- Product Details

- {{item.text}}

Quick Details

-

Drive Motor:

-

220v60w-220v370w

-

Water Inlet:

-

63-250mm

-

Demension:

-

96*65*70mm

-

Tank:

-

Brand new PP

-

Filtration Accuracy:

-

200 mesh

-

Weight:

-

50-230kg

-

Swage Draining Exit:

-

50-63mm

-

Water Outlet:

-

110mm-250mm

-

Place of Origin:

-

CN;JIA

Quick Details

-

Brand Name:

-

Holly

-

capacity:

-

10-200m3/h

-

Material:

-

SS610L/SS304

-

Drive Motor:

-

220v60w-220v370w

-

Water Inlet:

-

63-250mm

-

Demension:

-

96*65*70mm

-

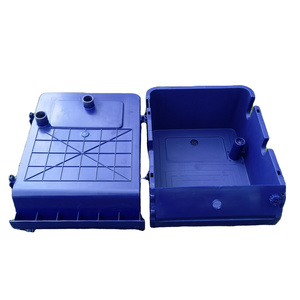

Tank:

-

Brand new PP

-

Filtration Accuracy:

-

200 mesh

-

Weight:

-

50-230kg

-

Swage Draining Exit:

-

50-63mm

-

Water Outlet:

-

110mm-250mm

-

Place of Origin:

