- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380-460v 3 phases

-

Power:

-

37kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

1000

-

Product Name:

-

Rotary Dryer for Organic Fertilizer

-

Model:

-

TDHG-2020

-

Main motor power:

-

37kw

-

Reducer model:

-

ZQ500

-

Intake temperature:

-

More than 300 degree

-

Installation angle:

-

3-5 degree

-

Rotary speed:

-

5.5r/min

-

Output:

-

8-15t/h

-

Thickness of the drum:

-

14mm

-

Dimension:

-

2000*20000mm

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Tongda

-

Voltage:

-

380-460v 3 phases

-

Power:

-

37kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

1000

-

Product Name:

-

Rotary Dryer for Organic Fertilizer

-

Model:

-

TDHG-2020

-

Main motor power:

-

37kw

-

Reducer model:

-

ZQ500

-

Intake temperature:

-

More than 300 degree

-

Installation angle:

-

3-5 degree

-

Rotary speed:

-

5.5r/min

-

Output:

-

8-15t/h

-

Thickness of the drum:

-

14mm

-

Dimension:

-

2000*20000mm

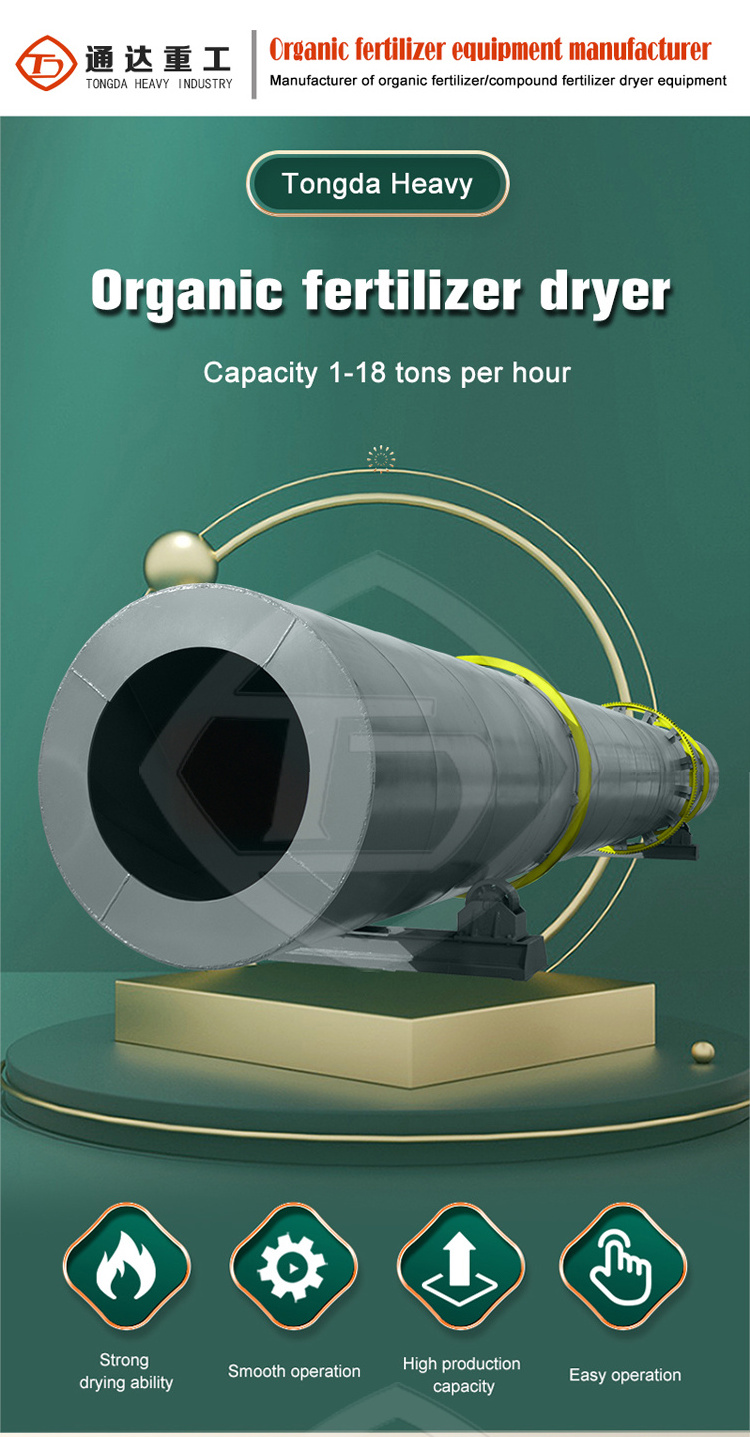

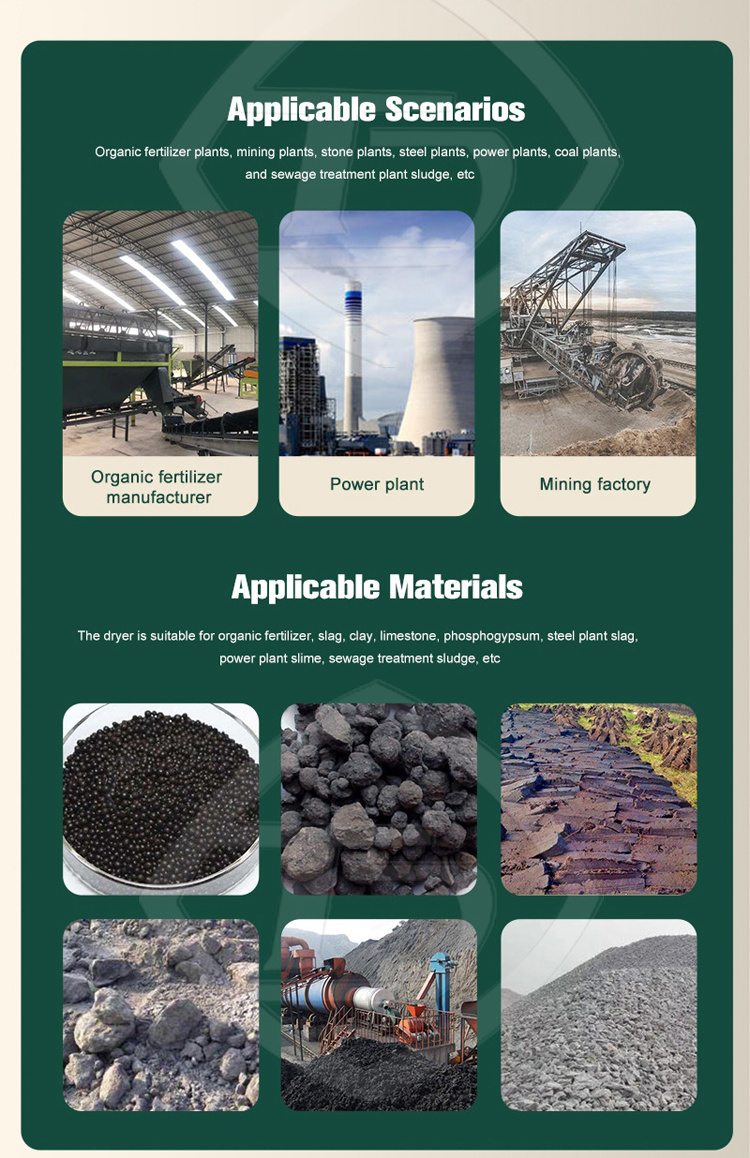

