- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V

-

Power:

-

2.2-90kw

-

Key Machines:

-

Chain Plate Conveyor

-

Dimension(L*W*H):

-

Size customization

-

Warranty:

-

1 year

-

Type:

-

Mining Material Feeder

-

Material:

-

Carbon Steel

-

Feature:

-

Simple Operation

-

Usage:

-

Conveying Material

-

Capacity(t/h):

-

75-1250t/h

-

Power(kw):

-

2.2-90kw

-

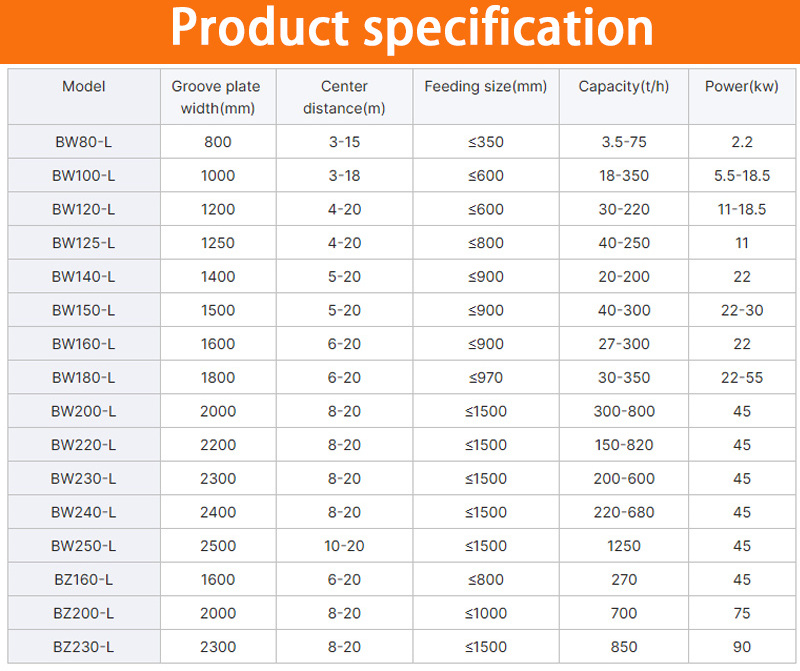

Width of trough plate(mm):

-

800-2500mm

-

Max feeding size(mm):

-

350-1500mm

Quick Details

-

Machinery Capacity:

-

75-1250t/h

-

Brand Name:

-

RD

-

Weight:

-

5800 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V

-

Power:

-

2.2-90kw

-

Key Machines:

-

Chain Plate Conveyor

-

Dimension(L*W*H):

-

Size customization

-

Warranty:

-

1 year

-

Type:

-

Mining Material Feeder

-

Material:

-

Carbon Steel

-

Feature:

-

Simple Operation

-

Usage:

-

Conveying Material

-

Capacity(t/h):

-

75-1250t/h

-

Power(kw):

-

2.2-90kw

-

Width of trough plate(mm):

-

800-2500mm

-

Max feeding size(mm):

-

350-1500mm

High Pressure Heavy Stone Chain Plate Type Feeder Sand Stone Material Conveying Equipment Mining Chain Plate Feeder Conveyor

Chain plate feeder is divided to heavy type, medium type and light type, it's suitable for different size and packing density; according the drive type, it's divided to right drive and left drive, it's the common equipment for crusher feeding in mineral dressing plants and cement plants.Long distance chain apron iron ore plate feeder ?is auxiliary equipment for crushingprocess used to feed materials continuously and uniformly to primary crusher through feed bin. It also used for short distance transport material, particularly useful for conveyance of materials of large specific gravity, larger particles and strong abrasive.

Working Principle:

The devices are installed on the bottom of the ore bin outlet, the ore fall onto the leakage board at the chute bottom, the bottom of the leakage board is fixed on the idler, and through the eccentric institutions to connect the leakage board and the reducer together, and then through the coupling lined the motor. During the operation the motor drive the reducer through the coupling, and through the eccentric dish and the leaking plate, which is at the bottom of the frame also between the idlers, to move in reciprocating linear way, and achieve the feed uniformly.

Features:

1.Smoothly running and long service life

3.Super-large capacity with combination of crusher equipment

4.Impact resistance and long time

5.Supporting high impact loads came from strength of body

6.Good performance-conditioning, no flushing phenomenon of materials

1. 24 hours all day service.

2. Can be customized according to customer needs.

3. Check again before we send the goods.

4. Send the goods on time.