- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Remax

-

Voltage:

-

AC220V/50Hz

-

Weight (KG):

-

800

-

Warranty of core components:

-

2 Year

-

Control system:

-

Mach 3

-

Application:

-

Metal milling work

-

Spindle:

-

3.2KW Water Cooling Spindle

-

Working area:

-

600X600X200mm

-

Transmission:

-

TBI Ball Screw

-

limt switch:

-

OMRON

-

inverter:

-

Fuling

-

Table:

-

Iron T-slot and table moving

-

Driving system:

-

Leadshine hybrid servo motor and driver

-

Frame:

-

Cast-iron

Quick Details

-

Working Table Size(mm):

-

600x600x200

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Remax

-

Voltage:

-

AC220V/50Hz

-

Weight (KG):

-

800

-

Warranty of core components:

-

2 Year

-

Control system:

-

Mach 3

-

Application:

-

Metal milling work

-

Spindle:

-

3.2KW Water Cooling Spindle

-

Working area:

-

600X600X200mm

-

Transmission:

-

TBI Ball Screw

-

limt switch:

-

OMRON

-

inverter:

-

Fuling

-

Table:

-

Iron T-slot and table moving

-

Driving system:

-

Leadshine hybrid servo motor and driver

-

Frame:

-

Cast-iron

Product Information

Application scene

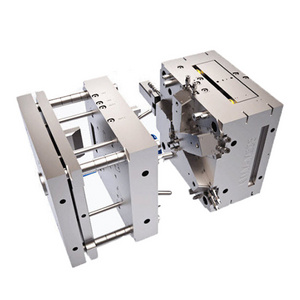

2. It can widely apply to automotive,injection mould,ironware mould and engrave mould industries.

3. Especially designed for 4D engraving and milling molds,eyeglasses, watch,panel,badge,brand, graphics and words and outside surface's sleeking of large size.

|

Description

|

Parameter

|

|

Working area

|

600*600*200mm

|

|

Control system

|

Mach 3 / NC studio

|

|

Table Surface

|

T-slot table

|

|

Drive Mechanism

|

Table moved

|

|

Spindle Motor

|

3.2KW water-cooling spindle(4.5/6.0kw for option)

|

|

Spindle speed

|

0~24000RPM

|

|

Machine frame

|

Cast by iron

|

|

Motor Drive

|

Leadshine hybrid servo driver and motor

|

|

Accuracy

|

0.01/300mm

|

|

Electrical components

|

Schneider

|

|

Inverter

|

Fuling

|

|

Software Compatibility

|

type3 or Wentai, ARTCAM/CAXA

|

|

Square rails

|

HIWIN

|

|

Working Voltage

|

AC220/380V;50/60Hz

|

|

X,Y,Z Structure

|

TBI Ball Screw

|

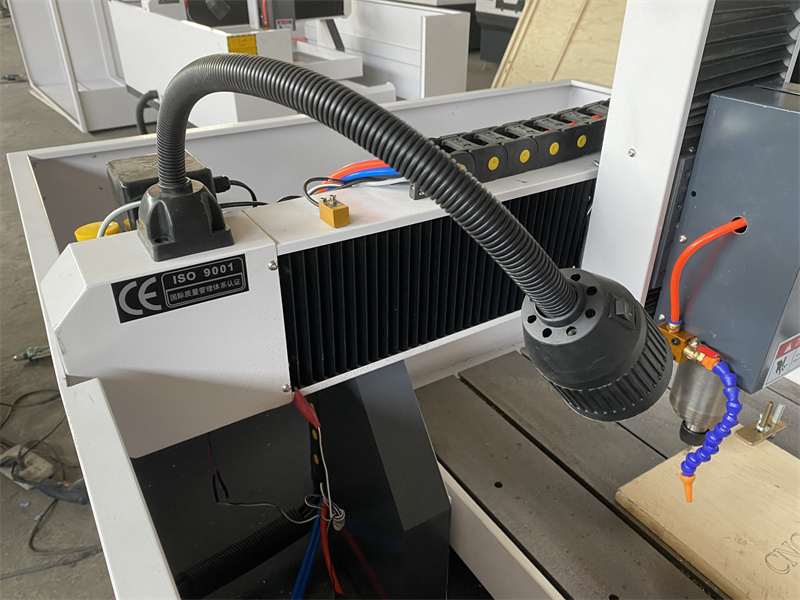

Parts

Features:

1. Integral cast-iron frame, equipping with double-screw auto eliminating clearance ball screw,floor-type linear guide transmission that can load heavy-duty board but never out of shape and ensure working precision.

2. High power water-cooling brushless inverter spindle motor, strongly cutting and durable.

3. High speed driver and stepper motor improve work efficiency.

4. Special dust-proof and waterproof device prevent dust and rust, and make it easier to maintain.

5. The machine aggregates advanced technique in CNC industry, with more than 10pcs break-point memory that can reduce waste materials.

6. High compatibility, applicable to CNC software such as type3,Art cam,Casemate,Pore, Wen tai and various CAD/CAM software..It is easy to process embossment,shadow engraving and three dimensional characters.

7. Special water-cooling system ensures the cutter a long life.

1. Integral cast-iron frame, equipping with double-screw auto eliminating clearance ball screw,floor-type linear guide transmission that can load heavy-duty board but never out of shape and ensure working precision.

2. High power water-cooling brushless inverter spindle motor, strongly cutting and durable.

3. High speed driver and stepper motor improve work efficiency.

4. Special dust-proof and waterproof device prevent dust and rust, and make it easier to maintain.

5. The machine aggregates advanced technique in CNC industry, with more than 10pcs break-point memory that can reduce waste materials.

6. High compatibility, applicable to CNC software such as type3,Art cam,Casemate,Pore, Wen tai and various CAD/CAM software..It is easy to process embossment,shadow engraving and three dimensional characters.

7. Special water-cooling system ensures the cutter a long life.

Rotary Axis working light

Back of machine

lubrication system

Water cooling spindle with Spray Schneider Electrical Component

Fulling inverter Iron table with sink

OMRON limit switch Tool sensor

Samples

Our Service

A Guarantee:

1. 24 months for the whole machine.

2. Within 24 months under normal use and maintenance,

If something is wrong with machine, you will get spare part for free.

3. Out of 24 months, you will get spare part at cost price.

4. You will also get technical support and service all the lifetime.

B Technical support:

1, Technical support by phone, email or MSN/Skype 24 HOURS.

2, Friendly English version manual and operation video CD disk.

3, Engineer available to service machinery overseas.

C After sales services:

1 Normal machine is properly adjusted before dispatch.

2 You will be able to use the machines immediately.

3 You will be able to get free training advice towards our machine in our factory.

4 You will also get free suggestion and consulting, technical support and service by email/fax/tel and lifetime technical support.

1. 24 months for the whole machine.

2. Within 24 months under normal use and maintenance,

If something is wrong with machine, you will get spare part for free.

3. Out of 24 months, you will get spare part at cost price.

4. You will also get technical support and service all the lifetime.

B Technical support:

1, Technical support by phone, email or MSN/Skype 24 HOURS.

2, Friendly English version manual and operation video CD disk.

3, Engineer available to service machinery overseas.

C After sales services:

1 Normal machine is properly adjusted before dispatch.

2 You will be able to use the machines immediately.

3 You will be able to get free training advice towards our machine in our factory.

4 You will also get free suggestion and consulting, technical support and service by email/fax/tel and lifetime technical support.

Packing and shipping

Hot Searches