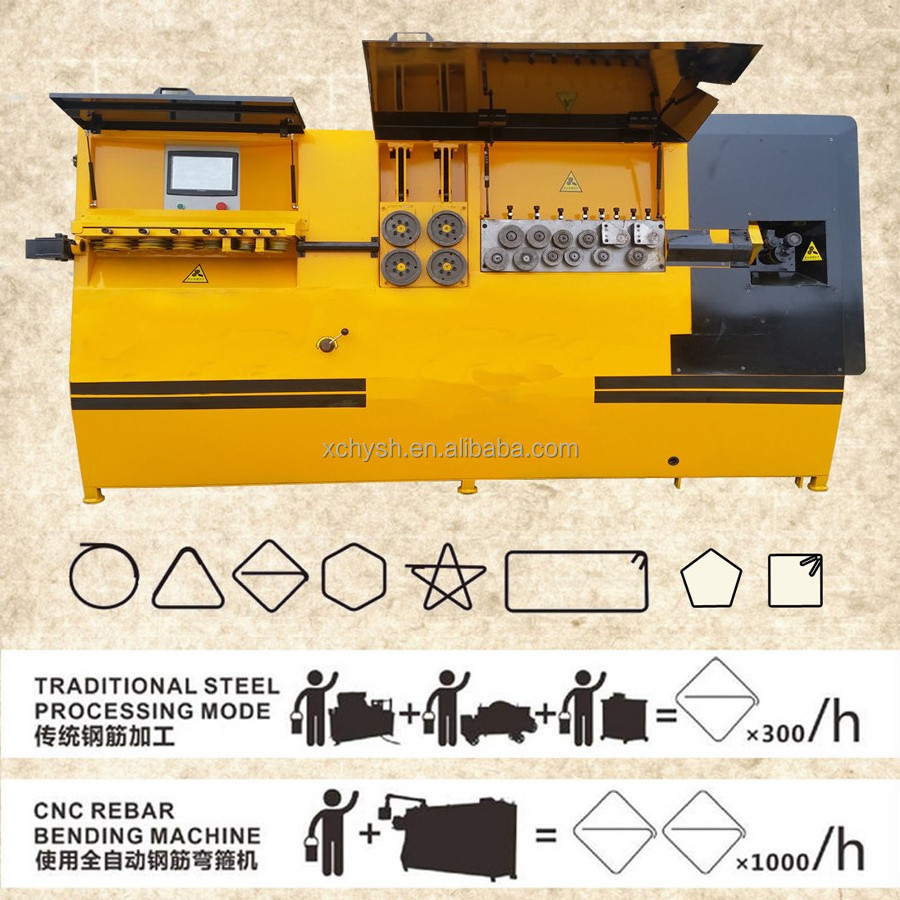

1. Introduction of

CNC rebar

bending machine

1) Frictional progressive feeding mechanism with high accuracy and no harm to steel bar rib.

2) The benders apply double line feeding system, which can greatly increase the productivity and reduce the labor intensity.

3) With the function of quick back and forth bending, the double vane bending die has improved its bending performance.

4) Powerful hydraulic shearing mechanism with good reliability.

5) The powerful memory database provides hundreds of shapes for using.

6) Quick-adjusting system has the function of machine diameter.

7) Bending scope of coiled steel bar ranges from 4mm to 16mm.

8)Synchronous belt drive with high accuracy and low cost of maintenance.

9)Hydraulic Controlling system.

1) Frictional progressive feeding mechanism with high accuracy and no harm to steel bar rib.

2) The benders apply double line feeding system, which can greatly increase the productivity and reduce the labor intensity.

3) With the function of quick back and forth bending, the double vane bending die has improved its bending performance.

4) Powerful hydraulic shearing mechanism with good reliability.

5) The powerful memory database provides hundreds of shapes for using.

6) Quick-adjusting system has the function of machine diameter.

7) Bending scope of coiled steel bar ranges from 4mm to 16mm.

8)Synchronous belt drive with high accuracy and low cost of maintenance.

9)Hydraulic Controlling system.

2. Features of CNC rebar bending machine

1) CNC rebar bending machine:adopt servo controlling system.

2) Automatically accomplish the functions of rebar's feeding, straighten, bending and cutting etc.

3) CNC rebar bending machine: MAX bending diameter of rebar is 16mm.

4) Continuously bend various stirrup of plane figure.

5) Widely used in construction industry and rebar manufacturing enterprise.

6) High efficiency and accurate processing precision.

