Greenhouse sink, greenhouse sink production and processing manufacturer

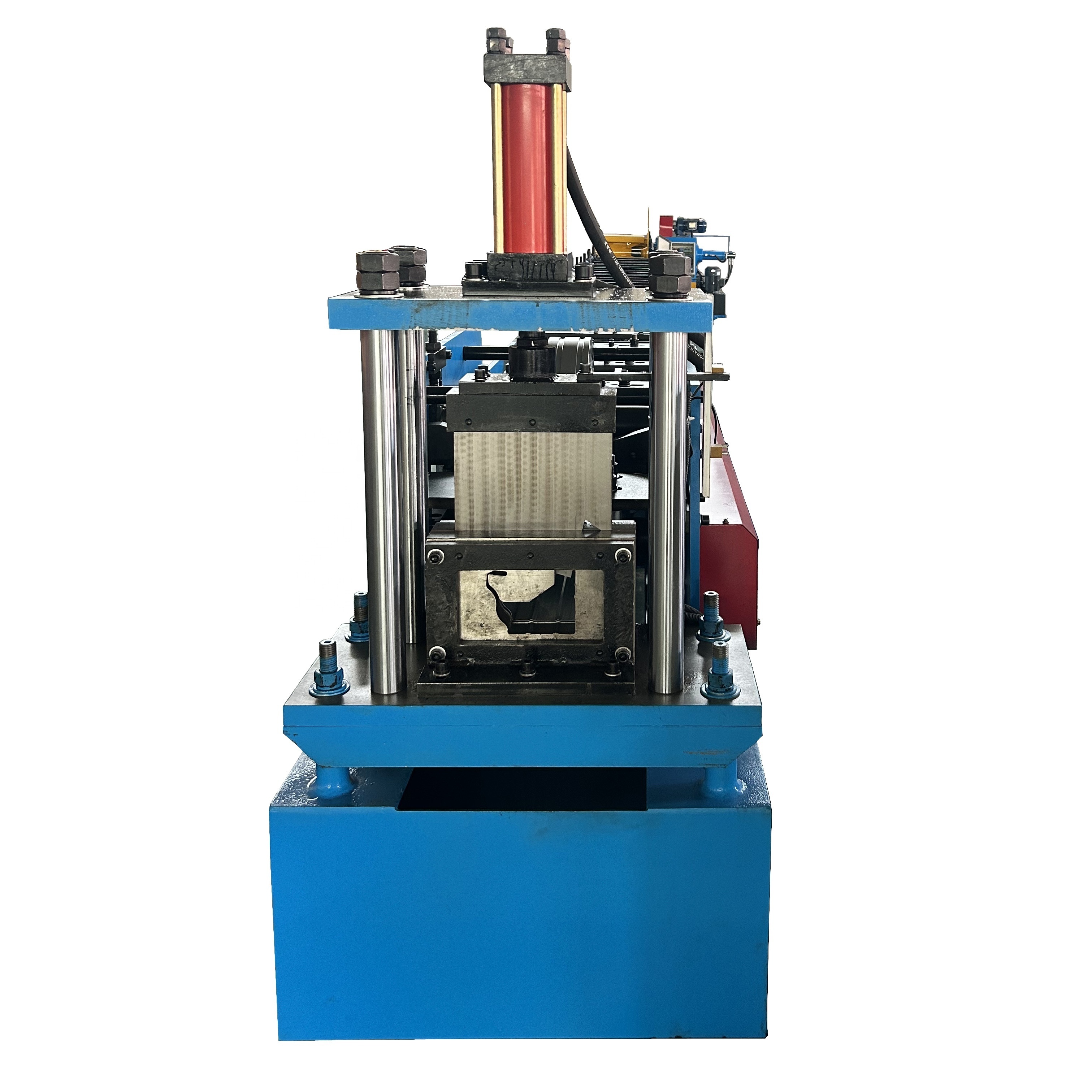

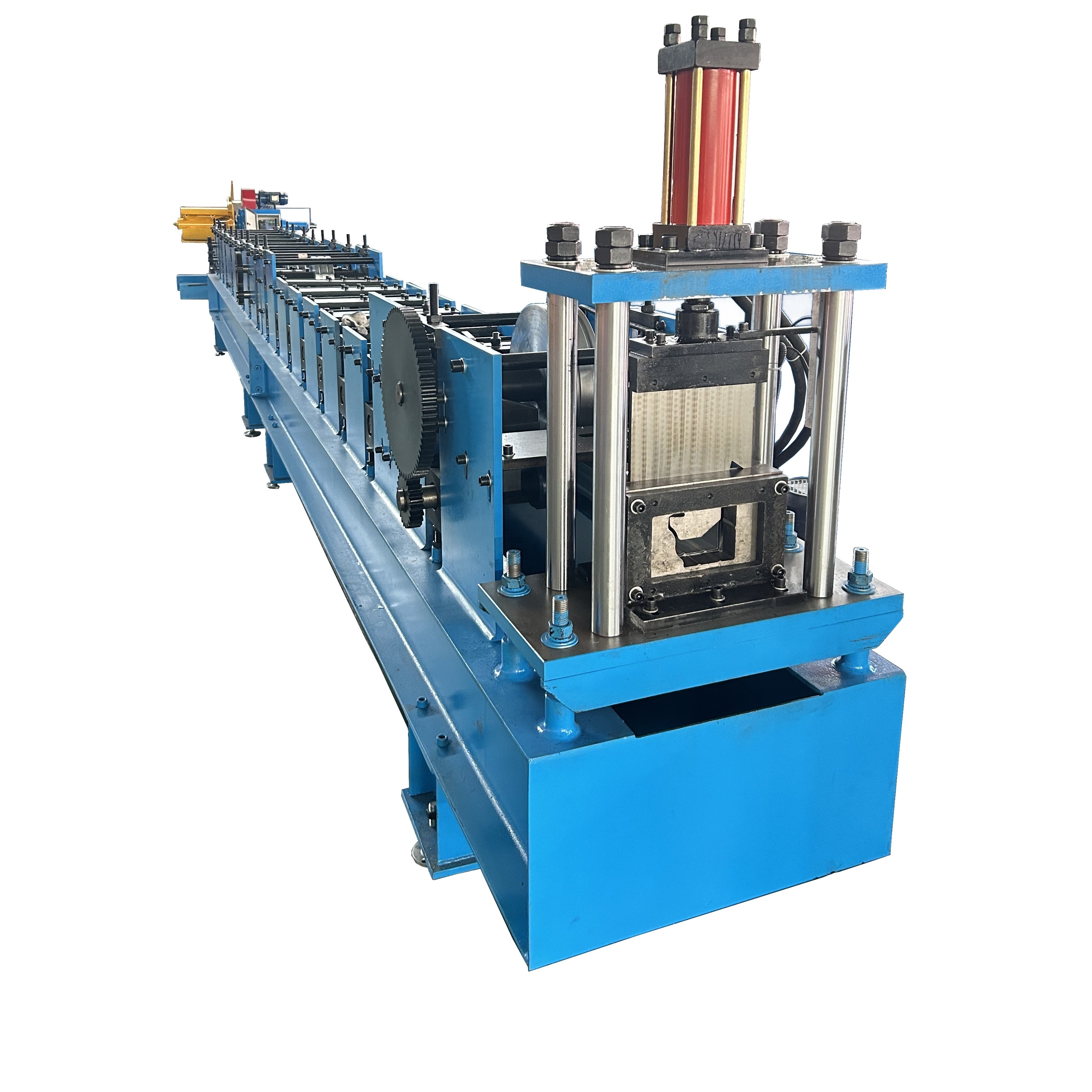

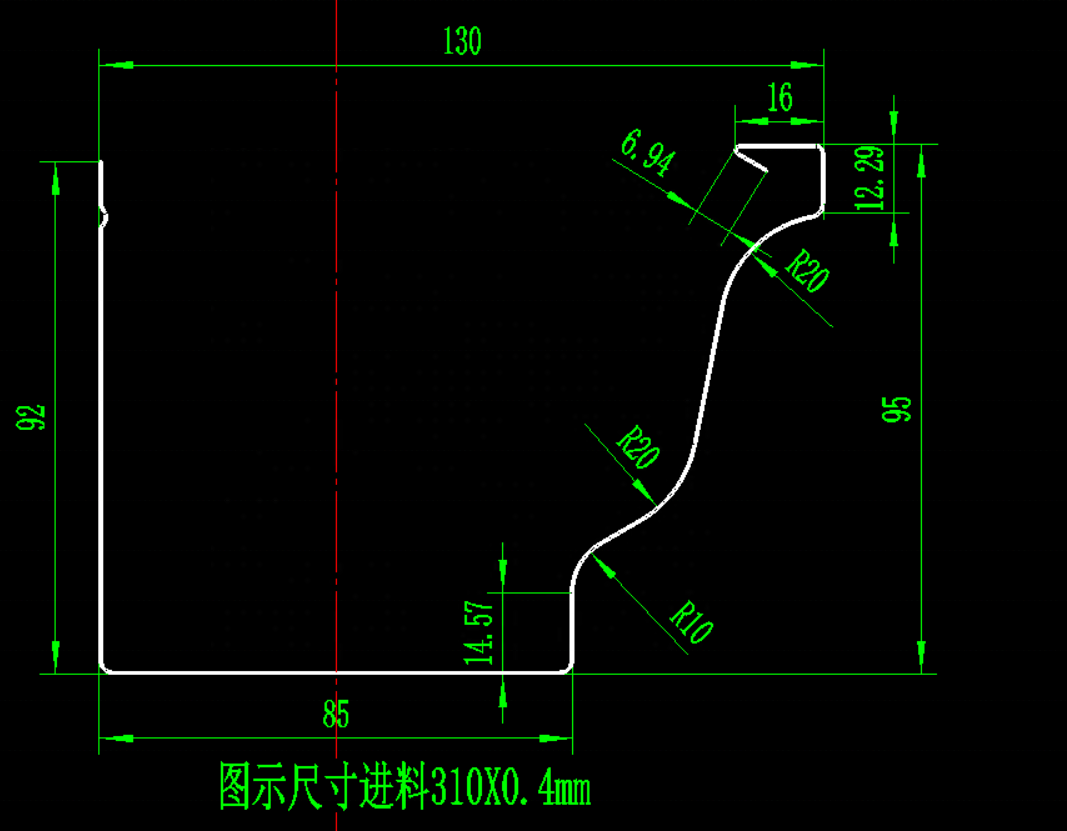

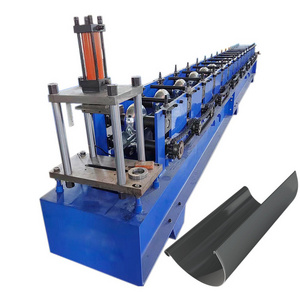

The main function of the gutter plate sink is to collect dew and drain water. Generally, galvanized sheets with high zinc layer are used, which require high anti-corrosion resistance. They are widely used in multi-span greenhouses and smart greenhouses. Multi-span greenhouse gutter board equipment, glass greenhouse gutter board equipment, film gutter board equipment manufacturers, specializing in the production of various gutter board equipment, gutter forming machines, processing gutter boards, production of drainage channels, and rain gutters.

Supporting professional gutter sink production line, production and processing of different thicknesses, zinc layer galvanized plate sinks, drainage