Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

China

-

Brand Name:

-

Hommy

-

Power:

-

1000kw

-

Main power:

-

220V50/60Hz,1 phase or 380V50Hz,3 phase / 220V60Hz,3 phase

-

Eletric current:

-

16A

-

Max production capacity:

-

50L/H

-

hopper capacity:

-

1.7L

-

cylinder capacity:

-

1x1.8L

-

Cooling Type:

-

Air cooled

-

Noise:

-

Ultra quiet 50-55 db

-

After Warranty Service:

-

Online support

Quick Details

-

Type:

-

Vending Machines

-

Dimension:

-

820mmx958mmx1827mm

-

After-sales Service Provided:

-

Video technical support, Online support

-

Warranty:

-

1 Year

-

Place of Origin:

-

China

-

Brand Name:

-

Hommy

-

Power:

-

1000kw

-

Main power:

-

220V50/60Hz,1 phase or 380V50Hz,3 phase / 220V60Hz,3 phase

-

Eletric current:

-

16A

-

Max production capacity:

-

50L/H

-

hopper capacity:

-

1.7L

-

cylinder capacity:

-

1x1.8L

-

Cooling Type:

-

Air cooled

-

Noise:

-

Ultra quiet 50-55 db

-

After Warranty Service:

-

Online support

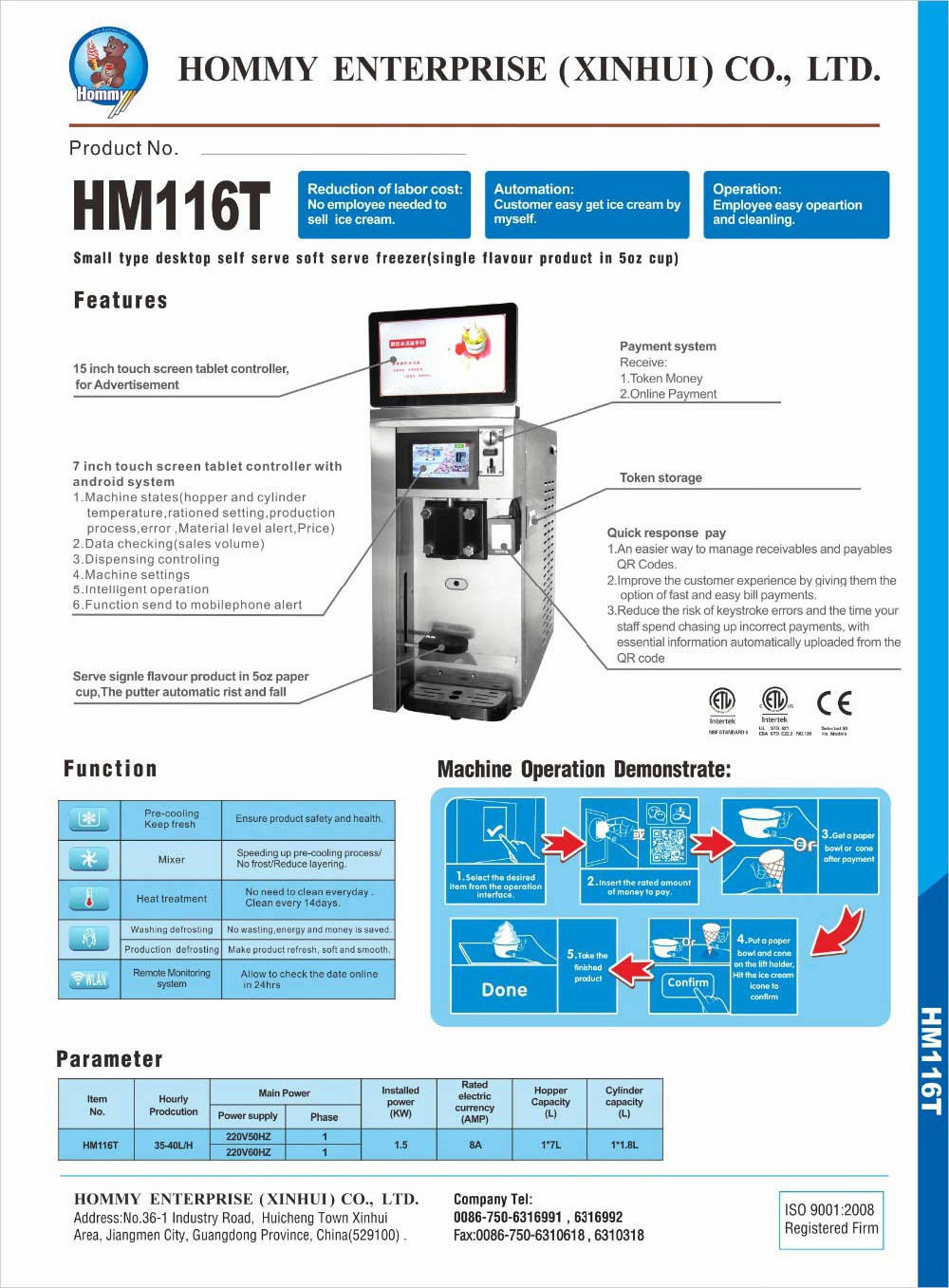

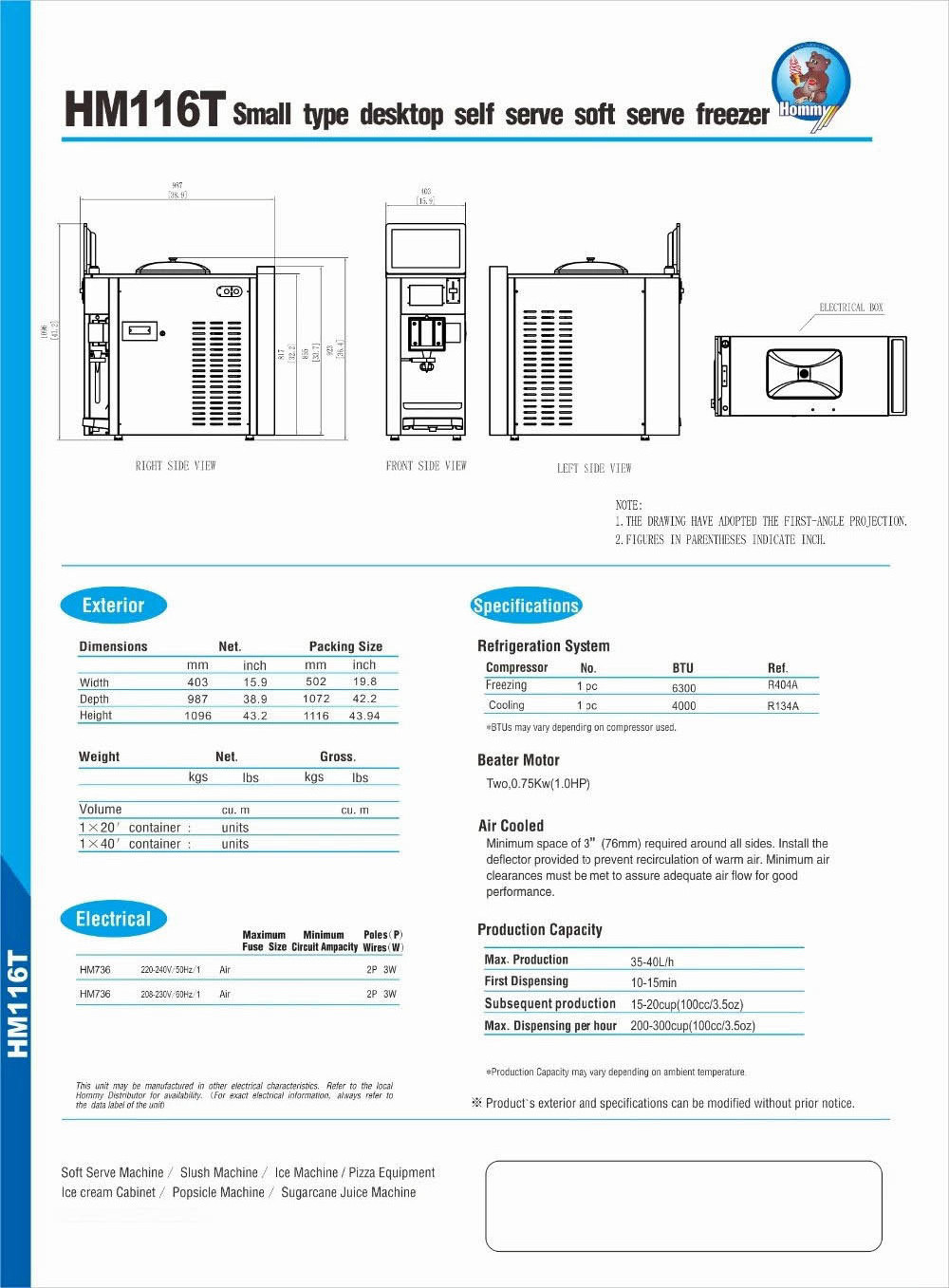

Semi automatic softserve ice cream vending and making machine

| Product Name | Semi automatic softserve ice cream vending and making machine |

| Model ID | HM116T |

| pre-cooling temperature | 2~5 degree |

