Effectively shovel peanuts at a certain depth to loosen the soil.

- Product Details

- {{item.text}}

Quick Details

-

Row Distance(mm):

-

750 - 850 mm

-

Usage:

-

Peanut Harvester

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

usewell

-

Dimension(L*W*H):

-

2100*1100*900mm

-

Weight:

-

200 KG, 200 (kg)

-

Core Components:

-

Other

-

Product name:

-

Peanut Harvester

-

Keywords:

-

Vibrating screen peanut harvester

-

Applicable fields:

-

agriculture

-

Power type:

-

diesel power

-

Automation level:

-

Fully automatic

-

Total loss rate:

-

0.1%

-

Cutting amplitude:

-

80cm

-

External dimensions:

-

2100*1100*900(mm)

Quick Details

-

Number of Rows:

-

1

-

Working Width(mm):

-

800 mm

-

Tractor Power(HP):

-

18 - 32 HP

-

Row Distance(mm):

-

750 - 850 mm

-

Usage:

-

Peanut Harvester

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

usewell

-

Dimension(L*W*H):

-

2100*1100*900mm

-

Weight:

-

200 KG, 200 (kg)

-

Core Components:

-

Other

-

Product name:

-

Peanut Harvester

-

Keywords:

-

Vibrating screen peanut harvester

-

Applicable fields:

-

agriculture

-

Power type:

-

diesel power

-

Automation level:

-

Fully automatic

-

Total loss rate:

-

0.1%

-

Cutting amplitude:

-

80cm

-

External dimensions:

-

2100*1100*900(mm)

Products Description

Introduction Of

Tractor Mounted Small Peanut Harvesting Equipment Peanut Picker Combine Groundnut Harvester Machine

:

Peanut harvesting machine is a machine used for groundnut harvest, which can separate the peanuts growing in the soil from the soil. The peanut harvester completes peanut harvesting through the steps of digging, removing soil, and picking fruit. The problem of low labor efficiency is solved, and the peanut harvester can harvest 99% of the peanuts in the field.

|

Product name

|

Vibrating screen peanut harvester

|

|

|

|

|||

|

Transmission mode

|

Belt transmission, transmission shaft transmission

|

|

|

|

|||

|

Supporting power

|

17 horsepower and above diesel engine

|

|

|

|

|||

|

Work efficiency

|

1300-2000 square meters/hour

|

|

|

|

|||

|

Excavation depth

|

30cm

|

|

|

|

|||

|

Applicable soil quality

|

Sandy, semi sandy

|

|

|

|

|||

The peanut harvesting machine replaces the manual digging of peanut fruits, turns the peanuts out of the ground, and puts the dug-out peanut seedlings on the side of the machine, which is convenient to be pulled away directly by a car. The net recovery rate is greater than 99% and the peeling rate is less than 1%. After being processed by the peanut harvester, there are almost no peanuts in the world.

The peanut harvester needs to work with a 20-35 horsepower tractor. If you already have a tractor, you can directly use your own tractor. If not, we also have a matching tractor, you can choose to buy it. The row spacing of peanuts can be adjusted between 180-250mm. The working depth of the peanut harvester is 3-5cm. Applicable to one line and two lines. A peanut planter can be used in the peanut production industry after the peanuts are harvested if you can also use a peanut picking machine to pick the peanut fruit. This saves more time and effort.

Details Images

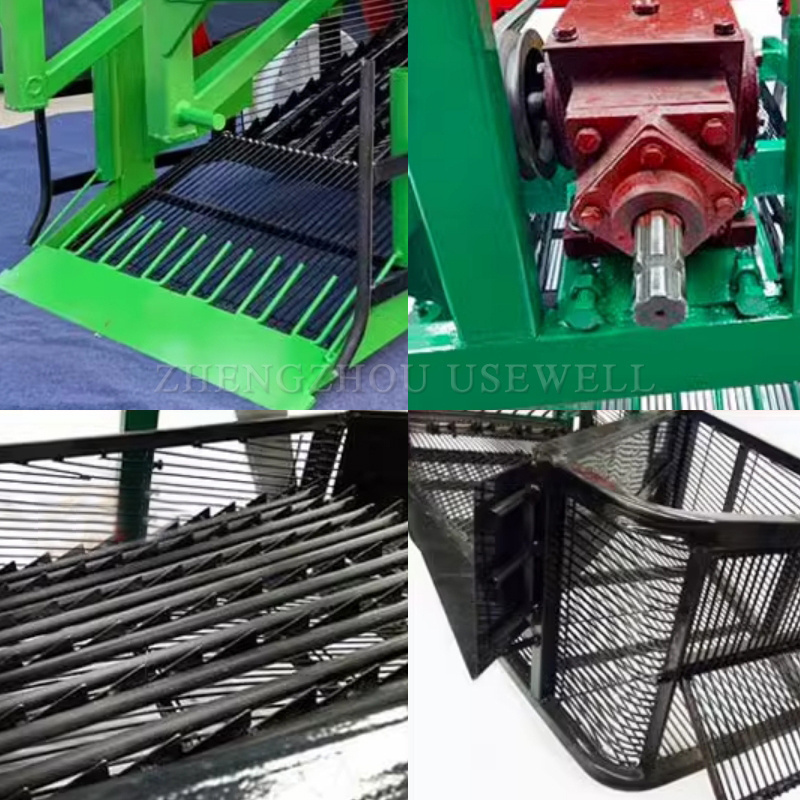

Effectively shovel peanuts at a certain depth to loosen the soil.

Barb

Effectively transport peanut seedlings from front to back.

vibrating screen

The existence of peanut falling fruit is a major problem in peanut harvesting, and the installation of a vibrating screen effectively solves this problem. By using a vibrating screen to collect and store fallen fruits, the land after receiving can be kept extremely clean, without the need for secondary manual picking up of fallen fruits.

Maintenance of Peanut Machinery:

Good maintenance will make peanut machinery serve you for a longer period of time. If it is not maintained or even cherished, no matter how good the quality is, it will wear off and the service life will be greatly reduced. The following is the daily maintenance of peanut machinery:

1. Maintenance after shift operation. After each shift of the peanut harvester is completed, the soil on the harvester parts should be removed to prevent the machine from rusting, and then the hood should be opened to remove the weeds entangled on each component.

2. Maintenance after one week of use. Grease should be added to universal joints, bearings, etc. and other lubrication points should be inspected and replenished. Check the wear of the peanut harvester belt. If the wear is serious, replace it in time.

3. Maintenance after each quarterly operation. After all the work is completed every quarter, not only should all the machines be cleaned, but the V-belts should also be loosened. After checking and replacing the bearings in each running part, add enough butter.

4. Maintenance during storage. Choose a ventilated and shaded place, use bricks or other objects to pad the frame, keep the digging shovel and depth limiting wheel off the ground, and cover the peanut harvester with plastic sheeting.

Application

Related Products

Feedback and Transction

Why Choose Us

FAQ and Contact

Hot Searches