- Product Details

- {{item.text}}

Quick Details

-

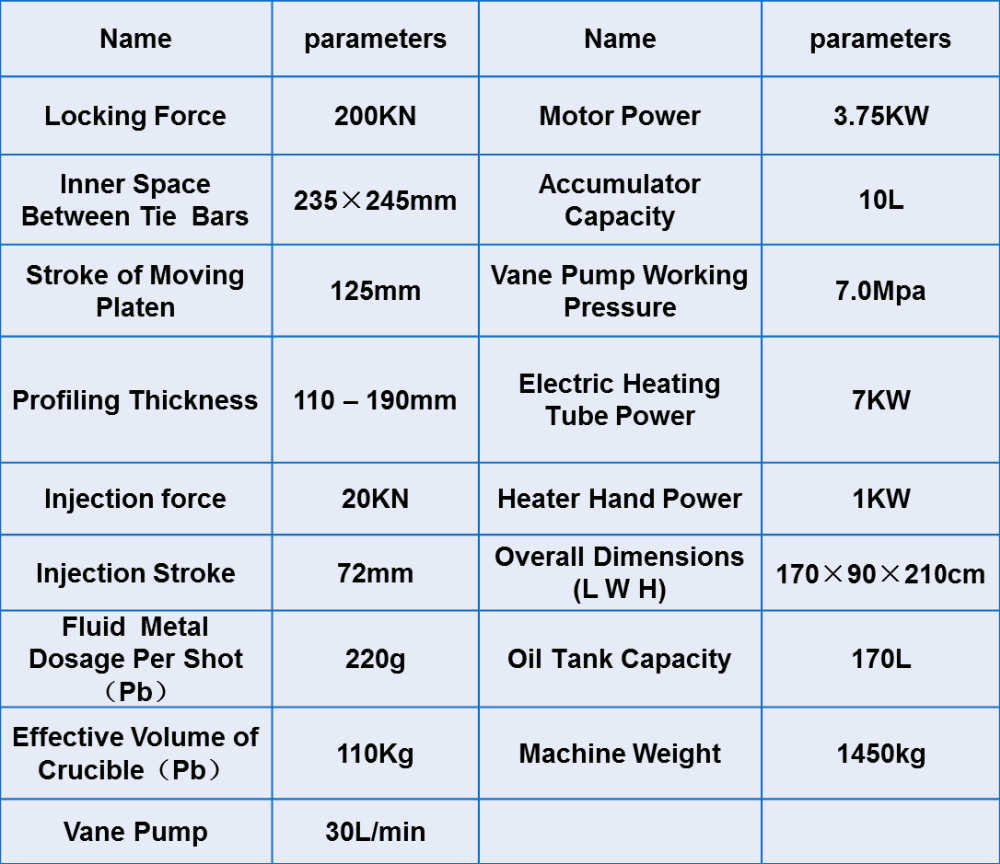

Max.Thickness of Die Block (mm):

-

190 mm

-

Min.Thickness of Die Block (mm):

-

110 mm

-

Injection Force(kN):

-

20kN

-

Injection Stroke(mm):

-

125mm

-

Ejection Force(kN):

-

20 kN

-

Ejection Stroke(mm):

-

72 mm

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

as customer required

-

Dimension(L*W*H):

-

1700*900*2100mm

-

Weight (KG):

-

1400

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage 1:

-

Lead sinker

-

Cleaning Type:

-

Die Casting

-

Melting Types:

-

Hot Chamber

-

Machine Types:

-

vertical

-

usage 2:

-

fishing Lead sinker

-

melting method:

-

electric heating

-

power supply:

-

50/60 Hz, 3phases

-

Weight:

-

1450KG

Quick Details

-

Inner Space Between the Bars (Vertical)(mm):

-

235mm

-

Die-locking Force (kN):

-

200kN

-

Inner Space Between the Bars (Horizontal)(mm):

-

245mm

-

Max.Thickness of Die Block (mm):

-

190 mm

-

Min.Thickness of Die Block (mm):

-

110 mm

-

Injection Force(kN):

-

20kN

-

Injection Stroke(mm):

-

125mm

-

Ejection Force(kN):

-

20 kN

-

Ejection Stroke(mm):

-

72 mm

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

as customer required

-

Dimension(L*W*H):

-

1700*900*2100mm

-

Weight (KG):

-

1400

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage 1:

-

Lead sinker

-

Cleaning Type:

-

Die Casting

-

Melting Types:

-

Hot Chamber

-

Machine Types:

-

vertical

-

usage 2:

-

fishing Lead sinker

-

melting method:

-

electric heating

-

power supply:

-

50/60 Hz, 3phases

-

Weight:

-

1450KG

fishing Lead sinker making machine

This vertical die casting machine is initiated by our won factory independently, specially design for die casting lead or zinc alloy embedded mold such as lead fishing sinker etc.

