- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

20-30

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.15 - 2 mm

-

Heating Power (kW):

-

54 kW

-

Air Comsumption(L/min):

-

1.6 L/min

-

Water Comsumption(L/min):

-

0.1 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HUA XIANG

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

L3.5*W1.35H2.1 m

-

Weight (T):

-

5 T

-

Power(KW):

-

60

-

Application:

-

Lids

-

Finished Products:

-

Disposable Plastic Fast Food Box

-

Product name:

-

Plastic Cup Making Machine

-

Machine Name:

-

Automatic Plastic Cup Forming Machine

-

Suitable material:

-

PP PS PET PVC

-

Type:

-

Automatic High Speed Thermoforming Machine

-

Name:

-

Vacuum Thermoforming Making Machine

-

Usage:

-

Making PP PS Containers

-

Products:

-

Tableware Product

-

Power(W):

-

65-70kW

Quick Details

-

Max.Forming Height(mm):

-

170 mm

-

Forming Width (mm):

-

650 mm

-

Forming Length (mm):

-

320 mm

-

Production Speed(Cycles/min):

-

20-30

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.15 - 2 mm

-

Heating Power (kW):

-

54 kW

-

Air Comsumption(L/min):

-

1.6 L/min

-

Water Comsumption(L/min):

-

0.1 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HUA XIANG

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

L3.5*W1.35H2.1 m

-

Weight (T):

-

5 T

-

Power(KW):

-

60

-

Application:

-

Lids

-

Finished Products:

-

Disposable Plastic Fast Food Box

-

Product name:

-

Plastic Cup Making Machine

-

Machine Name:

-

Automatic Plastic Cup Forming Machine

-

Suitable material:

-

PP PS PET PVC

-

Type:

-

Automatic High Speed Thermoforming Machine

-

Name:

-

Vacuum Thermoforming Making Machine

-

Usage:

-

Making PP PS Containers

-

Products:

-

Tableware Product

-

Power(W):

-

65-70kW

HX-660/720/750 series Cup&container Making Machine

Description

HX-660 series Cup/Container Making Machine provides high production rates and quality finished products at a great price. Standard hydraulic and pneumatic control, Running stably and reliably, working life long, machine can keep working for 7*24

Application

This is a version of thermoforming, whereby a sheet of plastic is heated to a forming temperature, stretched onto a mold, and forced against the mold by air-pressure formed into permanent objects.

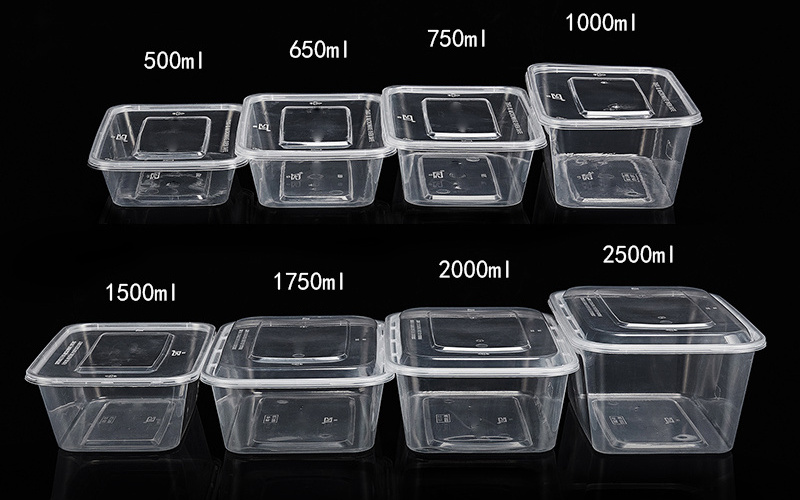

Primarily the manufacture of disposable cups, containers, lids, trays, blisters, clamshells, and other products for the food and general retail industries.

