- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PN630

-

Pay off bobbin:

-

PN630-PN1250

-

Width of bobbin:

-

400~950mm

-

Max diameter of the cable:

-

20

-

Pay off speed:

-

120m/min

-

Pay off motor:

-

5.5kW AC variable frequency motor (Siemens)

-

pay off control:

-

Siemens G120 series AC driver

-

Traversing motor:

-

BWED110-35x17-0.55KW (AC)

-

Clamp motor:

-

Y90L-6-B5-0.75KW, 960RPM (AC)

-

Lifting motor:

-

BLD10-43-0.55KW(AC 2 sets)

-

Control system:

-

Siemens PLC S7-200 Smart + Siemens Smart 7 inch touch screen.

Quick Details

-

Use:

-

wire and cable

-

Place of Origin:

-

China

-

Brand Name:

-

shineworld

-

Model Number:

-

PN630

-

Pay off bobbin:

-

PN630-PN1250

-

Width of bobbin:

-

400~950mm

-

Max diameter of the cable:

-

20

-

Pay off speed:

-

120m/min

-

Pay off motor:

-

5.5kW AC variable frequency motor (Siemens)

-

pay off control:

-

Siemens G120 series AC driver

-

Traversing motor:

-

BWED110-35x17-0.55KW (AC)

-

Clamp motor:

-

Y90L-6-B5-0.75KW, 960RPM (AC)

-

Lifting motor:

-

BLD10-43-0.55KW(AC 2 sets)

-

Control system:

-

Siemens PLC S7-200 Smart + Siemens Smart 7 inch touch screen.

