- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fenqiang

-

Model Number:

-

FQ-QP-039

-

Product Name:

-

Quartz Glass Plate

-

Material:

-

99.99% Pure Quartz

-

Color:

-

Transparent

-

Key word:

-

Quartz Glass Piece

-

Package:

-

Carton

-

Work Temperature:

-

1100 Degrees Celsius

-

Size:

-

Customer's Requirement

-

Density:

-

2.2g/cm3

-

MOQ:

-

1 Piece

Quick Details

-

Type:

-

Clear Quartz Plate

-

Application:

-

Optical

-

Thickness:

-

0.5-100mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fenqiang

-

Model Number:

-

FQ-QP-039

-

Product Name:

-

Quartz Glass Plate

-

Material:

-

99.99% Pure Quartz

-

Color:

-

Transparent

-

Key word:

-

Quartz Glass Piece

-

Package:

-

Carton

-

Work Temperature:

-

1100 Degrees Celsius

-

Size:

-

Customer's Requirement

-

Density:

-

2.2g/cm3

-

MOQ:

-

1 Piece

Product Description

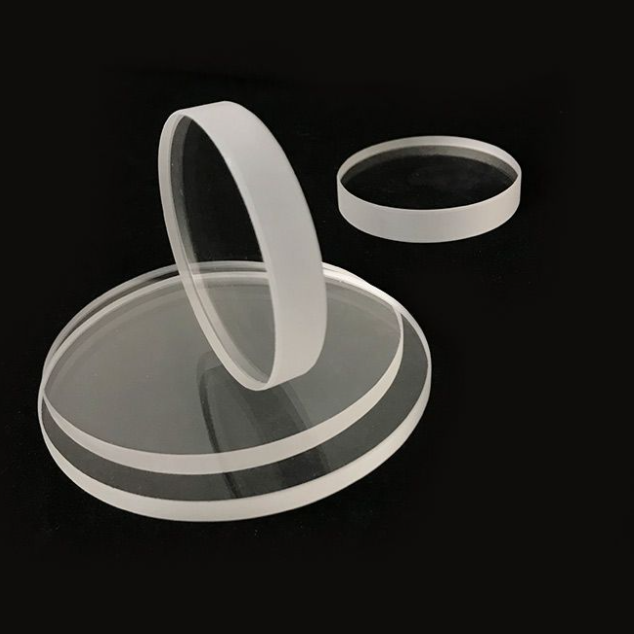

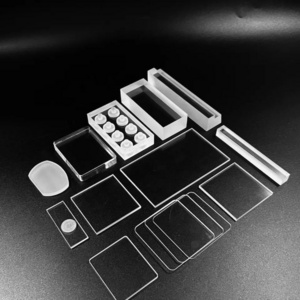

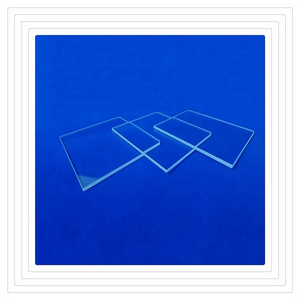

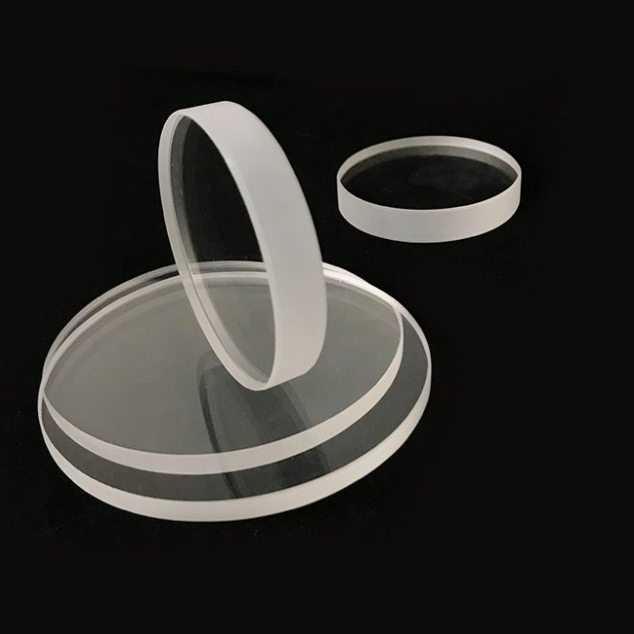

Quartz Glass Plates

The quartz plate or disc we produced is a high-quality product used in various applications including semiconductor, optics,

electronics, medical treatment, bio-engineering and laser industries.

