- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4*3*2.4m

-

Year:

-

2022

-

Power (kW):

-

268 kW

-

Weight (KG):

-

30000 KG

-

Applicable Industries:

-

Tire Recycling

-

End product:

-

Rubber Particle/Rubber Powder

-

Capacity:

-

500-10000kg/h

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4*3*2.4m

-

Year:

-

2022

-

Power (kW):

-

268 kW

-

Weight (KG):

-

30000 KG

-

Applicable Industries:

-

Tire Recycling

-

End product:

-

Rubber Particle/Rubber Powder

-

Capacity:

-

500-10000kg/h

|

Technical Parameters

|

|

|

|

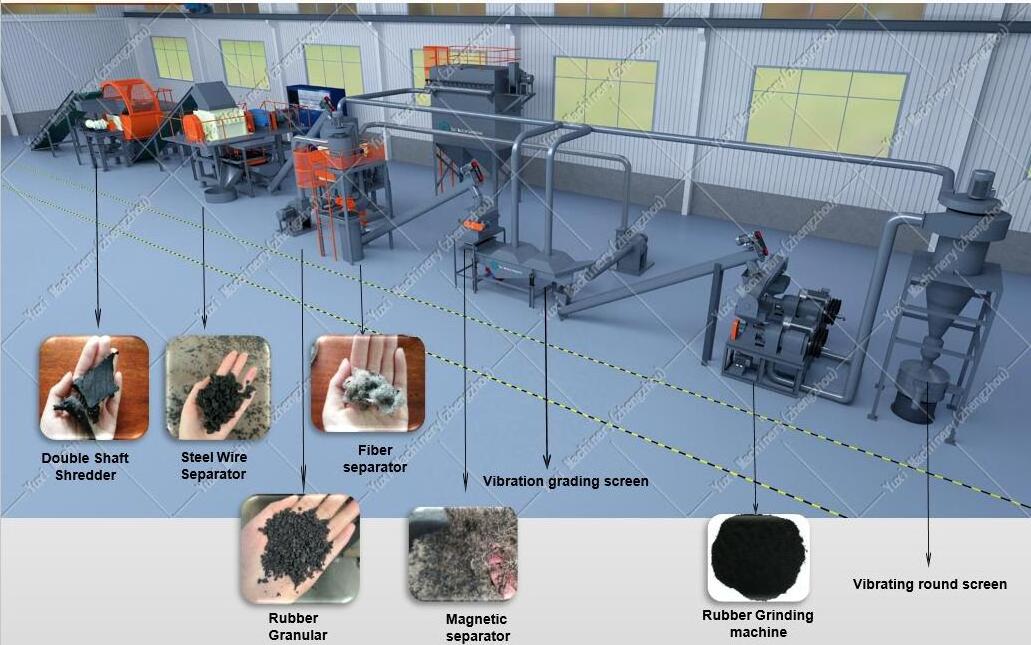

Capacity

|

500-10000kg/h

|

|

|

Scope of application

|

Diameter of the tire: 400-3000mm

|

|

|

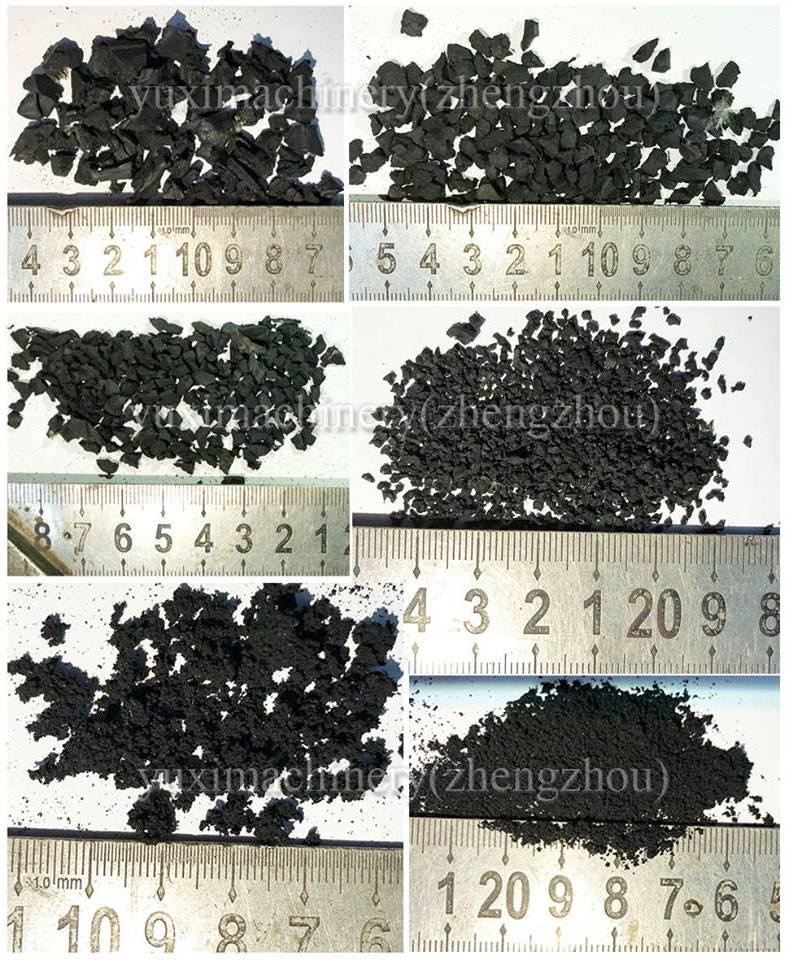

Output size

|

5-100mesh, can be Customized

|

|

|

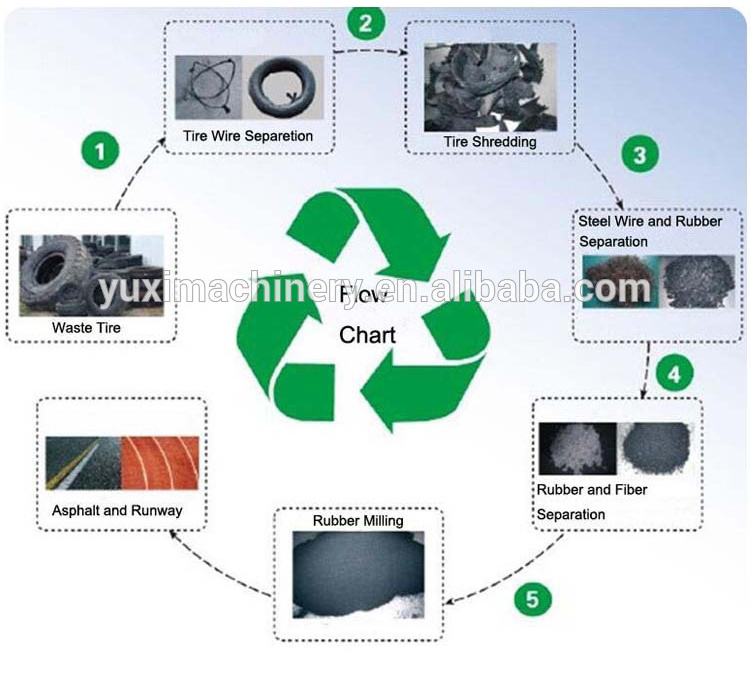

Complete separation

|

The rubber crumbs, steel and fibre can be separated automatically.

Adopt PLC control system, it is simple and easy to control and maintain. For example, it is only need 4-6persons to operate a tire recycling(granule) production line with 3000kg/h capacity. Low energy consumption. the installed power of tire recycling production (granule) line with capacity 3000kg/h is about 800kw. |

|

|

Equipment required area

|

About 680square meter, 7m height

|

|

|

Characteristic of blade

|

Long service life, high utilization, multiple maintenance

|

|

What Is The Application of Used Tires?

Q:

How about price?

A:

We are factory and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

Q:

When we only building one shredder machine production line, can we use it to shred wood

material or waste metal material?

A:

Yes, you can. It depends on the difference of blades teeth and quantity.Can be customized.

Q:

What is the difference between your machine and others’?

A:

Every machine is unique, We can help you decide your unique situation and decide which tool is right for your job.

Q:

Will you dispatch the engineer to guide installation the high output shredder equipment ?

A:

Yes, according to the customer’s requirement, we will dispatch the engineer to guide installation the high output shredder equipment .

Q:

How about you to ensure the shredder machine equipment normal running?

A:

Except the installation engineer, we also provide the production engineer to guide how to keep a good production.