gutters, middle gutters, side gutters, punching, forming, ready-made finished products, gutter drainage funnels, pressure plate seats, brackets , all accessories are available

The roofs of multi-span greenhouses are divided into round arch type and pointed roof type. The water on the roof will flow down to the sink (gutter), so we only need to make a slope in the direction of the gutter. The slope in the direction of the water tank is generally about 2.5 thousandths, and the slope in the direction of a 4-meter bay is about 1 cm. The slope of the greenhouse is divided into two types: one-way slope and two-way slope. If the distance between the greenhouses is more than 40 meters, a two-way slope is generally used. The water tank is high in the middle and low on both sides, and the water flows to both sides. If the distance between the greenhouses is less than 40 meters, you can use unilateral drainage, that is, block one side of the sink and drain water only to the other side.

Another situation is that the distance in the direction of the gutter is too long, and the drainage on both sides cannot meet the drainage indicators in heavy rain conditions, so it is necessary to add an internal drainage outlet in the middle of the gutter. That is, choose the middle position and open an opening at the bottom of the sink so that rainwater in the middle can flow into the greenhouse.

Due to the needs of the greenhouse market, the demand for various types of gutter panels is increasing day by day, but there are many types on the market, including center gutter and side gutter. The gutter regulations used in different greenhouses are different, including inside-out and outside-out. Turning and punching are different from the north to the south. Customized gutter board equipment is supplied directly from the manufacturer and the quality is consistent.