Special automation control systems, security monitoring systems, energy-saving design which makes this die casting machine has high reliability, efficiency and automation. Its production of zinc alloy, lead alloy, tin alloy products, with the best surface quality, polishing, plating, painting, it has been widely used in manufacturing gear, electrical and electronic castings, auto parts and other fields.

Features:

—Auto-mould height adjustment: ensure fast adjusting, stable clamping and high durability;

—Automatic rising-lowering: ensure fast adjusting, stable sticking, durability and convenience;

—Adopt integrated injection cylinder, which has high efficiency, stability and safety;

—mold closing protective system can protect operator’s security, and reduce mode damage probability.

— Pneumatic safety door: run automatically after device starting, protect staff’s personal safety, and avoid industrial injury.

—Control panel with easy operation and safe locking protection design.

—The improved furnace adopts advanced design and material, more energy saving and durable;

—Smart energy saving system reduces energy consumption of non-work state efficiently;

— Local temperature control system provides more comfortable and safer work environment;

— Mold closing/opening adopts electronic fix detecting system, and its precision is high;

— The alarm information can be found conveniently and timely;

—Injection operation, opening and locking mold. can be set on the screen rapidly and accurately;

—Delta PLC control system with text interface configuration is convenient and flexible;

—High-strength steel alloy tie bar with chromium plated for high wear resistance and long service life.

—Thickened platen was made of excellent ductile cast iron with high rigidity, even stress and little distortion, which ensures the stability of die casting machine.

—Diagonal five point toggle was made of ductile cast iron with high rigidity, high durability, and more stable mold opening and closing;

—Hot set parts of injection system adopt imported high quality hot set steel;

Technical parameter

what this machine can make.....

lead fishing, lead sinker, car brake cable, motorcycles brake cable,bike brake cable,key, knitting needle,electrical parts and so on...............

1. All the instructions and paper materials in English, to facilitate overseas customers;

1) Provide a full package of English machine operation and maintenance instructions, easy to use.

2) Provided with English remarks Video: include instructions for use and solutions of common problems.

3) Provide English accessories table;

2. Custom services

We provide customized services, if you have special requirements for die-casting equipment, we will provide professional customized services.

3. Timely Reply: Your questions online, we guarantee to reply within 12 hours;

4. After Service: As in the process of using machine ,if u have any problems can contact us by e-mail, we ensure the advisory services reply will be given within 24 hours;

Packaging: iron case or according to customer requirements;

Delivery: 30 days after receipt of deposit;

Our factory Jiaxing Xiuzhou District Wangdian Dajian equipment factory ( the former Jiaxing Wangdian Huada equipment factory) is a professional die-casting machine manufacturing enterprises, engage in die-casting machine’s technology development, production and marketing. We have more than twenty years operating history in die-casting machine manufacturing .

" Intention of manufacturing each product, intentions treat every customer " is factory’s business philosophy, which has been adhering so far. We have established long-term cooperation with more than one hundred companies, customers all over the country and some overseas regions. Our high-quality products and intentions service have won numerous customers’ trust and praise.

Q1: Is your company a trading company or manufacturer?

A: Our company is a manufacturer, we have been focused on the production of die casting machine for more than 20 years.

Q2: where your machine been exported before?

A: Our machine have been exported to customers in Europe, South America, The middle east, India, Asia and so on.

Q3:Does your machine easy to operate? What if I have no operating experience before?

A:Our machine have computer control system with computer screen display, it is very easy to operate.What’s more, we have English instruction and operating video with English annotation. All of these will be send you with the machine.

We have our own after-sale online services, if you have any problem you can contact us by email, we will reply in 24hours and send you instruction with text/picture/video to help you solve the problem.

Q4: How's your after-sale service?

Our machine have one year warranty. For the new machine, we will send some free wearing parts to you.

What’s more, we have online service, if you have any problems you can contact us by mail. We will reply in 24hours to help you solve the problem.

We have engineer overseas service, if you really need you can contact us for details.

Q5: What should I do if I want to order?

You can contact us through Alibaba or by sending mail , please write your detail requirements of machine and your products information to help us to give you useful suggestion.