Rotary Dryer for Organic Fertilizer is suitable for drying organic fertilizer, slag, clay, limestine, phosphogypsum, steel slag, power plant sludge and sewage treatment plant sludge. It has the advantages of large drying capacity, stable operation, low energy consumption, easy operation and high output.

| Model |

Power (kw) |

Reducer Model |

Intake Temperature (degree) |

Installation Angle (degree) |

Rotary Speed (r/min) |

Output (t/h) |

| TDHG-0808 | 5.5 | ZQ250 | above 300 | 3-5 | 6 | 1-2 |

| TDHG-1010 | 7.5 | ZQ350 | above 300 | 3-5 | 6 | 2-4 |

| TDHG-1212 | 7.5 | ZQ350 | above 300 | 3-5 | 6 | 3-5 |

| TDHG-1515 | 11 | ZQ400 | above 300 | 3-5 | 6 | 4-6 |

| TDHG-1616 | 15 | ZQ400 | above 300 | 3-5 | 6 | 6-8 |

| TDHG-1818 | 22 | ZQ500 | above 300 | 3-5 | 5.8 | 7-12 |

| TDHG-2020 | 37 | ZQ500 | above 300 | 3-5 | 5.5 | 8-15 |

| TDHG-2222 | 37 | ZQ500 | above 300 | 3-5 | 5.5 | 8-16 |

| TDHG-2424 | 45 | ZQ650 | above 300 | 3-5 | 5.2 | 14-18 |

Features:

1. The cylinder of the dryer is a 14mm thick integrally formed spiral tube, which has the advantages of high concentricity and stable operation of steel. The thickness of the lifting plate is 5mm.

