- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.1kw

-

Min. Lifting Height:

-

1800mm

-

Table Size:

-

2270*1120mm

-

Overall Dimensions:

-

2480*1150*2470mm

-

Weight:

-

350 kg

-

Product name:

-

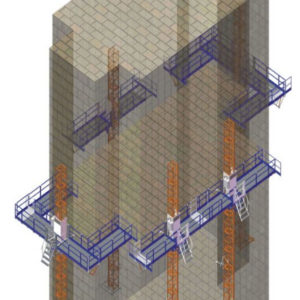

Hydraulic Platform Lift

-

Application:

-

Aerial Construction Work

-

Material:

-

Steel

-

Color:

-

Blue

-

Voltage:

-

110v 220v 240v 380v Optional

-

Load capacity:

-

300/500/1000/2000/3000kg

-

Lift Drive:

-

Hydraclic

-

Certification:

-

ISO CE

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DAAILIFT

-

Power:

-

1.1kw

-

Min. Lifting Height:

-

1800mm

-

Table Size:

-

2270*1120mm

-

Overall Dimensions:

-

2480*1150*2470mm

-

Weight:

-

350 kg

-

Product name:

-

Hydraulic Platform Lift

-

Application:

-

Aerial Construction Work

-

Material:

-

Steel

-

Color:

-

Blue

-

Voltage:

-

110v 220v 240v 380v Optional

-

Load capacity:

-

300/500/1000/2000/3000kg

-

Lift Drive:

-

Hydraclic

-

Certification:

-

ISO CE

1. The mast material is made of high-strength aviation aluminum to ensure the absolute safety of the operators.

2. The self-developed integral built-in sliding block is used between each mast, so that the dynamic gap between the masts is small, and it runs when lifting more stable and reliable, far better than ordinary independent guide wheel support structure;

3. The four-wheel rolling chassis is adopted on the site, which can walk easily even in corners and narrow and difficult areas.

4. The guardrail adopts lifting installation, and there are sliding bars between the guardrails, which is convenient for personnel to get on and off.

5. There is a spirit level on the chassis to easily ensure that the machine is in a horizontal position. Suction cup type leveling legs with level indicator are always platform provide solid and stable ground support, even on slightly uneven ground;

6. Adopt American Curtis dual control switch, the platform can be operated independently up and down

7. There is an emergency stop switch on the platform to prevent equipment failure and ensure the absolute safety of personnel

8. There is an emergency lowering device under the platform, even if the platform loses power accidentally, it can ensure that the platform descends slowly and relieve the operator the worries of the future, safer to use.

9. The 100% pilot valve controls the gap, which further improves the matching degree between the masts, so that the left and right shaking of the high-altitude platform is small.Technology meets EU CE standards

Problems that should paid attention to in the safe use of aluminum alloy lift

There may be some accidents during the use of aluminum alloy lifts. Only by taking precautions can we effectively prevent these accidents from happening. In the process of using the aluminum alloy elevator, we should always pay attention to whether the protective measures of the aluminum alloy elevator are operating normally, and find the problem and deal with it in time.

The following will introduce some safety protection devices of aluminum alloy lifts, and which ones need to be paid attention to whether they are running normally:

1. Anti-fall safety device for aluminum alloy lifting platform

The anti-fall safety device is an important part of the construction elevator. It is necessary to rely on it to eliminate the occurrence of cage falling accidents and ensure the safety of the occupants. Therefore, the factory test of the anti-fall safety device is very strict. Before leaving the factory, the legal inspection unit will measure its progress torque, the measurement at the critical speed, and the measurement of the spring compression. Each set is attached with a test report and assembled on the construction hoist. The drop test under the rated load is carried out later, and the lifts in use on the construction site must be subjected to a drop test every three months. For the anti-fall safety device that has been out of the factory for two years (the date of manufacture on the anti-fall safety device), it must also be sent to the statutory inspection unit for testing and testing, and then it will be tested once a year.

2. Safety switch of aerial work platform

The safety switches of the elevator are designed according to safety requirements, including fence door limit, hanging cage door limit, top door limit, limit switch, upper and lower limit switch, and anti-weight rope breaking protection switch. In some construction sites, in order to save trouble, some limit switches are artificially canceled and short-circuited or not repaired on time after damage, which is equivalent to canceling these safety lines of defense and planting hidden dangers.

3. Wear and replacement of gears and racks

The use of aluminum alloy elevators on the construction site, the operating environment is harsh, the cement, mortar, and dust cannot be eliminated and cleaned, and the gears and racks grind each other, and the teeth are sharpened and still in use, which should be paid attention to. The tooth profile should be like a cantilever beam, and when worn to a certain size, the gear (or rack) must be replaced. To what extent should you stop using it and replace it with a new one? A 25-50mm common normal micrometer can be used for measurement. When the common normal length of the gear is worn from 37.1mm to less than 35.1mm (2 teeth), a new gear must be replaced. When the rack is worn, measured by the tooth thickness caliper, when the tooth thickness is worn from 12.56mm to less than 10.6mm when the chord height is 8mm, the rack must be replaced.