- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

laser

-

Place of Origin:

-

China

-

Brand Name:

-

Questt

-

Dimension(L*W*H):

-

98x45x98cm

-

Weight (KG):

-

90 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Product name:

-

Laser Rust Cleaning Machine for Glue Painting coating Derusting

-

Certificate:

-

CE

-

Application:

-

glue removing

-

Laser Power:

-

200Watts

-

Laser source:

-

Fiber laser

-

Speed:

-

0-7000mm/s

-

Laser wavelength:

-

1064nm

-

Service:

-

online and overseas service

-

Certification:

-

ce

-

After Warranty Service:

-

Online support

Quick Details

-

Power:

-

20-1000W

-

Laser Type:

-

Fiber Laser

-

Laser Source Brand:

-

Orion

-

Core Components:

-

laser

-

Place of Origin:

-

China

-

Brand Name:

-

Questt

-

Dimension(L*W*H):

-

98x45x98cm

-

Weight (KG):

-

90 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Product name:

-

Laser Rust Cleaning Machine for Glue Painting coating Derusting

-

Certificate:

-

CE

-

Application:

-

glue removing

-

Laser Power:

-

200Watts

-

Laser source:

-

Fiber laser

-

Speed:

-

0-7000mm/s

-

Laser wavelength:

-

1064nm

-

Service:

-

online and overseas service

-

Certification:

-

ce

-

After Warranty Service:

-

Online support

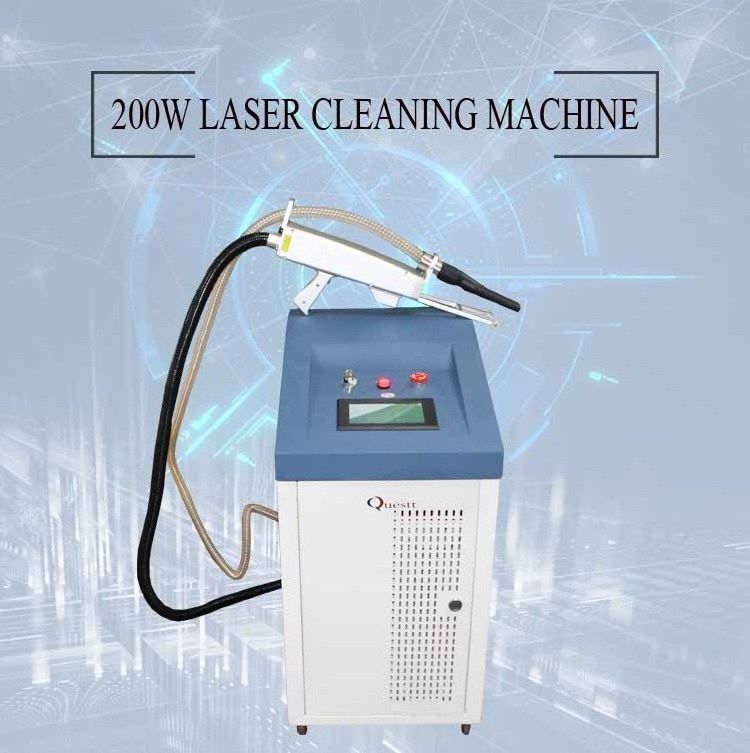

Speedy 200W Fiber Laser Rust Cleaning Machine for Oxide Painting coating Derusting Removal

♥

What is the Specifications and Fetures?

♥

Machine introduction

QA-LC200C is a 200W high power fiber laser clean machine for removing rust on metal surface of big roller, mold and engine etc.

Laser derusting using laser high energy, high frequency, high power characteristics, the high energy instantly deposited in a small area, the use of high-temperature oxidation of the oxide layer.

Specifications:

| Model | QA-LC60 | QA-LC100 | QA-LC200 | QA-LC500 |

| Laser source | Fiber | Fiber | Fiber | Fiber |

| Laser Power | 60W | 100W | 200W | 500W |

| Fiber cable L | 3 M | 3 M | 5 M | 10M |

| Pulse Energy | 1.5 mJ | 1.5 mJ | 2 mJ | 50 mJ |

| Wavelength | 1060nm | 1060nm | 1060nm | 1060nm |

| Frequency | 50-500KHz | 50-200KHz | 20-50KHz | 10-50KHz |

| Clean speed | ≤5 M²/Hour | ≤10 M²/Hour | ≤15 M²/Hour | ≤50 M²/Hour |

| Scann speed | 0-7000mm/s | 0-7000mm/s | 0-7000mm/s | 0-7000mm/s |

| Cooling | Air cooling | Air cooling | Air cooling | Water cooling |

| Dimension | 450*350*500 | 650*350*560 | 900*600*1100 | 1600*1100*1800 |

| Weight | 30Kg | 40Kg | 120Kg | 300Kg |

| Beam width | 10-100mm | 10-100mm | 10-100mm | 10-100mm |

| Optional | Manual | Manual | Manual | Manual |

| Temperature | 5-40 ℃ | 5-40 ℃ | 5-40 ℃ | 5-40 ℃ |

| Voltage | Single Phase 220V, 50HZ | Single Phase 220V, 50HZ | Single Phase 220V, 50HZ | Single Phase 220V, 50HZ |

Comparison with Traditional Clean Methods:

| Comparison | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry ice cleaning |

| Washing Method | non-contact cleaning | contact cleaning | Abrasive contact cleaning | non-contact cleaning |

| Harm to base material | None | Yes | Yes | None |

| Washing Efficiency | High | Low | Low | Mid. |

| Consumable | Power | Chemical Detergent | Abrasive paper, grinder, abrasive stone | Dry Ice |

| Washing result | Very good, very clear | Medium, uneven | Medium, uneven | Good, uneven |

| Precision Washing | Accuracy controllable. High precision | Uncontrollable, low precision. | Uncontrollable, medium precision. | Uncontrollable, poor precision. |

| Safety/Environment | No pollution | Chemical pollution | Dust pollution | No pollution |

| Operation | Easy to operate, portable or automation optional. | Complicated process, higher technical requirement of the operator. Pollution prevention measures required. | Need more time & manpower. Pollution prevention measures required. | Easy to operate, portable or automatic. |

| Investment | High investment on machine. But no consumable, low maintenance cost | Low investment on machine. But expensive consumables | Medium investment on machine. High man-power cost. | Medium investment on machine. High consumable cost. |

Application

Metal workpiece laser derusting, degreasing, laser paint removal, laser removal of zinc and film, laser coating removal, widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, military etc.

Presumably, as the demands of the market increasing , the applications of laser cleaning technolog will be more widely.

Cleaning Samples

1.Q:What is the warranty of the laser cleaning machine?

A:2 years.

2.Q:Are you a factory or trading company?

A:Quesstt Laser is a factory for 22 years.Got import and export License.

3.Q:How about the quality?

A:Technology is from Germany.High quality best price.

4.Q:What is your after-sale service?

A:If needed,Questt Laser offer door to door service !we can send engineers to your factory for assembling ,adjusting and training!

5.Q:How do i get technical support after purchasing?

A:Questt Laser offer online service in English through Skype,WhatsAPP,Wechat or Email etc .If need remote operation,we can use TeamViewer software.

6.Q:How can i get assurance of my Payment?

A:Alibaba have Trade Assurance,you can pay throught Alibaba first.