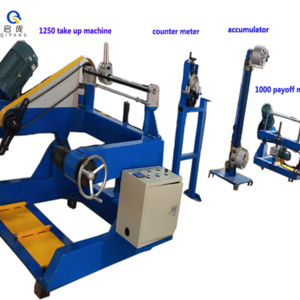

Products Description

P

ortal type pay-off stand,

ground rail walking passive, active pay-off machine and take-up line machine

Structural features of equipment

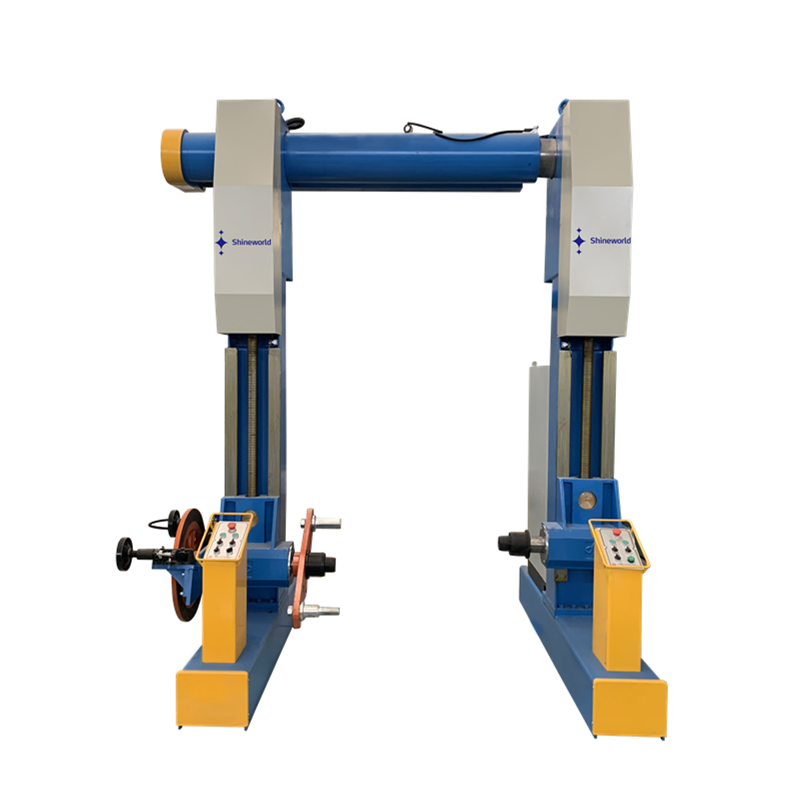

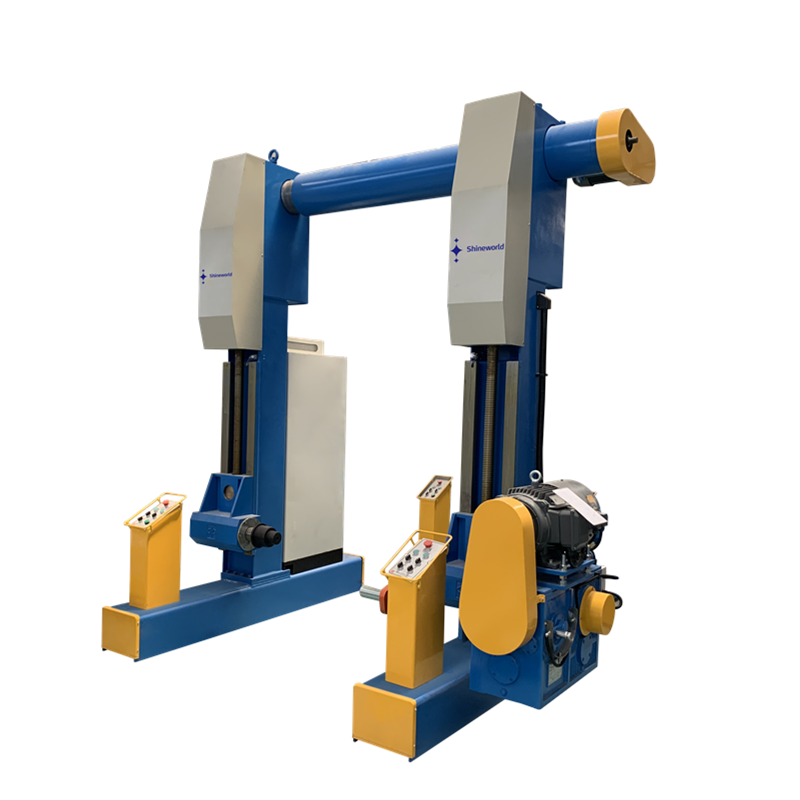

The machine is of gantry traversing type with upper-mounted casing-pipe. The gantry frame is made by bending and welding. The two tail-centers of wire reel are moved up/down by feed screw nut driven by two motors via cycloid speed reducer. Each tail-block can move by itself, or the center-blocks can move simultaneously. Double protective device is also equipped. When necessary, it can also be equipped with tail spindles for wire reels with various specifications. The clamping of wire reel is realized by the motor driving the reducer with overload protection.

The pay off motor adopt 5.5kw AC variable frequency motor, which drives the main shaft of the reel to rotate through the gearbox. The pay off motor is controlled by Siemens G120 series controller, the motor + cycloid reducer is used for driving, and the tension control of pay off is realized by torque or speed.

Siemens PLC S7-200 is used to manage the whole machine, providing the connection channel and relevant signals with the main control system.

|

Pay off bobbin

|

Width of bobbin

|

Max diameter of the cable

|

Pay off speed

|

Loading weight

|

|

PN630-1250

|

400~950mm

|

Φ20mm

|

120m/min

|

2T(max)

|

|

PN800-1600

|

600-1180mm

|

Φ40mm

|

80m/min

|

4T(Max)

|

|

PN1000-PN2000

|

750~1500mm

|

Φ60mm

|

80m/min

|

8T(max)

|

|

PN1250-PN2500

|

950~1900mm

|

Φ80mm

|

80m/min

|

12T(max)

|

|

PN1600-PN3150

|

1180~2300mm

|

Φ120mm

|

50m/min

|

18T(max)

|

Model Specification

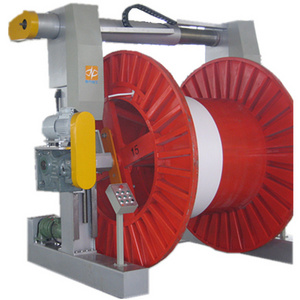

Swing arm type pay-off rack

End shaft pay-off stand

Frame type pay-off rack

Gantry pay-off rack

Why Choose Us

17 YEARS OF EXPERIENCE

★ Customers and markets all over the world

★

Products covering the entire cable industry

★

The most advanced technology

★

The most competitive price

★

The most cost-effective project solution

CUSTOMER FIRST, SERVICE FIRST

SHINEWORLD has offices in

Pakistan

,

Nigeria

and

Saudi Arabia

; and other countries will continue to establish.

Online debugging

Customer service and engineers are online 24 hours a day. Online communication, remote assistance, solve customer problems at any time.

Engineer dispatch

When the problem cannot be solved online, we will dispatch engineer to go abroad to solve the problem on-site for the customer.

Hot Searches