- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

45

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Chemical Industry

-

Grade:

-

Ni,Cr

-

Ni (Min):

-

99.6%

-

Model Number:

-

ni200

-

Brand Name:

-

DLX

-

Surface:

-

Bright

-

Process method:

-

Drawing And Rolling

-

Treatment:

-

Hydrogen Annealing

-

pure nickel wire size:

-

0.025-10mm

-

Condition:

-

Soft Annealed

-

Certificate:

-

ISO,TUV

-

Density:

-

8.89 g/m3

-

Delivery Time:

-

7-20 Days

-

MOQ:

-

3kg

-

Melting Point(℃):

-

1435-1446

Quick Details

-

Resistance (μΩ.m):

-

1.5

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

462

-

Elongation (≥ %):

-

45

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Chemical Industry

-

Grade:

-

Ni,Cr

-

Ni (Min):

-

99.6%

-

Model Number:

-

ni200

-

Brand Name:

-

DLX

-

Surface:

-

Bright

-

Process method:

-

Drawing And Rolling

-

Treatment:

-

Hydrogen Annealing

-

pure nickel wire size:

-

0.025-10mm

-

Condition:

-

Soft Annealed

-

Certificate:

-

ISO,TUV

-

Density:

-

8.89 g/m3

-

Delivery Time:

-

7-20 Days

-

MOQ:

-

3kg

-

Melting Point(℃):

-

1435-1446

Products Description

Ultrathin Pure nickel wire Ni200 0.025mm prices

Commercially pure wrought Nickel with good mechanical properties over a wide range of temperature and excellent resistance to many corrosives, in particular hydroxides.

Good resistance to corrosion in acids and alkalis and is most useful under reducing conditions. Outstanding resistance to caustic alkalis up to and including the molten state. In acid, alkaline and neutral salt solutions the material shows good resistance, but in oxidizing salt solutions severe attack will occur. Resistant to all dry gases at room temperature and in dry chlorine and hydrogen chloride may be used in temperatures up to 550C. Resistance to mineral acids varies according to temperature and concentration and whether the solution is aerated or not. Corrosion resistance is better in de-aerated acid.

Good resistance to corrosion in acids and alkalis and is most useful under reducing conditions. Outstanding resistance to caustic alkalis up to and including the molten state. In acid, alkaline and neutral salt solutions the material shows good resistance, but in oxidizing salt solutions severe attack will occur. Resistant to all dry gases at room temperature and in dry chlorine and hydrogen chloride may be used in temperatures up to 550C. Resistance to mineral acids varies according to temperature and concentration and whether the solution is aerated or not. Corrosion resistance is better in de-aerated acid.

Notes:

3. High melting point.

4. With good weldability.

5. Low electrical resisitivity.

6. Electrical conductivity.

NUS N02201 (ASTM B 162) same as N4 (GB/T 2054).

NUS N02200 (ASTM B 162) same as N6 (GB/T 2054).

NUS N02200 (ASTM B 162) same as N6 (GB/T 2054).

Features:

1. Nickel has good mechanical strength and ductility.

2. Excellent performance on corrosion-resistance.

1. Nickel has good mechanical strength and ductility.

3. High melting point.

4. With good weldability.

5. Low electrical resisitivity.

6. Electrical conductivity.

Functions/Applications

1.

Used in vacuum device .

2. Electronic instrument component.

3. Filter screen which is used to filter the strong acid and alkali.

4. Electric light / Electric light source.

5. Chemical Industry.

6. Electronic cigarette heating wire.

2. Electronic instrument component.

3. Filter screen which is used to filter the strong acid and alkali.

4. Electric light / Electric light source.

5. Chemical Industry.

6. Electronic cigarette heating wire.

|

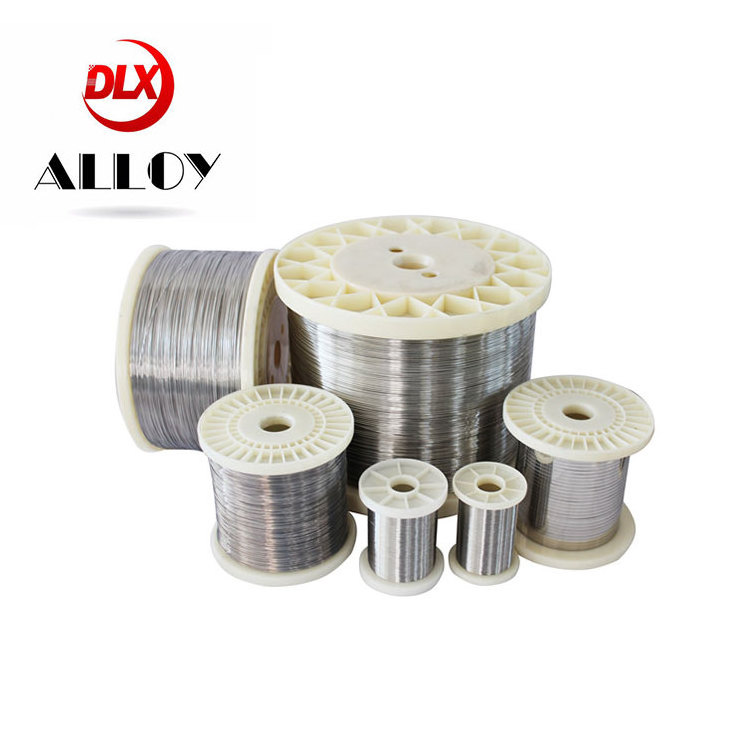

Size Range

|

|

|

|

Wire

|

dia 0.025-10mm

|

|

|

|

|

|

|

Ribbon

|

(0.05-0.2)*(0.5-6.0)mm

|

|

|

|

|

|

|

Strip

|

(0.05-0.5)*(5-200)mm

|

|

|

|

|

|

|

Plate

|

custom made

|

|

|

Density

|

8.89 g/cm3

|

|

Tensile Strength ksi (min)

|

462

|

|

Yield Strength 0.2% ksi (min)

|

148

|

|

Elongation δ5 (%)

|

40

|

|

Melting point

|

1435-1446°C

|

Specification

|

Grade

|

Ni+Co

|

Cu

|

Si

|

Mn

|

C

|

Mg

|

S

|

P

|

Fe

|

|

N4

|

99.8

|

0.015

|

0.03

|

0.002

|

0.01

|

0.01

|

0.001

|

0.001

|

0.04

|

|

N6

|

99.6

|

0.10

|

0.10

|

0.05

|

0.10

|

0.10

|

0.005

|

0.002

|

0.10

|

|

Ni201

|

≥99.0

|

≤0.25

|

≤0.35

|

≤0.35

|

≤0.02

|

/

|

≤0.01

|

/

|

≤0.40

|

|

Ni200

|

≥99.2

|

≤0.25

|

≤0.35

|

≤0.35

|

≤0.15

|

/

|

≤0.01

|

/

|

≤0.40

|

Recommend Products

About Us

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Customized service

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

What's your contact information?

Mobile/Wechat/Whatsapp: +8618018210953

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Hot Searches