-

CN;JIA

Products Description

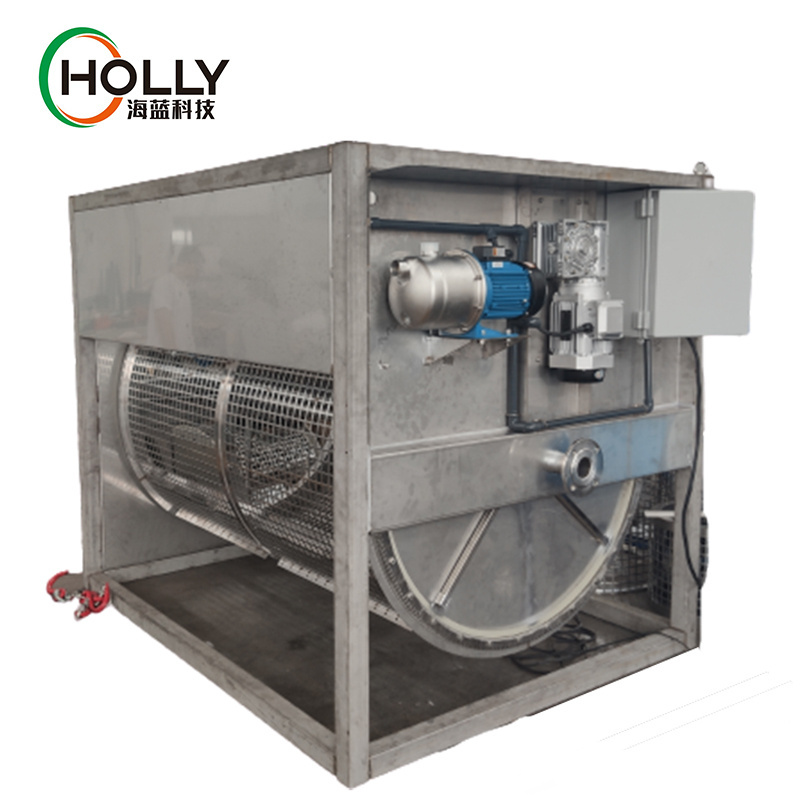

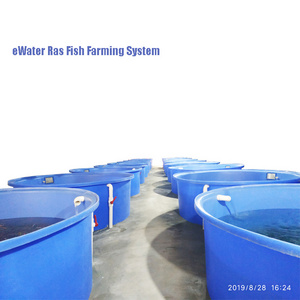

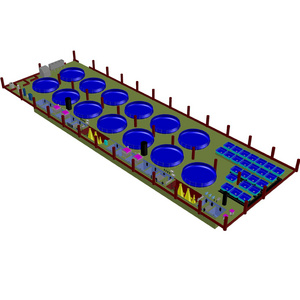

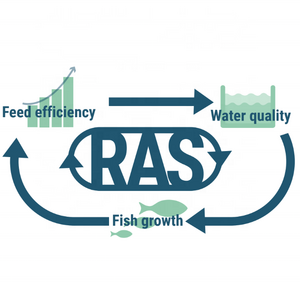

Recirculating Aquaculture System RAS Fish Shrimp Farming Aquaculture Indoor Farm

Drum filter (also known as drum micro filtration screen) is a solid-liquid separation equipment, widely used in the first stage of raw water or sewage solid-liquid separation process in aquaculture, waterworks, urban domestic sewage, papermaking, textile, printing and dyeing, chemical industry, etc.

It is mainly composed of four parts: tank component, roller component, backwash component and liquid level automatic control component. The roller component consists of a roller frame (which can be made of metal or plastic) and a screen (stainless steel screen or nylon screen). The main function is to filter tiny suspended substances in the water (fish excrement, bait, pulp fiber, sand), Plankton such as algae and daphnia.

Applications

1. Factory indoor aquaculture farms, especially high-density aquaculture farms.

2. Aquaculture nursery ground and ornamental fish culture base;

3. Seafood temporary maintenance and transportation;

4. Water treatment of aquarium project, seafood fish pond project, aquarium project and aquarium project.

2. Aquaculture nursery ground and ornamental fish culture base;

3. Seafood temporary maintenance and transportation;

4. Water treatment of aquarium project, seafood fish pond project, aquarium project and aquarium project.

Technical parameters

Box Type Drum Filter

The drum filter is mainly composed of four parts: tank component, roller component, backwash component and liquid level automatic control component. It is made of non-toxic seawater corrosion-resistant high-quality engineering plastic materials. A stainless steel filter screen is fixed on the rotatable drum, and the tiny suspended substances in the water are

separated and filtered through the screen and finally achieve solid-liquid separation. During the filtering process, small

suspended particles in the water will cause the screen to be blocked. When the screen is blocked, the liquid level automatic control component works, and the backwash water pump and roller reducer automatically start working to make the screen timely cleaning to keep the equipment in good working condition.

separated and filtered through the screen and finally achieve solid-liquid separation. During the filtering process, small

suspended particles in the water will cause the screen to be blocked. When the screen is blocked, the liquid level automatic control component works, and the backwash water pump and roller reducer automatically start working to make the screen timely cleaning to keep the equipment in good working condition.

|

|

Capacity

|

Dimension

|

Drive

Motor

|

Backwash

Pump

|

Water

Inlet

|

Sewage draining

exit

|

Water

Outlet

|

Weight

|

|

1

|

10m3/h

|

95*65*70

cm

|

220v 120w

|

SS304

220v 370w

|

63mm

|

50mm

|

110mm

|

40kg

|

|

2

|

20m3/h

|

100*85*83

cm

|

220v 180w

|

SS304

220v 370w

|

110mm

|

63mm

|

110mm

|

55kg

|

|

3

|

30m3/h

|

100*95*95

cm

|

220v 180w

|

SS304

220v 370w

|

110mm

|

63mm

|

110mm

|

75kg

|

|

4

|

50m3/h

|

120*100*

100cm

|

220v 300w

|

SS304

220v 370w

|

160mm

|

63mm

|

160mm

|

105kg

|

|

5

|

100m3/h

|

145*105*

110cm

|

220v 300w

|

SS304

220v 370w

|

160mm

|

63mm

|

200mm

|

130kg

|

|

6

|

150m3/h

|

165*115*

130cm

|

220v 370w

|

SS304

220v 550w

|

200mm

|

63mm

|

250mm

|

185kg

|

|

7

|

200m3/h

|

180*120*

140cm

|

220v 370w

|

SS304

220v 550w

|

200mm

|

63mm

|

250mm

|

230kg

|

Submersible Drum Filter

The open drum filter is mainly composed of three parts: roller component, backwash component and electric control box system.

A stainless steel filter screen is fixed on the rotatable drum, and the tiny suspended substances in the water are separated and filtered through the screen and finally achieve solid-liquid separation.

