- Product Details

- {{item.text}}

Quick Details

-

Max.Product Size(H)(mm):

-

1300 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HEALTHCARE

-

Year:

-

2021

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6480mm*3200mm*2300mm

-

Control System:

-

motion control card

-

Power (kW):

-

10KW

-

Weight (KG):

-

2.5 KG

-

Product Type:

-

CNC Contour Foam Cutting Machine

-

Material:

-

Steel Structure

-

Cutting thickness:

-

1300mm

-

Marketing Type:

-

Hot Product 2021

-

Certification:

-

CE

Quick Details

-

Cutting Speed(m/min):

-

0.1 - 6.3 m/min

-

Max.Product Size(L)(mm):

-

3000 mm

-

Max.Product Size(W)(mm):

-

2200 mm

-

Max.Product Size(H)(mm):

-

1300 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HEALTHCARE

-

Year:

-

2021

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6480mm*3200mm*2300mm

-

Control System:

-

motion control card

-

Power (kW):

-

10KW

-

Weight (KG):

-

2.5 KG

-

Product Type:

-

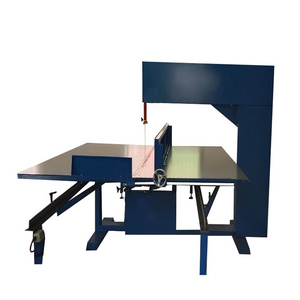

CNC Contour Foam Cutting Machine

-

Material:

-

Steel Structure

-

Cutting thickness:

-

1300mm

-

Marketing Type:

-

Hot Product 2021

-

Certification:

-

CE

Product Description

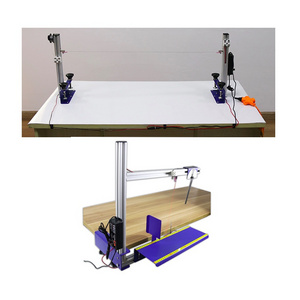

CNCHK-5 is equipped with both horizontal and vertical blade, can cut all kinds of contours for a wide range of materials, such as PU flexible foam, HR foam, Memory foam, latex and some rebounded foam. High precise cutting by means of the oscillating blade. It’s the perfect machine for foam, mattress and furniture plants.

Advantages

High precise cutting

For wider range of material

Reduce manpower

Lower use cost

Easy to operate

Dust-free

Material

PU flexible foam

HR Foam

Memory foam

Latex

Re-bonded foam

Technical Data

|

Weight(T)

|

3.0

|

Type of CNC

|

Industrial computer

|

|

Full Power

|

10KW,380V,50HZ

|

Display

|

LCD

|

|

Size(mm)

|

6480×3200×2300

|

Controlling module

|

Motion controlling card

|

|

Max foam size(mm)

|

3000×2300×1300

|

Operation system

|

Window 2000 or above

|

|

Blade size(mm)

|

2400×3×0.5

1600×3×0.5

|

Programmable axis

|

X,Y1,Y2,Z1,Z2,φ1.φ2

|

|

Servo system(r/min)

|

2400-2800

|

Step motor torque(N.m)

|

20

|

|

Max cutting Speed(m/min)

|

0-6.3

|

Min cutting radius(mm)

|

10

|

|

Admissible error(mm)

|

±0.5

|

Self-test system

|

Installed

|

|

Min cutting size(mm)

