- Product Details

- {{item.text}}

Quick Details

-

Use:

-

cow dung dewatering

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BOYE

-

Name:

-

Fecal dehydrator price

-

Capacity:

-

5-8m3/h

-

Keyword:

-

dewater machine

-

Voltage:

-

380V/220V or customized

-

Main power:

-

5.5kw

-

Rotate speed:

-

1450r/min

-

Solid moisture:

-

30-50%

-

Raw material:

-

Carbon Steel

-

Certification:

-

CE/ISO

Quick Details

-

Weight (KG):

-

300

-

Marketing Type:

-

Hot Product

-

Type:

-

dewater machine

-

Use:

-

cow dung dewatering

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BOYE

-

Name:

-

Fecal dehydrator price

-

Capacity:

-

5-8m3/h

-

Keyword:

-

dewater machine

-

Voltage:

-

380V/220V or customized

-

Main power:

-

5.5kw

-

Rotate speed:

-

1450r/min

-

Solid moisture:

-

30-50%

-

Raw material:

-

Carbon Steel

-

Certification:

-

CE/ISO

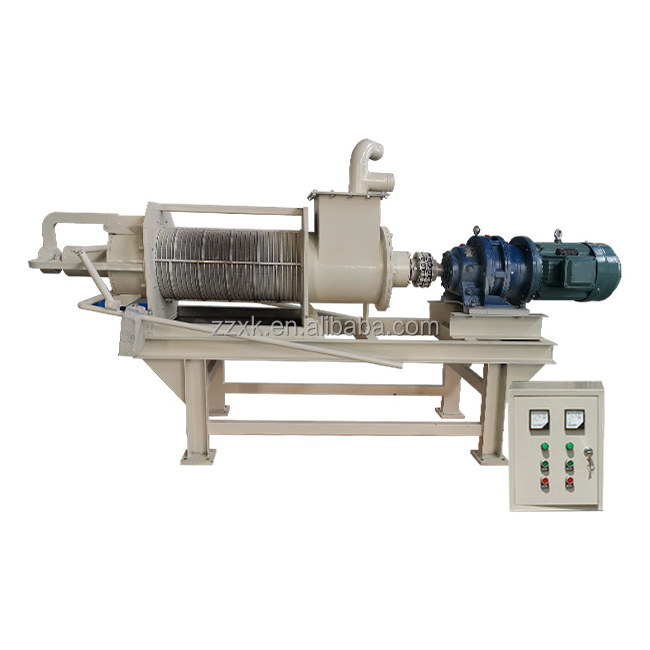

Cattle manure dewatering machine poultry cow pig chicken dung manure dewatering machine feces dewatering machine

Introduction of manure dewater machine

1.Screw press solid liquid separator is mainly consist of motor,reducer,screen,screw,pipe,pump, control cabinet.It is widely use in farm,especially for manure dewatering for cow,pig,horse,chicken,etc.

2.Manure pump conveyor manure to dewatering machine,manure being pressed and squeezed by screw in dewatering machine forward,during the time pressure become big,and solid manure being pressed out at the end,liquid being pressed out from the screen interval.

3.The separated solid part is dry and free of odor, which is a good fertilizer for farmland. No leachate is generated during storage, and it is convenient for transportation and storage.After separation, the moisture content of the liquid part is about 60%, which is not easy to form crusting and precipitation in the storage process. The liquid nitrogen and phosphorus after separation are less, which can be diluted as rrigation water or water fertilizer, and can be effectively absorbed by farmland crops.

Working Principle of manure dewatering machine

1.The principle of solid-liquid separator is spiral extrusion solid-liquid separation technology.The main components are: body, screen, extrusion and stranding, reduction motor, unloading device and other components.

2.After the cutting feed pump pumps the mixture to the solid-liquid separator through the pipeline, the separator starts, and the mixture is gradually pushed forward to the front of the body by squeezing the stringer.

3.At the same time, the pressure of the leading edge is constantly increased, forcing the water in the material to extrude the screen and flow out of the drain pipe.The work of the extruder is continuous, the material is continuously pumped into the body, the leading edge of the pressure is increasing, when to a certain extent, the discharge port will be opened, extrusion extrusion port, to achieve the purpose of extrusion.

4.In order to grasp the speed and water content of the discharge, the control device in front of the main engine can be adjusted to achieve a satisfactory and appropriate discharge state.

Features of manure dewatering machine

1.With 304stainless steel cover,which is easy to take off and observe.

2.Screw and screen adopt high quality 304SUS,Which is preservative,can use long time.

3.Easy operate,small dimension,low noise,work stable.

4.Low moisture content after press,you can’t press out water by hand.After press the moisture content is around 60%,of course it is not water weight 60%.

5.Screw is full welding,which is more durable.

Advantage of cow dung dehydrator

1. The liquid material can be directly used for crops as organic fertilizer;

2. The solid manure can be shipped to regions that lack of fertilizer to improve the soil structure. What's more, mix in the grass bran stirring, adding strain fermentation, can be made of organic compound fertilizer granulation;

3. Can be made into granular feed, fish feed for good;

4.For flowers/special economic crop fertilization, can improve soil organic matter;

5.The sale of organic fertilizer can acquire additional economic benefits.

Technical parameters of cow dung industrial dehydrator

|

BY-180 |

BY-200 |

BY-280 |

|

|

Main motor power |

4kw |

4kw |

5.5kw |

|

Voltage |

380v /50HZ |

380v /50HZ |

380v/50hz |

|

Pump power |

3kw |

3kw |

3kw |

|

Screen dia. |

180mm |

200mm |

280mm |

|

Inlet diameter |

76mm |

76mm |

76mm |

|

Over flow port diameter |

76mm |

76mm |

76mm |

|

Capacity |

8-10 M³/H |

10-15 M³/H |

20-25 M³/H |

|

Size |

1900*600*1400mm |

2100*750*1350mm |

2400*800*1280mm |

|

Drain pipe diameter |

110mm |

110mm |

110mm |

|

Weight |

340kg |

510kg |

680kg |

|

Material |

Carbon steel +304 stainless steel |

Ductile iron + 304 stainless steel |

Ductile iron + 304 stainless steel |

|

Sieve and Screw material |

304 stainless steel |

304 stainless steel |

304 stainless steel |

Packing & Shipping

1. Packing: PP film wrapped around the machine and carefully packed in wooden case to focus on protecting damageable parts.

2. Shipping: From port of Shenzhen, Shanghai, Qingdao, Guangzhou,etc. We also accept land, air, sea transport and internationalmultimodal transport.

3. Clearance: Our long history makes us the one of the first and most knowledgeable providers of the equipment, our main customers hail from; Canada, the United States, Brazil, Argentina, Japan, Philippines, Australia, Russia, Thailand, the UAE, Poland, Spain,Germany, India, etc.,

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email ,WhatsApp,Wechat or iMessages around the clock

2. Friendly English version manual

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.

If you are interested in the machine ,conact me anytime! We will reply ASAP !!!