Characteristic:

Our quartz plate achieves very low coefficient of thermal expansion.

It performs strong resistance to high temperature.

The high chemical purity promises the excellent performances.

High corrosion resistance keeps it stable in almost every application.

Extensive optical transmission from ultra-violet to infra-red increases its applications in many areas.

Excellent electrical insulation qualities enable it with excellent performance in electronic industries.

electronics, medical treatment, bio-engineering and laser industries.

Characteristic:

Our quartz plate achieves very low coefficient of thermal expansion.

It performs strong resistance to high temperature.

The high chemical purity promises the excellent performances.

High corrosion resistance keeps it stable in almost every application.

Extensive optical transmission from ultra-violet to infra-red increases its applications in many areas.

Excellent electrical insulation qualities enable it with excellent performance in electronic industries.

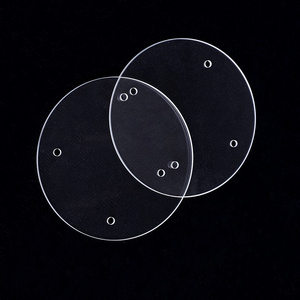

Specification

|

item

|

value

|

|

Type

|

Clear Quartz Plate

|

|

Application

|

Optical

|

|

Thickness

|

0.5-100mm

|

|

Shape

|

Circular Shape

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

Fenqiang

|

|

Model Number

|

FQ-QP-039

|

|

Processing Service

|

Bending, Welding, Punching, Decoiling, Cutting, Moulding

|

|

Product Name

|

Quartz Glass Plate

|

|

Material

|

99.99% Pure Quartz

|

|

Color

|

Transparent

|

|

Key word

|

Quartz Glass Piece

|

|

Package

|

Carton

|

|

Work Temperature

|

1100 Degrees Celsius

|

|

Size

|

Customer's Requirement

|

|

Density

|

2.2g/cm3

|

|

MOQ

|

1 Piece

|

Specification

|

item

|

value

|

|

Type

|

Clear Quartz Plate

|

|

Application

|

Optical/Semi/Industry

|

|

Thickness

|

0.5-100mm

|

|

Shape

|

Circular Shape

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

Fenqiang

|

|

Model Number

|

FQ-QP-037

|

|

Processing Service

|

Bending, Welding, Punching, Decoiling, Cutting, Moulding

|

|

Product Name

|

Quartz Glass Plate

|

|

Material

|

99.99% Pure Quartz

|

|

Color

|

Transparent

|

|

Key word

|

Quartz Glass Piece

|

|

Size

|

Customer's Requirement

|

|

Package

|

Carton

|

|

Work Temperature

|

1100 Degrees Celsius

|

|

Density

|

2.2g/cm3

|

|

MOQ

|

1 Piece

|

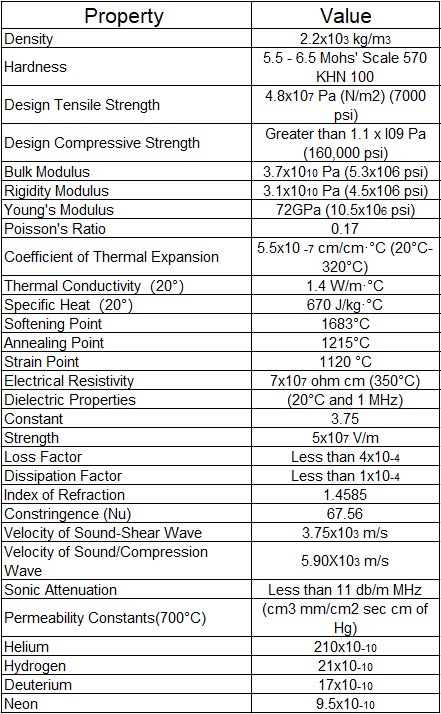

Technical Data

Products Description

Our Workshop

Product Processing

1. Mulititool Machining.

The quartz material will be stuck on the board and be absorbed by electromagnet on the workbench. In order to cut the material,

the workbench rises slowly by electromotor and the blade revolves high-speed and repeated. According to the requirement of the

customer, the machine can cut the whole material into 1-1000mm wafer. The advantage of this step is stable size and low defective

percentage.2. Milling.

