- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

GD prototyping66

-

Brand Name:

-

GD prototyping

-

Material:

-

plastic

-

Surface treatment:

-

Plating

-

Service:

-

Customized OEM CNC Machining

-

OEM/ODM:

-

OEM ODM Non-standard Processing

-

Processing Type:

-

5 Axis CNC Machining

-

Name:

-

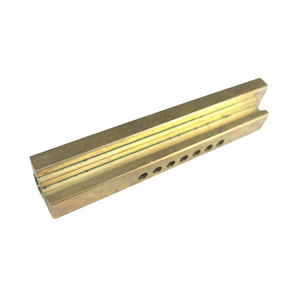

auto parts light guide strip five-axis cnc machining

-

Keyword:

-

Transparent plastic light guide strip machining

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

GD prototyping66

-

Brand Name:

-

GD prototyping

-

Material:

-

plastic

-

Surface treatment:

-

Plating

-

Service:

-

Customized OEM CNC Machining

-

OEM/ODM:

-

OEM ODM Non-standard Processing

-

Processing Type:

-

5 Axis CNC Machining

-

Name:

-

auto parts light guide strip five-axis cnc machining

-

Keyword:

-

Transparent plastic light guide strip machining

Auto lamp cnc machining transparent acrylic auto parts light guide strip five-axis cnc machining

GD prototyping,Focus on the production of prototype models in the automotive industry,From exterior optical lighting to interior component,We Are Experienced In Automotive Prototyping And Auto Parts Manufacturing.

Automotive Lighting Lamps - Optical Component Prototypes

Auto Lamp Lens – Machining Acrylic and Clear Polishing

Machining experience of thin-walled clear plastic

Unparalleled hand finishing and polishing technology

Advanced two-color and multi-material (2K) molding process

Light Guides and Aluminium Reflectors – Precision Optical Machining

Combine 5-axis precision milling with diamond machining technology

More complex geometric shapes and precise optical details can be achieved

Minimum machining radius R0.1mm and surface tolerance ±0.02mm

CNC milled roughness Ra(μm) 0.2 and mirror-polished Ra(μm) 0.05

GD prototyping, our focus is on provide you the best services in rapid prototyping, rapid tooling and low-volume manufacturing. Our international team of engineers and technicians are dedicated to making your custom parts using the most advanced equipment and techniques including 3D printing, SLA/SLS, Vacuum casting, Metal sheet and 5-axis CNC machining. We're here to turn your ideas into reality quickly.

| Our Service | Prototypes manufacturing ,CNC Machining,Vacuum casying,3D Printing,Metal Sheet,Molding,Plastic Injection |

| Our Advantages | High Efficiency: More than 60 professional masters operating over 100 machining equipments 24h one day, to promise the production lead time within 1~7 days |

| Quality:Material inspection Guarantee,Tightest Tolerance up to 0.005mm,Maxmum Machining Length: 2100mm,High precision inspection equipments assure product meet each customer's request. | |

| Services:Sign NDA before cooperate,Quoting within one day, Visable machining processing, whole production QC inspection ,Free remake if our quality issue | |

| Price:GD prototyoing provide high quality product with a lower price. | |

| Application | Automative part,Robot,Lighting,Mechanical Hardware,Aerospace&military,Electronic Device,Medical Equipment,Digital Appliance,Automobile,Intelligent Safeguard Systems,UAV |

| Processing | CNC Machining:3axis/4axis/5axis CNC Machining center,CNC Lathe Machining,Milling&turning machining, Wire Cutting, EDM, Grinding |

| 3D Printing:SLA,SLS,SLM,MJF,DLP | |

| Vaccum Casting | |

| Sheet Metal:Lasering Cutting, Bending, Welding, Riveting | |

| Molding Injection : Encapsulates Moulds, Insert Injection Molding, Monochrome Injection Molding, Overmold | |

| Processing Flow | Order confirmation→Programming→CNC Machining→Post-processing→Product Inspection→Packing and Delivery |

| Machining Equipment | 3 axis&4 axis&5 axis CNC Machining Center,High-speed Engraving and Milling Machines,,Drilling and Tapping Machines,CNC Lathes,Industrial 3D Printers,plastic Injection Machines |

