- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800*1300*2300mm

-

Power (kW):

-

26 kW

-

Weight (KG):

-

10000 KG

-

Total Pressure:

-

11.2MN

-

Heating Platen Size:

-

600*6200*1(mm)

-

Daylight:

-

200mm

-

Piston Stroke:

-

200mm

-

Working Layer.:

-

1

-

Hydraulic Cylinder Diameter(mm):

-

400mm

-

Hydraulic system pressure:

-

16.4

-

Close mould speed(mm/s):

-

.>=12

-

open mould speed(mm/s):

-

>=12

-

Power:

-

26 KW

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2800*1300*2300mm

-

Power (kW):

-

26 kW

-

Weight (KG):

-

10000 KG

-

Total Pressure:

-

11.2MN

-

Heating Platen Size:

-

600*6200*1(mm)

-

Daylight:

-

200mm

-

Piston Stroke:

-

200mm

-

Working Layer.:

-

1

-

Hydraulic Cylinder Diameter(mm):

-

400mm

-

Hydraulic system pressure:

-

16.4

-

Close mould speed(mm/s):

-

.>=12

-

open mould speed(mm/s):

-

>=12

-

Power:

-

26 KW

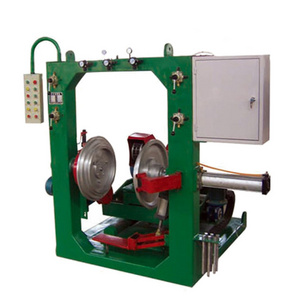

Customized Plate Tyre Tread Vulcanizing Plant/Tyre Retreading Repairing Machine

1. Production Description:

| Model | Total Press(MN) | Heating Plate Size(mm) | Plates Daylight | Working Layer No. | Piston Stroke(mm) | Hydraulic Cylinder Diameter(mm) | Hydraulic Cylinder No.(group) | Open Mould Speed(mm/s) | Close Mould Speed(mm/s) | Hydraulic System Pressure(Mpa) |

| XLB-600*6200*1 | 11.20 | 600*6300*1 | 200 | 1 | 200 | 400 | 6 | >=12 | >=12 | 16.4 |

Rubber vulcanizer is used for vulcanizing all kinds of rubber and plastic mould products, and non-mould products. Being frame type, the machine is different from the column type , it is allowed to install larger diameter hydraulic cylinder, reducing the quantity of cylinders, with simple structure, and little maintaince wok. The frame can bear more stress and it has cheap price, nice surface, easy to operate.

2.Frame vulcanizing pree lightspots display:

- Electrical control system:

Complete the perfect control system (including wire and cable and safety protection devices, etc.) ,Use automatic time relay,can achieve Automatic close mold, exhaust , stuffy , Vulcanization time , supplement pressure ,open mold etc working process, also the automatic control and hand control can be switched easily.

- All angles of frame rubber vulcanizing press pictures:

Frame Plates are constituted with welded Q235 steel plates, 40mm thickness ,through mechanical ball blast rust removal, spraying zinc rich series paint, shake to remove stress, then transferred into mechanical producing

Frame vulcanizing press advantages:

1 Simple and convenient structure ,flexible operation,commodious space.The cylinder and plunger are made up of high –quality materials.

2 Hydraulic station and electric cabinet are Located in both sides of the main engine.

3 Conveniently operated.

4 Without oil spilling or off pressure.

5.Excellent reputation .

6 CE Standards

3.Delivery &payment:

- Delivery lead time: 35-40 days since receiving the deposit

- Packing way:

- 1) wrapped with stretch film, avoid rubbing the paint off thesurface

- 2) wooden packaging can be customized

- 3) key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.

- Term of payment: T/T (30% deposit, 70% balance of B/L) ; L/C

4.Our service:

- Overseas service and technical support can be supplied

- We will get the machines dispatched within the stipulated time

- 24 hours online service, immediate response to your request

- Testing machine is available, make sure customer satisfied with machine's quality

- Help customer to design, make drawing,accept OEM rubber machine

- Arrange shipment and inform customer in advance 7 days before finishing the order

5.Related rubber vulcanizing press display:

Two -way sliding mold curing press: Solid tyre curing frame type vulcanizing press:

6.About us:

- Qingdao shun cheong rubber machinery manufacturing co.,ltd is a chinese manufacturer with establishment in 2007, and have 10 years experience in making various of rubber machines area, also pass the ISO 9001:2008 , SGS, CE certificates too.

- our factory major in rubber kneader/rubber mixing mill ; various of plate vulcanizing press ; 2 roll/3 roll/4 roll rubber calender; rubber batch off cooler; waste tire recycling line;reclaimed rubber production line;conveyor belt production line;rubber seals extruding &vulcanizing line etc...

- Market: our machineries have exported to America, Mexico, ndia, Vietnam, South Africa, Singapore, Malaysia, Indonisia, Australia, Sri Lanka and many other countries and regions

- Professional engineers and teams, then basing on customer requirements, we accept OEM*ODM machines, also oversea engineer service is available

7. Why choose us :

Our Mission. Our Goal. Our Culture.

To provide a More Cost Efficient To get trust from every customers To be professional and progress

Solution for our customers.Suitable is who contacted with us. To show our together. We treat every staffs

the Best Way.Best for customers, for sincerely in communication and our as a family member.Shared and worked

local market and even for our future. professional skills in business, and even together to reach our goals.we'll be

We treat it as our responsibility in every to provide the most suitable machines better and better as long as we all

business. for them to satisfy with their special progress together every minutes.

need. A little change everday makes a

big difference someday