- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

EddaAir

-

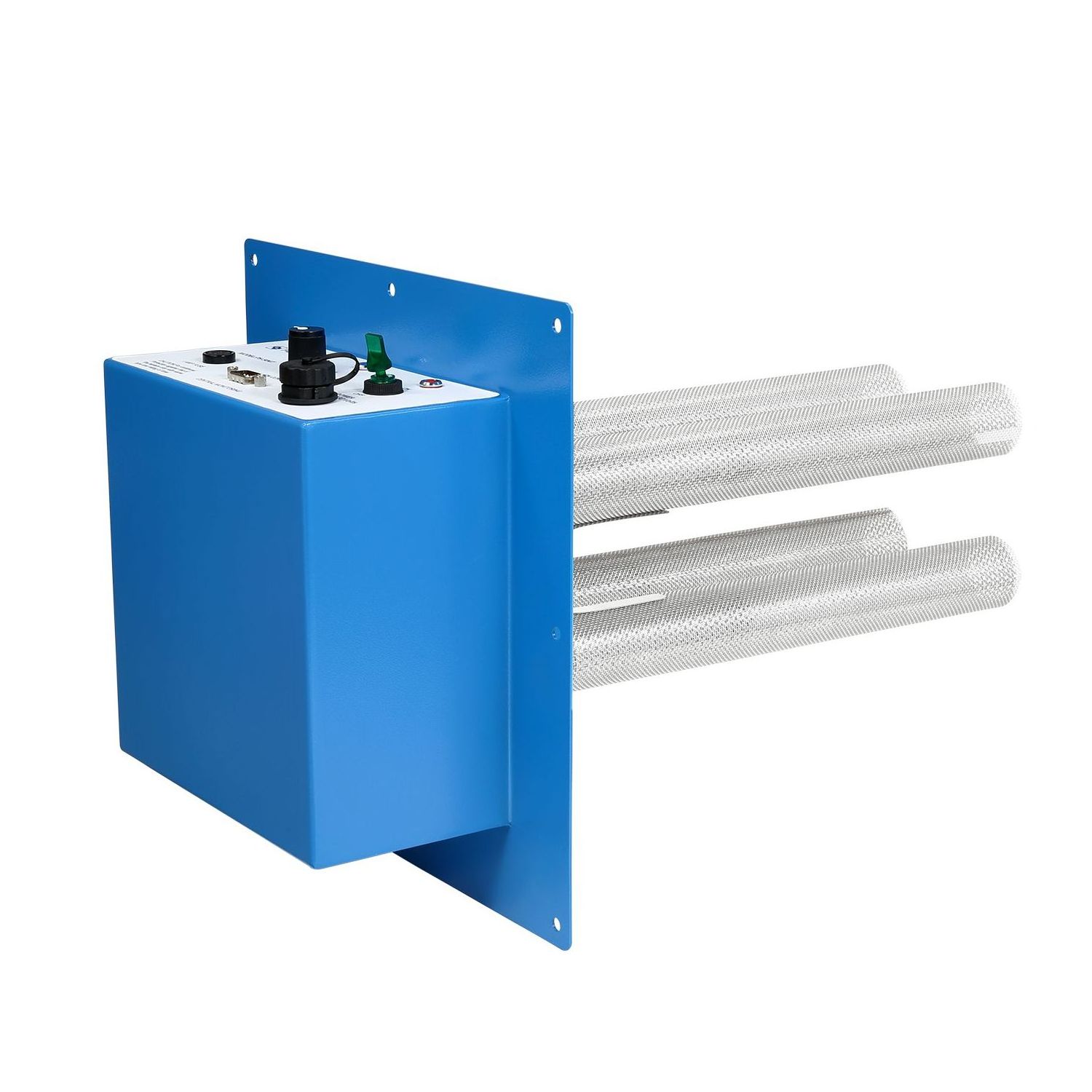

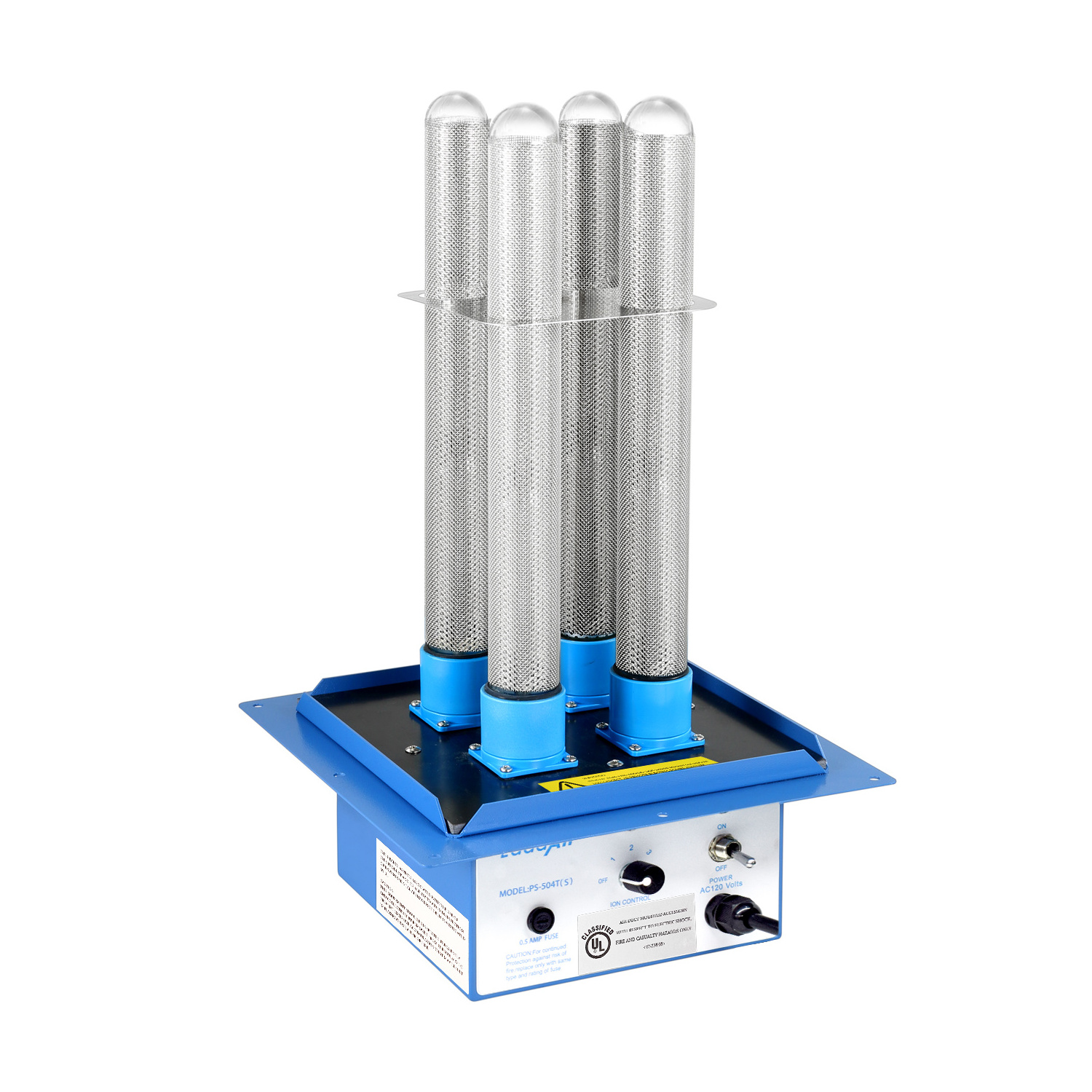

Product name:

-

Bipolar ionization technology for Livestock Keeping deodorization

-

Noise:

-

<20db

-

Material:

-

SPCC

-

Certification:

-

CB TUV FC UL CE ISO9001

-

Voltage:

-

AC 110V / 220V

-

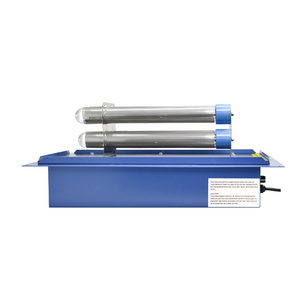

Dimension:

-

545*282*230mm

-

Capacity (CFM):

-

6500CMF/11000m³/h

-

Power (W):

-

20

-

Tube size:

-

350mm(14inch)

-

Coverage area:

-

400m2

Quick Details

-

Weight (KG):

