1.High Speed Feeder, 4 suckers for lifting and 4 suckers for conveying structure. Max Speed 12000 sheets/h

2. The paper feeding table has upper and lower over-limit protection

3. Double or multi-sheet detection device

4. The paper pile table rise protection device, there is a micro switch above the paper carrier to prevent the paper from rising too

high and hitting the feeder

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JIALITE

-

Dimension(L*W*H):

-

6648*1735*1920mm

-

Weight:

-

4850 KG

-

Max Paper Size:

-

780*1050mm

-

Min Paper Size:

-

260*210mm

-

Speed:

-

5-80m/min

-

Overlap Precision:

-

≤±2mm

-

Film Thickness:

-

12/15 micrometer

-

Non-Stop Feeding Height:

-

1300mm

-

Collector Paper Height(incl. pallet):

-

1300mm

-

Working power:

-

18kw

-

Main motor power:

-

5.5kw

-

Max Film Roll Diameter:

-

400mm

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Plastic, Metal

-

Driven Type:

-

Mechanical

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JIALITE

-

Dimension(L*W*H):

-

6648*1735*1920mm

-

Weight:

-

4850 KG

-

Max Paper Size:

-

780*1050mm

-

Min Paper Size:

-

260*210mm

-

Speed:

-

5-80m/min

-

Overlap Precision:

-

≤±2mm

-

Film Thickness:

-

12/15 micrometer

-

Non-Stop Feeding Height:

-

1300mm

-

Collector Paper Height(incl. pallet):

-

1300mm

-

Working power:

-

18kw

-

Main motor power:

-

5.5kw

-

Max Film Roll Diameter:

-

400mm

Product Apperance

Products Description

NFY-Aseries laminating machine is an economical pre-coating type laminating machine specially designed for small paper. as a professional equipment used for plastic film laminating on the surface of paper, Widely applicable for laminating in advertising poster, Picture books and magazine, display book, color paper box, calendars, and commercial cards fields, Improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof.

Thermal laminating (Pre-coating /thermal film)

Thermal laminating (Pre-coating /thermal film)

Film: OPP, BOPP, SOFT TOUCH FILM.

Specifications for

NFY-A800*1050 Automatic Paper Thermal Laminator High Speed Pre-coting BOPP OPP Film Laminating Machine

|

Model

|

NFY-A800*1050

|

|

Max Paper Size

|

780*1050mm

|

|

Min Paper Size

|

260*210mm

|

|

Speed

|

5-80m/min

|

|

Paper Thickness (Round Knife)

|

105-500gsm

|

|

Overlap Precision

|

≤±2mm

|

|

Film Thickness

|

12/15 micrometer

|

|

Non-Stop Feeding Height

|

1000mm

|

|

Collector Paper Height(incl. pallet)

|

1000mm

|

|

Main motor power

|

5.5kw

|

|

Working power

|

18kw

|

|

Power

|

380V-50Hz-3P

|

|

Installed Power

|

40 KVA

|

|

Weight

|

4850kgs

|

|

Dimension (layout)

|

6648*1735*1920mm

|

|

Loading

|

20HQ

|

Details Images

FEEDING UNIT

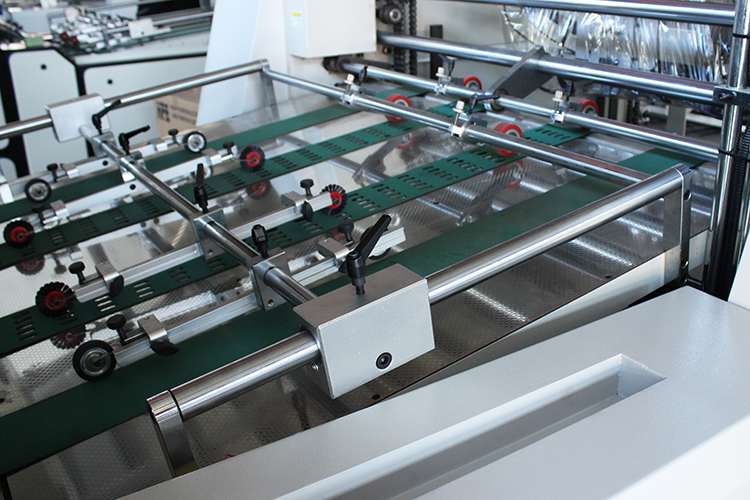

CONVEYING TABLE

1.The conveying table adopts customized stainless steel corrugated board

2.The brush wheel and rubber pressing wheel move smoothly

3.Servo motor overlap, improve accuracy of lap, error≤±2mm

2.The brush wheel and rubber pressing wheel move smoothly

3.Servo motor overlap, improve accuracy of lap, error≤±2mm

LAMINATOR HOST

1.The steel hot-press steel roller (Dia.380mm) adopts electromagnetic heating system, electromagnetic heating cover is installed on

the top of the steel roll, Rapid heating, energy saving and environmental protection.

2.The pressing pressure is controlled by two sets of hydraulic cylinders and an automatic hydraulic system, which can balance the

pressure on the upper and lower rollers

3.The surface of the pressure roller is covered with a special strength rubber layer.

4.Touch screen control board, The Internet of things, long remote control.

the top of the steel roll, Rapid heating, energy saving and environmental protection.

2.The pressing pressure is controlled by two sets of hydraulic cylinders and an automatic hydraulic system, which can balance the

pressure on the upper and lower rollers

3.The surface of the pressure roller is covered with a special strength rubber layer.

4.Touch screen control board, The Internet of things, long remote control.

DISC KNIFE CUTTING

1.Cutting part with round (fly) knife device, easy adjustment. It can make sure effective cutting for paper more than 105g/m². Round blade for OPP, BOPP and PVC film, round blade matching Skip roller make cutting quick and clear.

2.Cutter with the anti-roll device, it could be appropriate to improve the curl phenomenon when the thin paper to be

pull-breaking.

3.The cutter adopts variable frequency speed control which could able to synchronize with the laminator unit part.

4.The bounce device ensures rapid film breaking

5.PLC programmable special module linkage system, automatically increase or decrease according to the speed of the laminating host.

2.Cutter with the anti-roll device, it could be appropriate to improve the curl phenomenon when the thin paper to be

pull-breaking.

3.The cutter adopts variable frequency speed control which could able to synchronize with the laminator unit part.

4.The bounce device ensures rapid film breaking

5.PLC programmable special module linkage system, automatically increase or decrease according to the speed of the laminating host.

COLLECTOR UNIT

1.Wave-type paper delivery mechanism, conducive to thin paper collection

2.Blowing device is conducive to tissue collection

3.Front and right paper patting device; paper delivery is neat and clean

2.Blowing device is conducive to tissue collection

3.Front and right paper patting device; paper delivery is neat and clean

Hot Searches

![[JT-SW820]CE Standard Automatic Thermal Film Laminator Machine Hot Melt Film Laminator Pe Film Lamination Wallpaper Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/a14d6c28441a3b6f8383dbbb53a1eea6.jpg!/rotate/180/sq/300)