Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tongsan

-

Voltage:

-

380V/50hz/3phase or customized

-

Dimension(L*W*H):

-

24,000 x 1,800 x 2,200mm

-

Weight:

-

10 KG

-

After-sales Service:

-

Engineers available to service machinery overseas

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Temperature control:

-

Omron Brand

-

Coiling mode:

-

auto double winder

-

Color:

-

Customised

-

Power:

-

30-120kw

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tongsan

-

Voltage:

-

380V/50hz/3phase or customized

-

Dimension(L*W*H):

-

24,000 x 1,800 x 2,200mm

-

Weight:

-

10 KG

-

After-sales Service:

-

Engineers available to service machinery overseas

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Temperature control:

-

Omron Brand

-

Coiling mode:

-

auto double winder

-

Color:

-

Customised

-

Power:

-

30-120kw

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Marketing Type:

-

Hot Product 2021

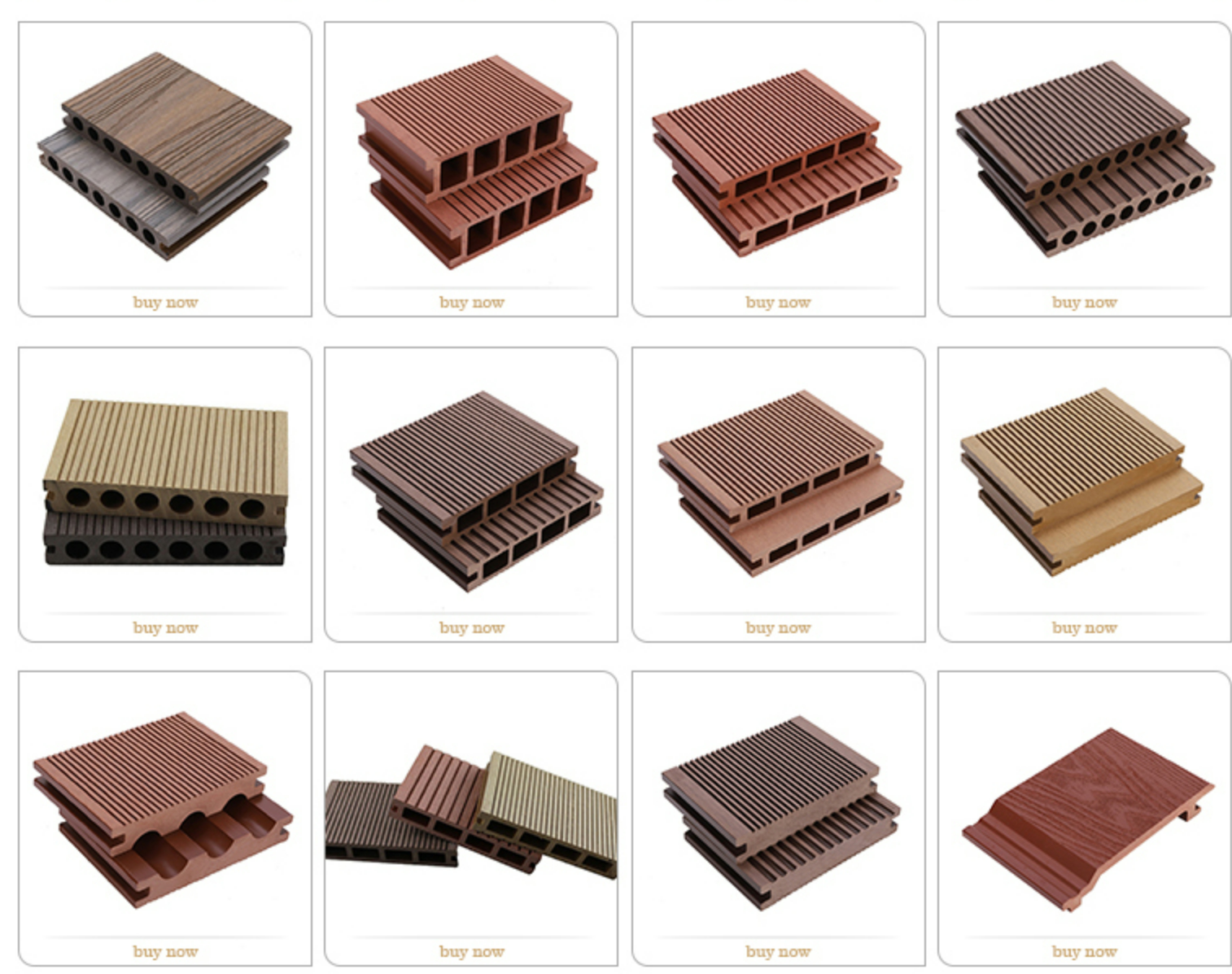

Material:

Wood powder ( waste wood brick,wood sawdust,rice husk,plant straw,etc)Plastic( Recycled PP/PE flake/granule,recycled PVC powder,orginal PVC powder)

Production proecss:

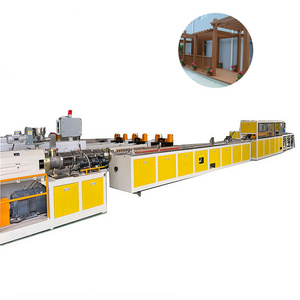

The final product application:

floor,decking,pallet,outdoor landscape architecture,fence,post,wall panel,door and window profile,etc.

By changing the moulds,the wood plastic compoite machine can produce vairous of profiles.

The mould can be customized by client's requirement.

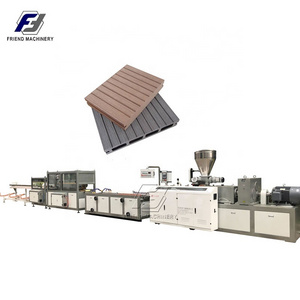

Main Features of WPC Machine

1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber.

2)With scientific and reasonable technology,the machine has high efficiency and runs stably

3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt.

4)This is one step WPC extrusion technology,which saves energy

5)This production line can produce wpc products of different specifications only to change mold.

6)Imported PLC automatic control.

|

Model

|

SJMS-51/105

|

SJMS-65/132

|

SJMS-80/156

|

SJ35/28

|

|

Max.product width

|

200mm

|

250mm

|

400mm

|

|

|

Extruder capacity

|

100-120kg/h

|

150-180kg/h

|

350-380kg/h

|

15kg/h

|

|

Main motor power

|

22kw

|

37kw

|

75kw

|

5.5kw

|

|

Vacuum pump power

|

3kw

|

7.5+5.5kw

|

11+7.5kw

|

|

|

Calibrating platform length

|

4000mm

|

6000m

|

6000m

|

|