-

5.8

-

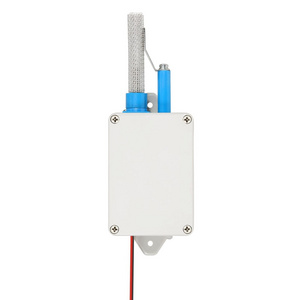

Core Components:

-

plasma air purifier

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

EddaAir

-

Product name:

-

Bipolar ionization technology for Livestock Keeping deodorization

-

Noise:

-

<20db

-

Material:

-

SPCC

-

Certification:

-

CB TUV FC UL CE ISO9001

-

Voltage:

-

AC 110V / 220V

-

Dimension:

-

545*282*230mm

-

Capacity (CFM):

-

6500CMF/11000m³/h

-

Power (W):

-

20

-

Tube size:

-

350mm(14inch)

-

Coverage area:

-

400m2

Product Description

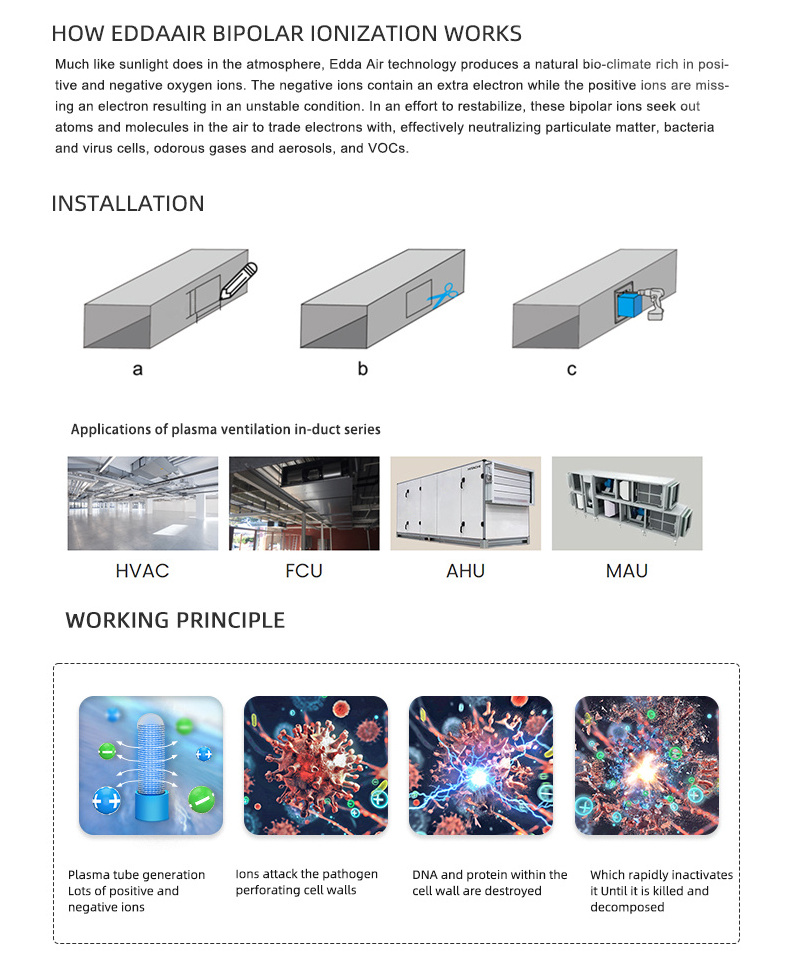

Food technology has reached new levels of innovation in the effort to ensure product safety, driven by consumer demands and government regulations to produce “bacteria-free” foods. Consumers are seeking more nutritious, less processed foods, while simultaneously expecting “bacteria-free” products of high quality and long shelf life.

Food safety bipolar ionization technologies used in the meat industry encompass many areas of manufacturing. These include slaughter, meat product fabrication (e.g., cutting, blending and extruding),

poultry processing,

further processing (e.g., cooking, curing, drying and freezing) and packaging,

including in-line disinfection for food contact surfaces (e.g., feeder lines, cutting blades, conveyor belts),

Studies have shown that plasma discharges can be used to decontaminate raw produce, dried nuts, meat, poultry, fish, granular foods (i.e. dried milk, herbs, and spices), processing equipment, and packaging materials.

