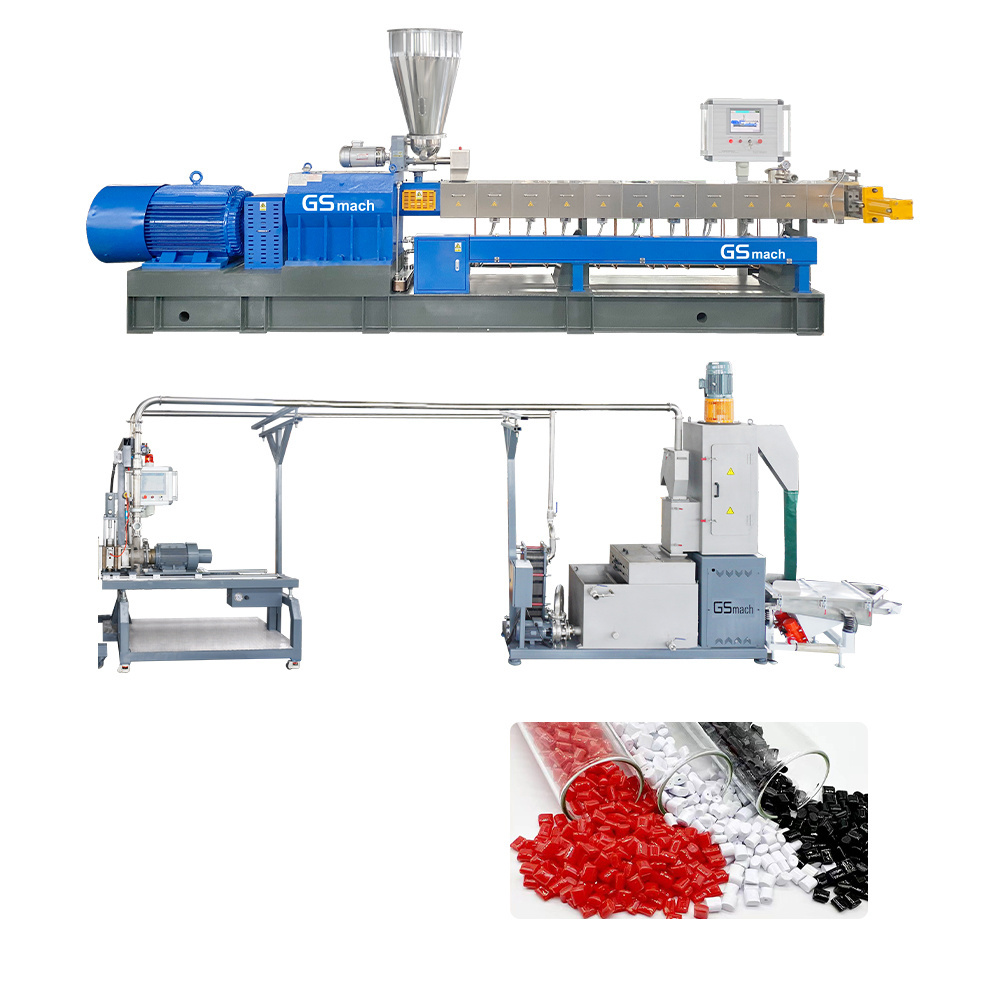

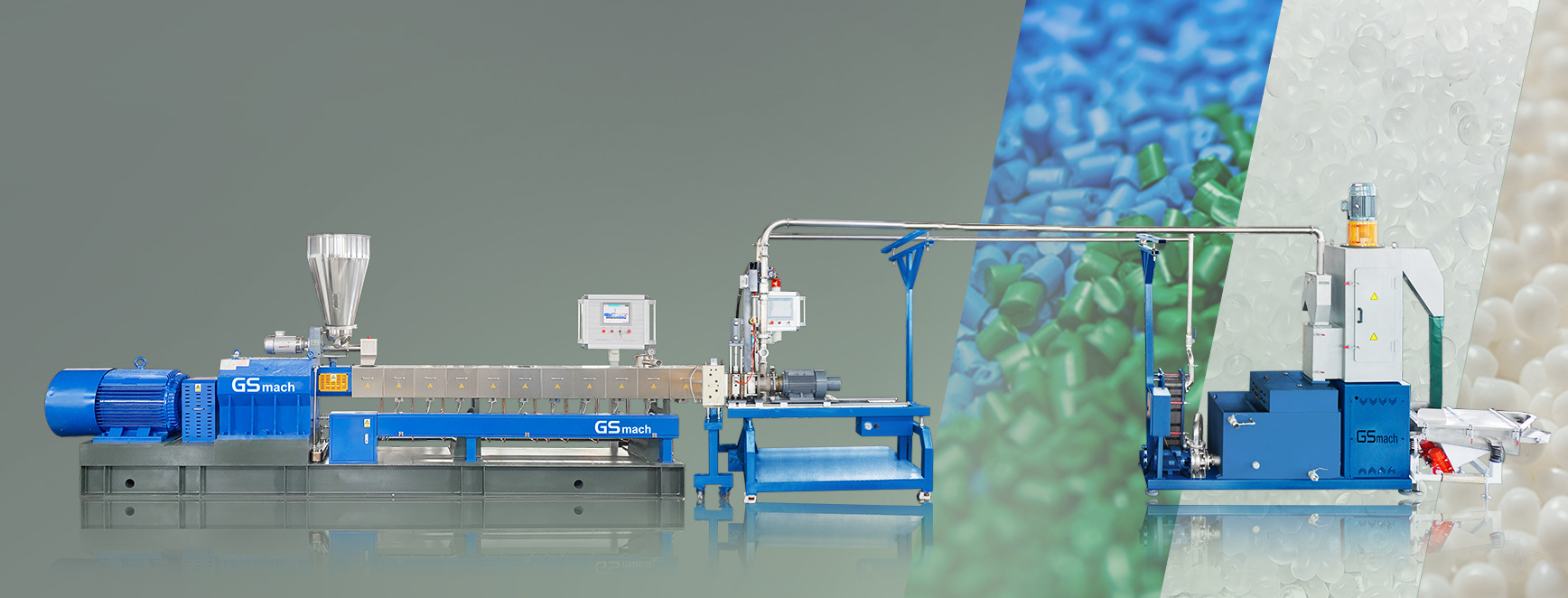

Nanjing GS-mach Extrusion Equipment Co.,Ltd

No.12 Shanghu Industrial Park,Jiangning Street, Jiangning District,Nanjing China

Mobile Phone: +86 18151606635

Whatsapp/ wechat: +86 18151606635

Email: sales6@njgsmach.com

Whatsapp/ wechat: +86 18151606635

Email: sales6@njgsmach.com