The surface of the material can be processed into plane, vertical plane, inclined plane and different kinds of groove or formed

surface by the rotary milling cutter of the machine. It also can be made into spiral groove, cam and the complex thread and spline

shaft.

3. Cylindrical Cutting.

The parallel misalignment of the product can reach 0.01millimeters after cutting. The main reason to get accurate product is that

the computer can control this machine.

4. Chamfering of edge

The quartz product's edge or shape will be changed smooth and rounded. Because of this, it is not easy to broke and damage with

eternal force for the quartz piece or other quartz product.

5. Grinding.

different kinds of lapping machines is chosen by producing different sizes, shapes, and accuracies products. In fact, it is not

worry about the resistance of the grinding to damage the product. The reason is that the resistance is too small and it grides two

sides evenly. The benefit of this step is high production efficiency.

6. Manual grinding.

The traditional manual grinding is took by the high accuracy quartz component from the customer. The technician of our factory own

excellent workmanship and skillful technique. They can control the accuracy deviation under 0.07mm.

7. Polishing.

Workers is polishing the quartz material with polishing wheels. Polishing wheels are composed of canvases, felts and leather. The

quartz piece is clamped by metal disks with polishing agent. The quartz piece become dazzling light after the speed of 20m/s..

8. Quality inspection

The high quality is reputation guaranteed of our factory. There is a set of scientific and rigorous quality control system in our

factory no matter the raw material, semi-finish product and finished product. The final purpose is to satisfy the requirement of

the customer.

The quartz material will be stuck on the board and be absorbed by electromagnet on the workbench. In order to cut the material,

the workbench rises slowly by electromotor and the blade revolves high-speed and repeated. According to the requirement of the

customer, the machine can cut the whole material into 1-1000mm wafer. The advantage of this step is stable size and low defective

percentage.2. Milling.

The surface of the material can be processed into plane, vertical plane, inclined plane and different kinds of groove or formed

surface by the rotary milling cutter of the machine. It also can be made into spiral groove, cam and the complex thread and spline

shaft.

3. Cylindrical Cutting.

The parallel misalignment of the product can reach 0.01millimeters after cutting. The main reason to get accurate product is that

the computer can control this machine.

4. Chamfering of edge

The quartz product's edge or shape will be changed smooth and rounded. Because of this, it is not easy to broke and damage with

eternal force for the quartz piece or other quartz product.

5. Grinding.

different kinds of lapping machines is chosen by producing different sizes, shapes, and accuracies products. In fact, it is not

worry about the resistance of the grinding to damage the product. The reason is that the resistance is too small and it grides two

sides evenly. The benefit of this step is high production efficiency.

6. Manual grinding.

The traditional manual grinding is took by the high accuracy quartz component from the customer. The technician of our factory own

excellent workmanship and skillful technique. They can control the accuracy deviation under 0.07mm.

7. Polishing.

Workers is polishing the quartz material with polishing wheels. Polishing wheels are composed of canvases, felts and leather. The

quartz piece is clamped by metal disks with polishing agent. The quartz piece become dazzling light after the speed of 20m/s..

8. Quality inspection

The high quality is reputation guaranteed of our factory. There is a set of scientific and rigorous quality control system in our

factory no matter the raw material, semi-finish product and finished product. The final purpose is to satisfy the requirement of

the customer.

Application

Widely

used in electric light source, electrical appliances (electric), semiconductor, optical communications, military

industry, metallurgy, building materials, chemical, machinery, electricity, environmental protection and other fields

industry, metallurgy, building materials, chemical, machinery, electricity, environmental protection and other fields

Hot Searches