| Machining Capicity | 10000pcs per day |

| Drawing Format | STEP,STP,PRT,IGS,XT,STL |

| Machining Material | Plastic:ABS,PC,PE,POM,PP,PMMA,Nylon, Bakelite, Silicone/ Rubber, PP, PA, PVC, PEEK |

| Metal:Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Titanium Alloy, Stainless Steel, Sheet Metal, Steel, Copper, Iron, | |

| Surface Treatment | Anodize,Electroplating,Sand Blast,Baking,oil Painting,Powder Coating,Polish,Silk-screen,Brushing ,Blacking,Laser Marking,Laser Engraving,Surface Etching,Overmoding,PVD,Helicoil,Insert |

| Quality Control | 1.Material Inspection 2.Dimension Inspection 3.Visual Inspection 4.Functional Inspection 5.Structual Inspection 6.Surface Treatment Inspection 7.Package Inspection |

| Inspection Equipment | CMM, 2.0 CMM, Inner Diameter Micrometer, Outer Diameter Micrometer, Electronic Height Gauge, Hardness Meter, Thread go-no-go Gauge, Thread Ring Gauge, Electronic Caliper, |

| Inspection Flow | Material Purchase→ Material inspection→Storage→Material Preparing→CNC Machining→Assembling and checking→Surface treatment →QC Final Inspection→ Packaging→Delivery |

| Lead time | 1-10days |

| Package | Inside package:Plastic Bubble Wrap; Outside package:Outer carton or Custom Wooden Box |

| Cooperation Flow | Design providing→Quotation→Ordering→Production process→Surface Treatment→Quality Inspection→Packing and delivery→Confirm Receipt→After-sale Service |

| Payment Terms | T/T,Paypal |

|

50% deposit and balance 50% paid before shipment. |

|

| Shipment | Express Delivery, Ocean, Truck, Railway |

GD prototyping technology(HK) Ltd was established in 2010, located in Chang’an town, Dongguan, Guangdong, China. Which is a prototype and low-volume manufacturer with more than 10 years experiences in producing automotive, aerospace industries, IT and digital products, Telecommunication, home appliances, medical equipment and other industries.

The company covers an area of more than 8000 square meters and has more than 200 permanent staff, our products are exported to Europe, America, Asia Pacific, Middle East and other regions. Among them, Continental, HELLA and Mitsubishi and other international famous brands have established a long-term cooperative relations with us and we had also win them a high reputation.

At GD prototyping, our focus is on provide you the best services in rapid prototyping, rapid tooling and low-volume manufacturing. Our international team of engineers and technicians are dedicated to making your custom parts using the most advanced equipment and techniques including 3D printing, SLA/SLS, Vacuum casting, Metal sheet and 5-axis CNC machining. We’re here to turn your ideas into reality quickly, accurately and at a great price.

C ore advantages:

1.8000 square meter workshop

2. 100 CNC machines

3. 200 experienced worker

4.98% on time delivery

5.Strict QC process and fully inspection euipment, especially CMM

6.13 years professional manufacturer

7. 98 % pass rate

Q: Are you trading company or manufacturer ?

A: We are a fully experienced manufacturer for over 13 years.

Q: How to get a quotation?

A: Please send us drawings in igs, dwg, step format etc, with detailed PDF.If you have any

requirements, please share together, and then we will give out our offer and advisement.

Q. What if we do not have drawing?

A: Samples is available, and also we can provide 3d design service; Of course, we would ensure the safety of the drawing.

Q: How long is your delivery time?

A: It would be 5-12 days normally, and we had a production system to ensure punctual delivery.

Q:How to ship? What about the packing details?

A: For small quantity, we have cooperation with DHL, FEDEX express.For big quantity, air or sea would be available for you to choose.If you have any special requirements, we would be willing to help.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the samples at an extra charge, as we don't have MOQ.

Q: What is your terms of payment ?How to pay?

A: 50% T/T in advance ,balance before shippment

The above prices are for reference only.If you need to know more, please feel free to contact us, thank you!