- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Deyi

-

Voltage:

-

380V 50HZ

-

Name:

-

Extrusion Machine

-

Raw material:

-

PLA

-

Processing Type:

-

Exturding Machine

-

Final product:

-

PLA ABS PA NYLON

-

Capacity:

-

250KG/H

-

Keywords:

-

Sheet Line

-

Application Field:

-

Thermoset Plastics

-

Finished Products:

-

Foam Thermocol Plate

-

Plastic Machine:

-

Mashines Extrusion

-

Temperature control:

-

Omron Brand

-

Marketing Type:

-

New product 2021

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

55:1

-

Screw Speed (rpm):

-

500 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Deyi

-

Voltage:

-

380V 50HZ

-

Name:

-

Extrusion Machine

-

Raw material:

-

PLA

-

Processing Type:

-

Exturding Machine

-

Final product:

-

PLA ABS PA NYLON

-

Capacity:

-

250KG/H

-

Keywords:

-

Sheet Line

-

Application Field:

-

Thermoset Plastics

-

Finished Products:

-

Foam Thermocol Plate

-

Plastic Machine:

-

Mashines Extrusion

-

Temperature control:

-

Omron Brand

-

Marketing Type:

-

New product 2021

Product Overview

PLA PBAT degradable lunch box making machine

This machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes,supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

PRODUCT DESCRIPTION

SALES AND SERVICE NETWORK

Products Show

PRODUCT SPECIFICATIONS

|

One-step automatic extrusion blister forming machine

|

|

|

|

|

||||

|

Voltage

|

380V50HZ

|

Labor required for each shift of production line

|

2 people

|

|

||||

|

Materials used |

Calcium carbonate, polypropylene, talc, polylactic acid, PBAT, starch, straw, bamboo powder and other plant fibers

|

|

|

|

||||

|

Product type |

Bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc.

|

|

|

|

||||

|

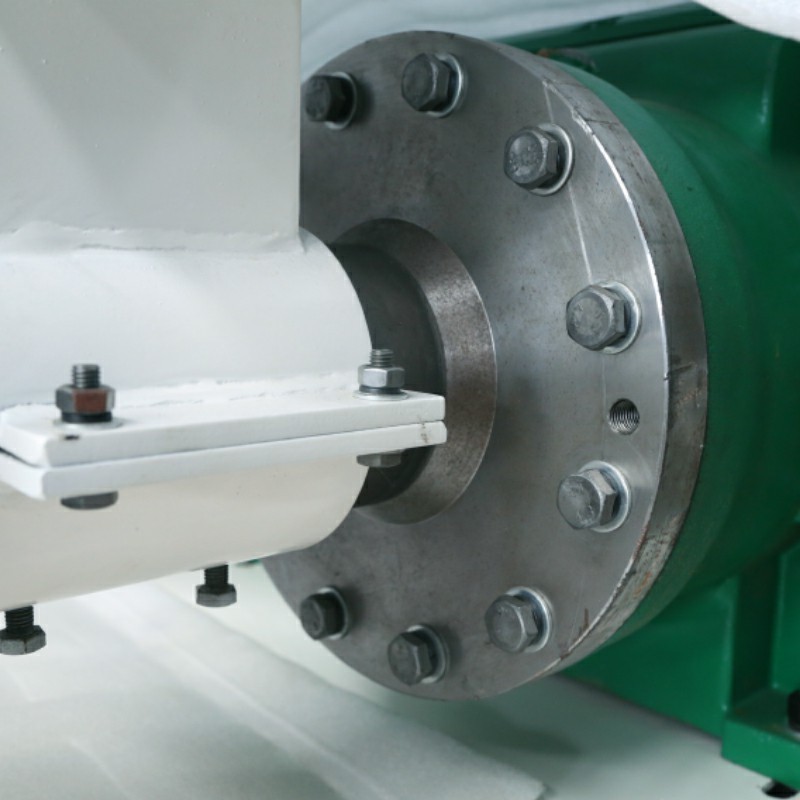

Extruder

|

|

|

|

|

||||

|

Screw material

|

38CrMoAIA

|

Nitriding depth of screw (mm)