|

5

|

Blade alert

|

Installed

|

Details Images

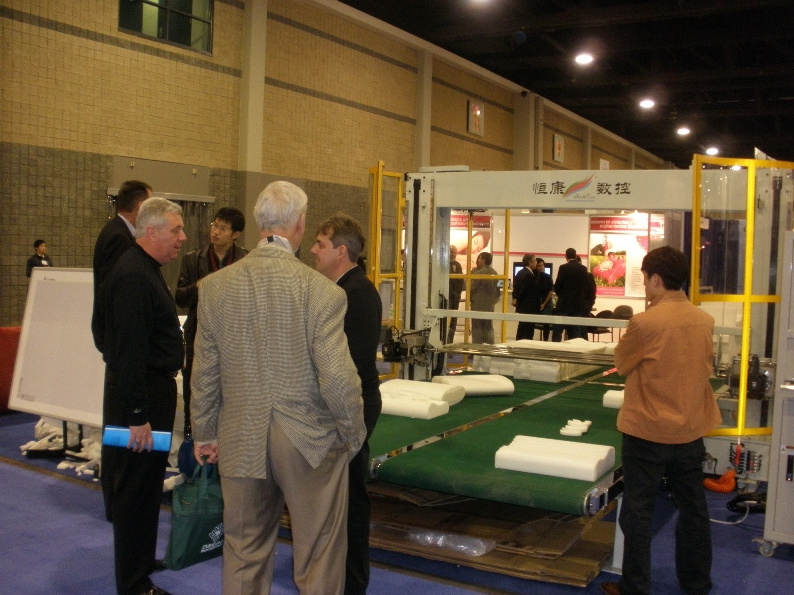

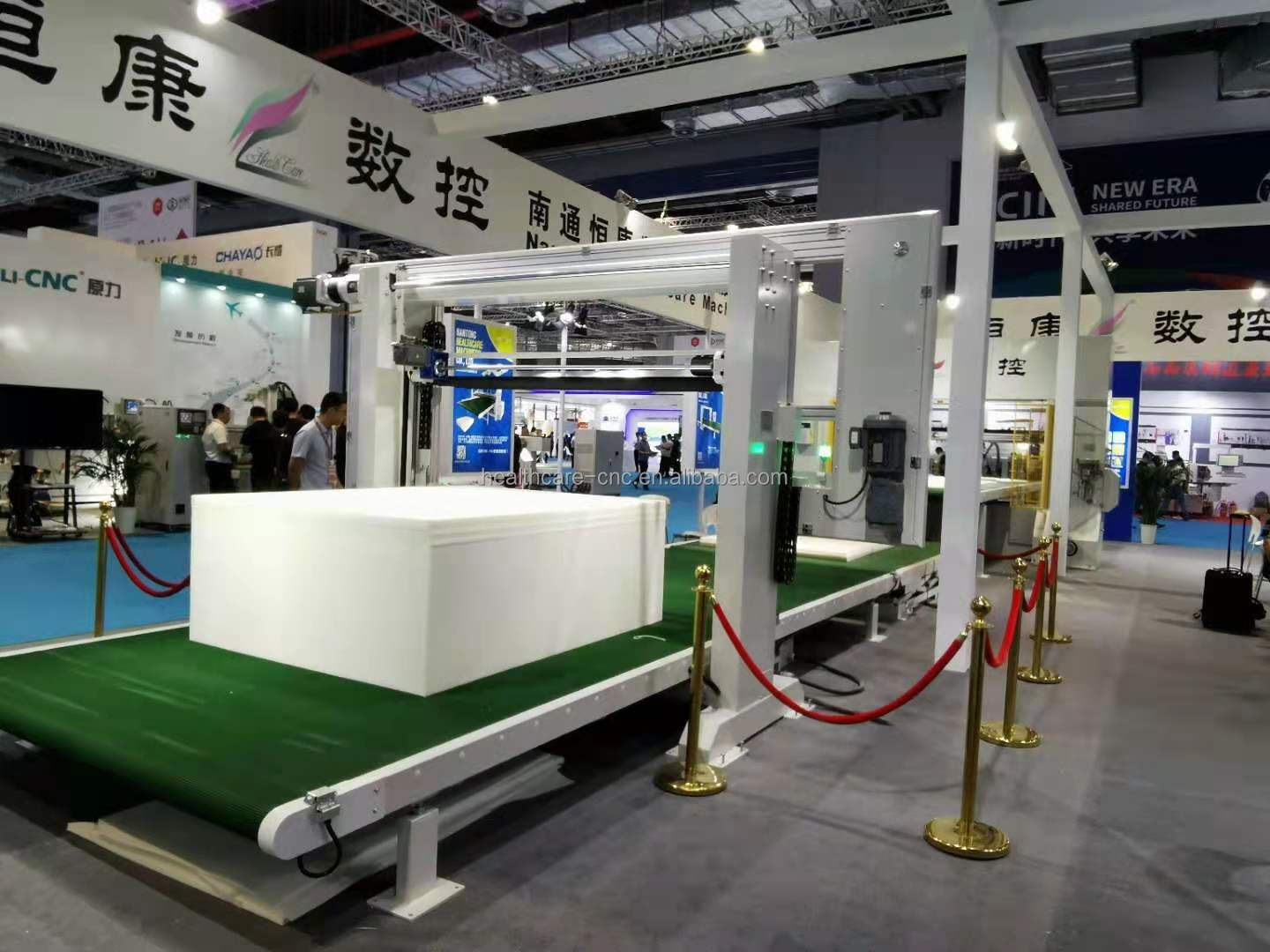

Exhibition

Company Introduction

Nantong Healthcare Machinery Co., Ltd was founded in 2007, specializing in research, design and manufacture of CNC contour cutting equipment. It is one of the first professional companies to do extensive research and development to produce Oscillating blade foam cutting machinery for the professional foam conversion. Due to the continues improvement of our existing equipment as well as new development of state of the art machinery, Nantong Healthcare Machinery Co., Ltd has won numerous national patents for their innovative ideas.

Healthcare CNC cutting machines are valued by our international customers of whom many are at the top of their industry in foam conversion. Since it was introduced in the market in 2007 the number of customers has grown rapidly and it has been the number 1 selling equipment for 10 consecutive years.

The Oscillating Blade and Continuous Blade Machines incorporate exceptional engineering design that provides for smooth, fast and efficient processing of blocks (regular foam, memory foam, latex and very hard foam) in minutes. All the machines are designed to require only one operator eliminating additional manpower. Operators all over the world appreciate the ease and usability of the Healthcare Software. Most existing files can be easily and quickly converted to DXF files making them suitable for processing foam blocks. Their System Cut Check will monitor and correct the load on the servo motors by checking for phase errors. The program will be automatically corrected adding life to the motors and increasing blade life.

Healthcare CNC cutting machines are valued by our international customers of whom many are at the top of their industry in foam conversion. Since it was introduced in the market in 2007 the number of customers has grown rapidly and it has been the number 1 selling equipment for 10 consecutive years.

The Oscillating Blade and Continuous Blade Machines incorporate exceptional engineering design that provides for smooth, fast and efficient processing of blocks (regular foam, memory foam, latex and very hard foam) in minutes. All the machines are designed to require only one operator eliminating additional manpower. Operators all over the world appreciate the ease and usability of the Healthcare Software. Most existing files can be easily and quickly converted to DXF files making them suitable for processing foam blocks. Their System Cut Check will monitor and correct the load on the servo motors by checking for phase errors. The program will be automatically corrected adding life to the motors and increasing blade life.

Our Services & Strength

1、Field installetion,commissioning and training;

2、Online support;

3、Video technical support;

4、Field maintenance and repair service.

Hot Searches