| Cooling Type | Air cooled |

| Noise | Ultra quiet 50-55 db |

| Voltage | 220V50/60Hz,1phase |

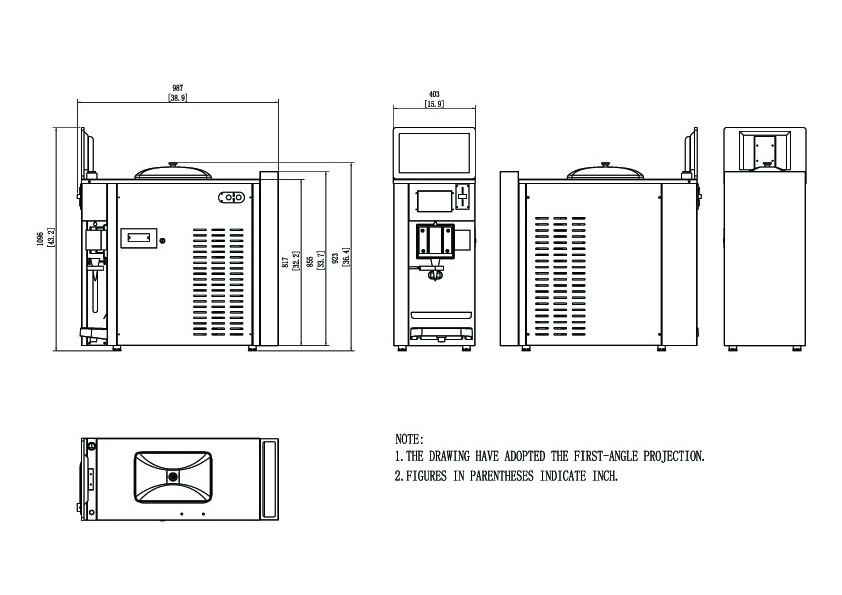

HM116T vending soft ice cream machine size

HM116T Function:Self service soft serve freezer (single flavour,Self Service, pre-cooling , mixer, counter , Heat Treatment, Defrosting, Disinfection, Remoto Control.

* Hardness setting : It is adjustable which is based on the material used.

* Pressure protect sensor.

* Sealed hopper lid ensures mixture sanitation.

* Unique-designed beater in cylinder,Stainless steel one, more durable and contruibutes to a more smooth and creamy product.