|

0.6-0.7

|

|

||||

|

Screw hardness

|

>HV840

|

Screw barrel hardness

|

>HV940

|

|

||||

|

Screw speed (r/min)

|

10~80

|

Blister limit (Pa)

|

2×102

|

|

||||

|

Heating system

|

Cast aluminum ring

|

Cooling system

|

Air-cooled

|

|

||||

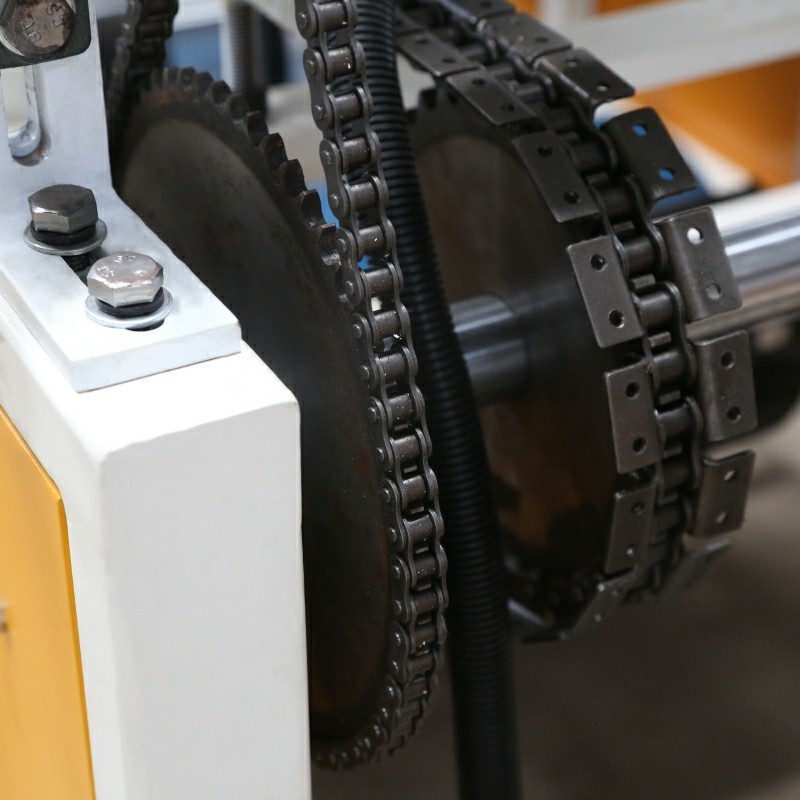

|

Gear box

|

Helical gear

|

Screw heat treatment

|

Carburizing and grinding teeth

|

|

||||

|

Die heating system

|

Stainless steel heating rod

|

Die structure

|

Straight cone hanger T-shaped head

|

|

||||

|

Drive

|

Hydraulic transmission

|

Die design

|

Six-sided hard chrome plating and polishing

|

|

||||

|

Forming machine

|

|

|

|

|

||||

|

Motor (kw)

|

1.5

|

Forming depth (mm)

|

80

|

|

||||

|

Vacuum pump speed (m3/h)

|

80

|

Sheet thickness (mm) |

0.2-2.5

|

|

||||

|

Blister limit (Pa) |

2×102

|

Air compressor (L)

|

100

|

|

||||

|

Air pressure (mpa) |

0.5~0.7

|

Blister method

|

Double suction or four suction |

|

||||

FAQ

Q:Why I choose your company?

A:a) We are the Leading PLA and foam lunch box machine Manufacturer in China.

b) We have made PLA and foam lunch box machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

A:a) We are the Leading PLA and foam lunch box machine Manufacturer in China.

b) We have made PLA and foam lunch box machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

Hot Searches