2. The ring gear, roller belt idler and bracket are all steel castings.

3. Adopting the downstream drying mode, the material and the heat source flow enter the drying equipment from the same side, and the outlet temperature of the dryer is low and the heat efficiency is high.

4. Select reasonable operating parameters to balance the “coal, feed, and wind”, thereby greatly improving the thermal efficiency of the dryer and reducing the drying energy consumption by 30-50%.

5. The cylinder adopts spiral tube, and the steel factory directly uses the same plate to weld into a bobbin to prevent deformation in the later stage; convenient transportation is divided into two sections, and the intermediate flange connection with gold processing self-deduction ensures tight integration.

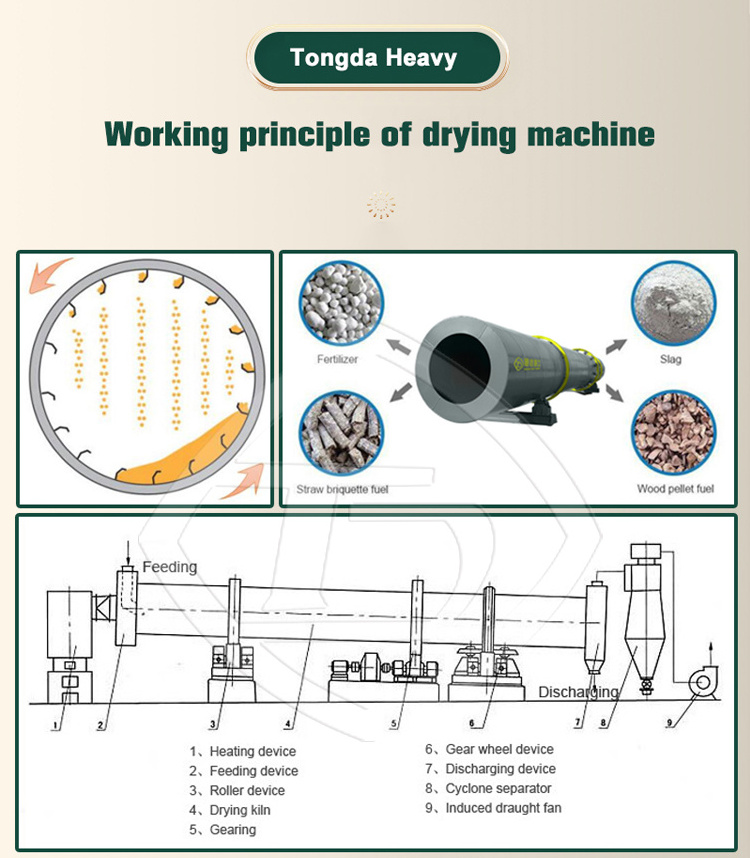

Working principle of drum dryer:

The material enters the inner layer of the rotary drum through the feeding device to achieve downstream drying. The material is continuously picked up and scattered under the inner plate in a spiral motion to achieve heat exchange. The material moves to the other end of the inner layer and enters the middle layer for countercurrent drying. The material is continuously lifted back and forth in the middle layer, in a two-step and one-step walking mode. The material fully absorbs the heat emitted by the inner drum and also absorbs the heat of the middle drum in the middle layer, At the same time, the drying time is extended, and the material reaches a good drying state here. The material travels to the other end of the middle layer and falls into the outer layer. The material travels in a rectangular multi loop manner inside the outer drum. The material that achieves the drying effect quickly moves and is discharged from the drum under the action of hot air. Wet materials that do not achieve the drying effect cannot move quickly due to their own weight. The material is fully dried in this rectangular board to achieve the drying purpose.