* Ultra-quiet design. Noise is reduced to about 55dbs when working.

* Safety productions: High pressure switch prevents comperssor overheat.Themal overload protects from motor overheat.

5oz cup with spoon

P for Pre-cooling: adjustable pre-cooling temperature 2-4ºC.

1. Speed up production process that promotes ideal output.

2. Provide comfortable environment for the mix in the hopper which effectively prevent bacterial from breeding. As a result, material in the hoppers is not spoiling.

3. Keep fresh of the material. The material tank acts as a refrigerator which always maintains in rated temperature. This way, the mix can be stay in the machine over night by stand-by-switch feature in order to keep fresh. By doing so, it reduces labor and daily maintenance costs as the equipment only requires disassembly and cleaning every 7 days.

Gravity feed: expansion tube deliver mix with overrun of about 30%-40% to the freezing cylinder. (programmed control)

M for Mixer:

1. Move the material in the hoppers to keep its fluidity. This way, thermal transmission is optimized, which contributes to speeding up pre-cooling process.

2. No ice block would be delivered to the cylinder during production as there should not be any ice block occuring on the hopper walls.

3. Overrun is increased to obtained smooth texture and attractive color.

4. Reduce layering of raw materials, frozen cylinder phenomenon will not occur, which in return protects the beat and motor. If the material of too high proportion of water goes into the cylinder, it would get frozen. Then, the beater is hard to move. If this trend continues, the motor would get demaged easily due to tense work.

C for Counter:

Allow the operator to view number of servings dispensed.

H for Heat treatment:

suggest to start after business hour. (for soft ice cream only)

The Heat Treatment cycle is to destroy bacteria by raising the temperature of the material in the freezing cylinder and the hopper to a specified temperature for a specified period of time to destroy all pathogenic microbes, and then bringing the temperature back low enough to retard spoilage.

D for defrosting:

1.Washing defrosting: rapidly melt the product in the freezing cylinder into liquid that significantly reduces leftover before washing. Start this funciton and take out all the liquid mix from the machine and then keep into the refrigerator. This way, no wasting is occured. Energy and money is saved.

2. Production defrosting: after long no-dispensing period, you will find the product comes out from the machine with rough texture. Then, start this function to melt the roduct in the freezing cylinder. Next, turn on the production mode to reproduce in order to make the product soft and smooth.

D for disinfection:

Shortern the time spending on cleaning. As a result, business hours is prolonged. There is no need to take off the throat block unit and beater when cleaning. Take out all the liquid and pour water into the hopper. Next start this function to achieve the purpose of machine disinfection.

R for remote monitoring system:

1. Connect with wifi, which allows you to check the date online.

2. To timely discover the machine failure and directly send working diagnosis message to the facotry mnitoring center in order to solve the problem more quickly.

3. To monitor the real-time sales volume as well as liquid level in the hoppers, which alerts to add material.

4. Easlily upgrade of advertising content, background and operation interface of the screen.

Pre-sales professional guidance

Providing production information during the medium-sales in time to ensure the customers to follow up the production schedule.

Shipping Departmnet

Hommy have export licence.We cooperate familiar local shipping fowarder ship out cargo to your destination or door to door service, which is very professional.

After-sales team offer technology support

Specially-assigned persons to manage the hot-lines and emails. Office hours in China: 8:00 AM to 5:15 PM Monday to Saturday, to resolve the problems for customers from different time zones in time.

Provide the solution within 24 hours, no matter terminal clients or agencies, till the problems are solved.

Inner: PE Packing+ Corner Protection

Outer: Fiberboard case

All the machine will be installed and tested before shipping,Meanwhile, the necessary parts and spared parts are offered together free of charge.

Delivery way:

By Sea

By Air

By Express

By Truck

If cooling equipment are shipped by express or by air , there is no refrigerant in the compressor,Because it is inflammable goods

prohibit on plane. Customers must find local professional inject refrigerant into machine can be work.