1) CNC rebar bending machine:adopt servo controlling system.

2) Automatically accomplish the functions of rebar's feeding, straighten, bending and cutting etc.

3) CNC rebar bending machine: MAX bending diameter of rebar is 16mm.

4) Continuously bend various stirrup of plane figure.

5) Widely used in construction industry and rebar manufacturing enterprise.

6) High efficiency and accurate processing precision.

3. Parameters of CNC rebar bending machine

|

Model No.

|

|

HYS-

Develop

NO.1

|

HYS-Develop

NO.2

|

HYS-Develop

NO.3

|

HYS-Develop NO.4

|

HYS-

Develop NO.5

|

HYS-

Develop

NO.6

|

|

|

Single Line Working Capacity

|

Round steel bar

|

4-10mm

|

4-12mm

|

5-14mm

|

4-12mm

|

5-14mm

|

5-16mm

|

|

|

|

Ⅲ grade deformed steel bar

|

4-8mm

|

4-10mm

|

5-14mm

|

4-10mm

|

5-14mm

|

5-16mm

|

|

|

|

Round steel bar

|

4-6mm

|

4-10mm

|

5-10mm

|

4-10mm

|

5-10mm

|

5-13mm

|

|

|

|

Ⅲ grade deformed steel bar

|

4-6mm

|

4-8mm

|

5-10mm

|

4-8mm

|

5-10mm

|

5-13mm

|

|

|

Max. bending angle

|

|

180°(Single direction)

|

180°(Single direction)

|

±180°(double direction)

|

±180°(double direction)

|

±180°(double direction)

|

±180°(double direction)

|

|

|

Max. feeding speed

|

|

4800m/h

|

4800m/h

|

6000m/h

|

4800m/h

|

6000m/h

|

6000m/h

|

|

|

Max. bending speed

|

|

8000°/s

|

1000°/s

|

1200°/s

|

1000°/s

|

1200°/s

|

1200°/s

|

|

|

Length Error

|

|

±1mm

|

±1mm

|

±1mm

|

±1mm

|

±1mm

|

±1mm

|

|

|

Angle Error

|

|

±1°

|

±1°

|

±1°

|

±1°

|

±1°

|

±1°

|

|

|

Average power consumption

|

|

4.5kw/h

|

5kw/h

|

5kw/h

|

5kw/h

|

5kw/h

|

5kw/h

|

|

|

Motors power

|

|

16.9kw

|

18.9kw

|

36.6kw

|

22.8kw

|

36.6kw

|

53.5kw

|

|

|

L*W*H

|

|

2600x880x1700mm

|

3280x1000x1700mm

|

3560x1080x2030mm

|

3280x1000x1700mm

|

3560x1080x2030mm

|

4000*2000*2200mm

|

|

|

Weight

|

|

1150kg

|

1350kg

|

2200kg

|

1350kg

|

2450kg

|

2600kg

|

|

Product Pictures

Main

components

Develop

series products

Packing&Delivery pictures

Customers' Feedback

Related Products

Sales and service network

FAQ

1. What's your payment method?

Payment: 40% T/T in advance and balance 60% after inspection confirmation before shipment.

Payment: 40% T/T in advance and balance 60% after inspection confirmation before shipment.

2.What is the delivery time?

The deliver time is within 7 days after receiving the deposit.

The deliver time is within 7 days after receiving the deposit.

3. What services do you provide?

We provide our customers with 1 year warranty and technical support is provided for free.

We provide our customers with 1 year warranty and technical support is provided for free.

4. How to get to your factory?

You can fly to Zhengzhou airport, Henan province, we will arrange to pick you up.

5.Any other need to inquiry, welcome here.

You can fly to Zhengzhou airport, Henan province, we will arrange to pick you up.

5.Any other need to inquiry, welcome here.

Our services

1. Help you choose the most suitable machine.

2. Customize the machine according to your request.

3. Give you machine’s details and video for help you use the machine more better.

4. We offer full set of spare parts and tools for convenient use.

5. We can send our engineer abroad to training customers to operate the machine.

6. Normally any problem can be resolved online together with our customers. If necessary, We can send our engineer over sea.

2. Customize the machine according to your request.

3. Give you machine’s details and video for help you use the machine more better.

4. We offer full set of spare parts and tools for convenient use.

5. We can send our engineer abroad to training customers to operate the machine.

6. Normally any problem can be resolved online together with our customers. If necessary, We can send our engineer over sea.

Hot Searches