- Product Details

- {{item.text}}

Quick Details

-

After Warranty Service:

-

Online support

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LIVTER

-

Weight (KG):

-

2

-

After Warranty Service:

-

Online support

We need to customize according to your blade, charged according to the material by weight, weight = length * width * height * 8. Different material, the material of the blade have common spring steel, 55 sicr, SKD11, D2, DC53.

|

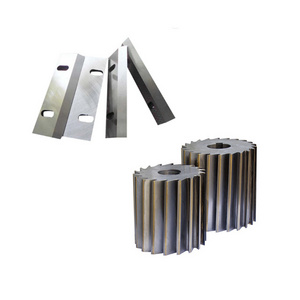

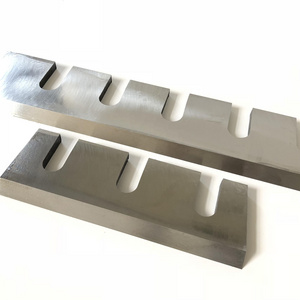

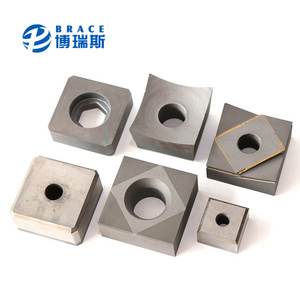

Our shredder blades are high-quality blades designed specifically for plastic branch crushers. We offer customization capabilities to design and manufacture blades based on customer requirements and machine specifications.

Firstly, our shredder blades are made with premium materials, ensuring excellent wear resistance and durability. The blades are professionally designed to efficiently crush plastic branches into the desired particle size, enhancing crushing efficiency. Secondly, we provide a variety of different shapes and sizes of shredder blades to accommodate different models and specifications of shredders. We can customize blades according to customer machine requirements, ensuring perfect fit and optimal crushing performance. Furthermore, our shredder blades are competitively priced, offering good value for money. We provide competitive pricing while guaranteeing the quality and performance of the blades. Our shredder blades can be widely used in plastic recycling, waste management, plastic processing, and other industries. They effectively crush various plastic branches, transforming them into reusable particles, facilitating efficient resource utilization. In summary, our shredder blades have customization capabilities to design and manufacture blades based on customer requirements and machine specifications. They offer high wear resistance, high crushing efficiency, and reasonable pricing. They can be widely used in plastic branch crushers, helping customers achieve efficient and environmentally friendly plastic crushing processing. |

|

Type

|

Specification

|

Power

|

Speed

|

No.of blade

|

Intel size

|

|

|

|

KW

|

r/min

|

|

mm

|

|

MY-500

|

φ200*10

|

7.5KW

|

16-24

|

40

|

500*420

|

|

|

φ200*20

|

7.5KW

|

|

20

|

500*470

|

|

MY-600

|

φ200*10

|

15KW

|

18-25

|

48

|

620*470

|

|

|

φ200*20

|

15KW

|

|

24

|

620*560

|

|

MY-800

|

φ200*20

|

15KW*2

|

18-25

|

32

|

820*470

|

|

|

φ200*30

|

30KW*2

|

|

18

|

790*670

|

|

MY-1000

|

φ300*25

|

30KW*2

|

18-25

|

32

|

980*560

|

|

|

φ300*30

|

30KW*2

|

|

27

|

980*750

|

|

|

φ300*40

|

45KW*2

|

|

20

|

1010*840

|

|

MY-1200

|

φ400*30

|

55KW*2

|

18-25

|

38

|

1190*840

|

|

|

φ400*40

|

55KW*2

|

|

28

|

1220*920

|

|

MY-1500

|

φ400*30

|

75KW*2

|

18-25

|

48

|

1520*750

|

|

|

φ400*40

|

75KW*2

|

|

36

|

1520*920

|

|

|

φ400*50

|

75KW*2

|

|

28

|

1520*1000

|

|

MY-2000

|

φ530*50

|

90KW*2

|

18-30

|

38

|

1980*1220

|

|

|

φ600*60

|

90KW*2

|

|

31

|

2020*1450

|

Note: The above is a reference value. The specific situation depends on the material to be processed, and the processing capacity will be different for different materials. We will design a suitable model according to your needs. Excellent material The company has medium carbon steel, high carbon steel, alloy steel, tool steel, high speed steel, tungsten steel for customer demand in terms of material selection. Carefully manufactured All kinds of CNC processing machinery and precision processing equipment are used to ensure the accuracy of the product High temperature quenching After repeated forging at high temperature for many times, the hardness is higher, the toughness is excellent, and the service life is longer. Quality inspection The quality of the knives is invisible to the naked eye. The inspection of the knives is an important task. The company has purchased inspection equipment and strictly inspected, and the products can be delivered only when they are qualified. Double shaft shredder blade Double shaft shredder blade is one of the important parts of the shredder. The quality and correct installation of the blade largely determine the use effect and life of the shredder. Generally, the spiral mounting method is adopted, and the spacer sleeve is separated in the middle. The thickness of the blade should be 0.2 to 0.3 thick to prevent the blade from colliding during operation and choose

a reasonable thickness and number of teeth according to the size of the product. With the development and innovation of the blade industry, the quality of the raw materials of the blade is increasing. The shredder blades are commonly used in a variety of materials, and the materials are generally selected according to different processing objects: Common materials used in the plastic industry are 42CrMo, W5SiCr, SKD-11; Common materials used in the metal industry are: 6CrW2Si, Cr12Mov, LD, H13; Common materials used in the wood industry are: 5WSiCr, 6CrW2Si, SKH, SKD-11, D2;

a reasonable thickness and number of teeth according to the size of the product. With the development and innovation of the blade industry, the quality of the raw materials of the blade is increasing. The shredder blades are commonly used in a variety of materials, and the materials are generally selected according to different processing objects: Common materials used in the plastic industry are 42CrMo, W5SiCr, SKD-11; Common materials used in the metal industry are: 6CrW2Si, Cr12Mov, LD, H13; Common materials used in the wood industry are: 5WSiCr, 6CrW2Si, SKH, SKD-11, D2;

Hot Searches