PLASMA TECHNOLOGY IS EMERGING AS THE NEW STANDARD IN FOOD SAFETY TECHNOLOGY:

* Plasma Technology in the Meat Industry (Food Safety Magazine)

* New technologies: Cold plasma (Campden BRI)

* Plasma for the Food Industry (Institute of Food Science Technology)

* Plasma Technology in the Meat Industry (Food Safety Magazine)

* New technologies: Cold plasma (Campden BRI)

* Plasma for the Food Industry (Institute of Food Science Technology)

Specification

|

Brand

|

EddaAir(PS-501T4)H

|

|

Air volume

|

6500CFM/11000m³/h

|

|

Applicable area

|

400m²

|

|

After-sales Service Provided

|

Free spare parts, Return and Replacement

|

|

Warranty

|

1 Year

|

|

Application

|

growing indoor,Animal Farm, hotel,Hotel, warehouse, toilet, school, commercial room,food processing plants,food preservation,

|

|

Weight

|

8KG

|

|

Voltage

|

AC110V/AC220V

|

|

Power

|

20W

|

|

Working Noise

|

20dB

|

|

Material

|

SPCC

|

|

Ion Tube Size

|

545*280*230mm

|

|

Ion Tube Quantity

|

4

|

|

Ion Tube Lifespan

|

17000H

|

|

Frequency

|

50-60Hz

|

The belowing certificates will increase your confidence in our products.

Many clients use our products and achieve their targets!

Application case

Plasma technology, particularly non-thermal or cold plasma,

some potential advantages:

1. Microbial Decontamination:

* Plasma technology can be effective in reducing or eliminating harmful microorganisms on the surface of meat products. This includes bacteria such as Salmonella and E. coli. The non-thermal nature of the plasma treatment helps in preserving the quality of the meat.

* Plasma technology can be effective in reducing or eliminating harmful microorganisms on the surface of meat products. This includes bacteria such as Salmonella and E. coli. The non-thermal nature of the plasma treatment helps in preserving the quality of the meat.

2. Extended Shelf Life:

* Plasma treatment can contribute to extending the shelf life of meat products by reducing the microbial load. This can

result in decreased spoilage and improved overall product quality and safety.

3. Preservation of Nutritional Value:

* Non-thermal plasma treatment is gentle and does not subject the meat to high temperatures, helping to preserve the

nutritional content, color, and texture of the meat.

result in decreased spoilage and improved overall product quality and safety.

3. Preservation of Nutritional Value:

* Non-thermal plasma treatment is gentle and does not subject the meat to high temperatures, helping to preserve the

nutritional content, color, and texture of the meat.

4. Reduced Chemical Additives:

* By providing an effective microbial decontamination method, plasma technology may reduce the dependence on chemical additives and preservatives in the meat processing industry, contributing to cleaner and more natural products.

5. Customization of Surface Properties:

* Plasma treatment allows for the modification of surface properties, such as wettability and adhesion. This can be advantageous for improving the binding of marinades or coatings, leading to enhanced flavor and texture.

5. Customization of Surface Properties:

* Plasma treatment allows for the modification of surface properties, such as wettability and adhesion. This can be advantageous for improving the binding of marinades or coatings, leading to enhanced flavor and texture.

6. Environmental Benefits:

* Plasma technology often involves the use of gases like air, nitrogen, or other environmentally friendly substances. This

can align with the industry's increasing focus on sustainable and eco-friendly practices.

7. Reduced Energy Consumption:

* Compared to traditional thermal processes, plasma technology generally operates at lower temperatures, resulting in

potentially lower energy consumption during meat processing.

8. Selective Inactivation:

* Plasma technology can be selective in targeting harmful microorganisms while preserving desirable attributes of the meat.This selectivity can contribute to a more controlled and precise decontamination process.

* Plasma technology often involves the use of gases like air, nitrogen, or other environmentally friendly substances. This

can align with the industry's increasing focus on sustainable and eco-friendly practices.

7. Reduced Energy Consumption:

* Compared to traditional thermal processes, plasma technology generally operates at lower temperatures, resulting in

potentially lower energy consumption during meat processing.

8. Selective Inactivation:

* Plasma technology can be selective in targeting harmful microorganisms while preserving desirable attributes of the meat.This selectivity can contribute to a more controlled and precise decontamination process.

Build for you-Your One Stop Solutio

Hot Searches