During the filtering process, small suspended particles in the water will cause the screen to be blocked. When the screen is blocked, the liquid level automatic control component works, and the backwash water pump and roller reducer automatically start working to make the screen timely cleaning to keep the equipment in good working condition.

A stainless steel filter screen is fixed on the rotatable drum, and the tiny suspended substances in the water are separated and filtered through the screen and finally achieve solid-liquid separation.

During the filtering process, small suspended particles in the water will cause the screen to be blocked. When the screen is blocked, the liquid level automatic control component works, and the backwash water pump and roller reducer automatically start working to make the screen timely cleaning to keep the equipment in good working condition.

|

|

Capacity

|

Dimension

|

Drive

Motor

|

Backwash Pump

|

Control

|

Inlet

|

sewage draining exit

|

Weight

|

|

1

|

10m3/h

|

65*45*55cm

|

220v 60w

|

220v 180w

|

Intelligent Water Level Control

Or Timing Control |

110

mm

|

63mm

|

35kg

|

|

2

|

20m3/h

|

75*60*70cm

|

220v 60w

|

SS304

220v 370w

|

110mm

|

160

mm

|

110mm

|

47kg

|

|

3

|

30m3/h

|

75*70*85cm

|

220v 60w

|

SS304

220v 370w

|

110mm

|

160

mm

|

110mm

|

59kg

|

|

4

|

50m3/h

|

95*70*85cm

|

220v 90w

|

SS304

220v 370w

|

160mm

|

160

mm

|

160mm

|

67kg

|

|

5

|

100

m3/h

|

120*75*90cm

|

220v 90w

|

SS304

220v 370w

|

160mm

|

200

mm

|

200mm

|

82kg

|

|

6

|

150

m3/h

|

145*95*105cm

|

220v 90w

|

SS304

220v 550w

|

200mm

|

200/250mm

|

250mm

|

110kg

|

Features

1. Durable, safe and energy saving .

2. Replacing the water pressure requirements of the sand tank, it is energy-saving, non-blocking, and can run continuously, effectively filtering impurities in the water. Various sizes can be customized.

2. Replacing the water pressure requirements of the sand tank, it is energy-saving, non-blocking, and can run continuously, effectively filtering impurities in the water. Various sizes can be customized.

3.

Our company's drum filter is designed for the problems that the existing filters cannot work automatically, is not resistant to corrosion, the screen is easy to break, easy to block, equipment failure rate is high, and maintenance and operation are difficult. It is one of the solid-liquid separation technologies in the early stage of water treatment in the aquaculture system. This product purifies the water by separating the solid waste in the aquaculture water to achieve the purpose of recycling.

Working Principle

When the water containing tiny suspended substances enters the roller, the tiny suspended substances are intercepted by the stainless steel screen, and after filtering, the water without suspended substances enters the reservoir.

When the suspended substances in the roller accumulates to a certain amount, it will cause the water permeability of the screen to decrease, causing the water level in the roller to rise.

When the suspended substances in the roller accumulates to a certain amount, it will cause the water permeability of the screen to decrease, causing the water level in the roller to rise.

When the suspended substances in the roller accumulates to a certain amount, it will cause the water permeability of the screen to decrease, causing the water level in the roller to rise.

When the water level rises to the set high water level, the liquid level automatic control component works. At this time, the

backwash water pump and the roller reducer automatically start working at the same time. The high-pressure water of the backwash water pump is subjected to high-pressure cleaning of the rotating screen. After washing,suspended substances

flows into the dirt collection tank and is discharged through the sewage pipe.

When the water level rises to the set high water level, the liquid level automatic control component works. At this time, the

backwash water pump and the roller reducer automatically start working at the same time. The high-pressure water of the backwash water pump is subjected to high-pressure cleaning of the rotating screen. After washing,suspended substances

flows into the dirt collection tank and is discharged through the sewage pipe.

After the screen is cleaned, the water permeability of the screen rises and the water level drops. When the water level drops to the set low water level, the backwash water pump and the roller reducer will automatically stop working, and the filter will enter a new a working cycle

Certifications

Hot Searches