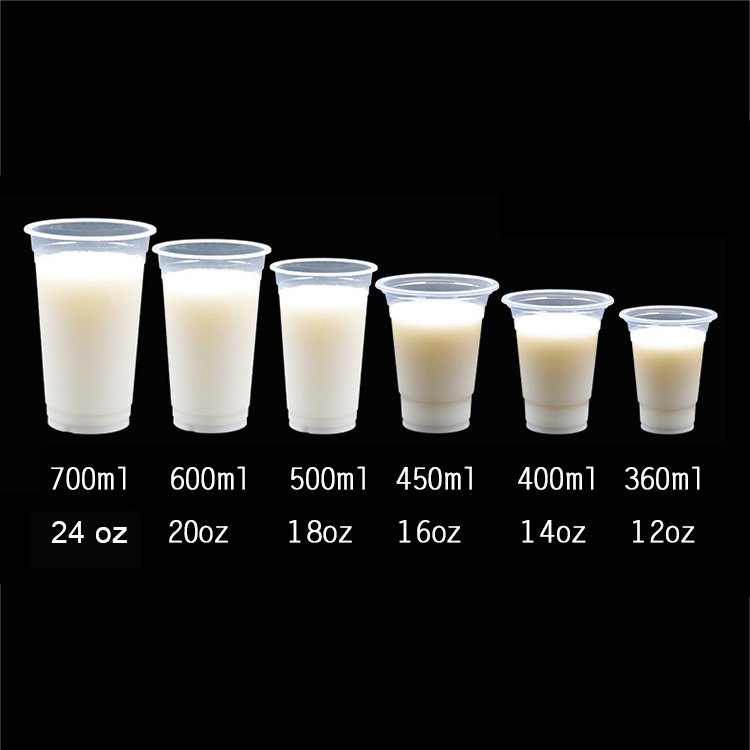

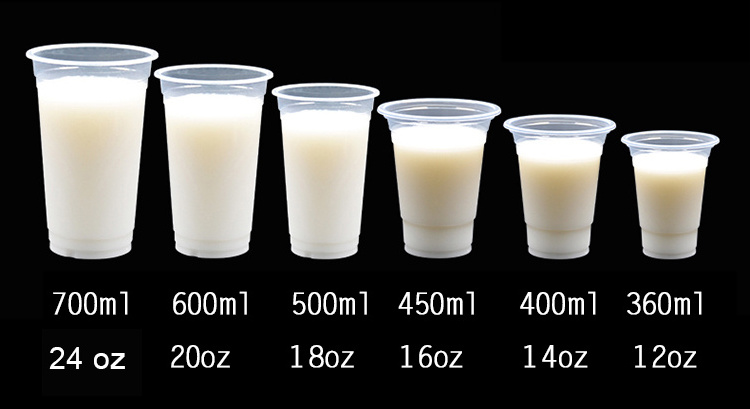

Sample

Parameter

|

Model |

HX-660 |

|

Material / Reel Feed |

PP ,PE,PET,HIPS,GPPS |

|

Forming Size (mm) |

620*260 |

|

Material Width (mm) |

500-660 |

|

Material Length (mm) |

0.3-2.0 |

|

Forming Height (mm) |

150 |

|

Forming Speed (Cycles/min) |

≤ 18-2 8 |

|

Heater Power (KW) |

100 |

|

Actual power consumption (Kw/h) |

70 |

|

Motor Power (kw) |

7.5 |

|

Air Requirements (Mpa) |

0.6-0.8 |

|

Water Requirements (L/min) |

3 |

|

Weight (Ton) |

5.5 |

|

Dimension Machine (L*W*H)(mm) |

Material feeder: 1000 ×700×550 Main machine: 3700 ×1360×2100 Scrap Winder : 600 ×900×480 Control cabinet: 1300 ×550×1900 |

Features

1. Pressure stable, powerful, high efficiency, energy conservation.

2.14-section heating zone with automatic temperature control, reasonable regional distribution of each section, homogeneous heating and easy to operate

3. Wide application, lower nose, reliable performance

4. Motor with overcurrent protection device.

5. Siemens PLC control

6. Equipment with asynchronous Scrap Winder, Roll diameter max 0.8m, easy to operation

7. High quality electrical and electronic components (SIEMENS, OMRON, SCHNEIDER)

8. Electrical cabinet and installation to CE standard

9. EAC certificate.

Chains and Rails

Heating system

Forming Station

Mold:

Composite structure, multifunction (air compression, forming, in-mould cutting, take-off)

Production packing line

Factory info

HUAXIANG is a diversified export-oriented enterprise integrated with technology, industry and trade. established in 2005, is the professional enterprise that specializ in the production of Vacuum Forming/Thermoforming Machine. Our machine are used a lot in plastic forming,plastic packaging field;

more about us please click our website

https://huaxiangjx.en.alibaba.com/

Welcome to inquiry us

In order to help you choose the most suitable machine, please try to reply my questions below, thanks for your cooperation

.

Q1: What about your material?

Q2: The size of your sample; length, width and thickness?