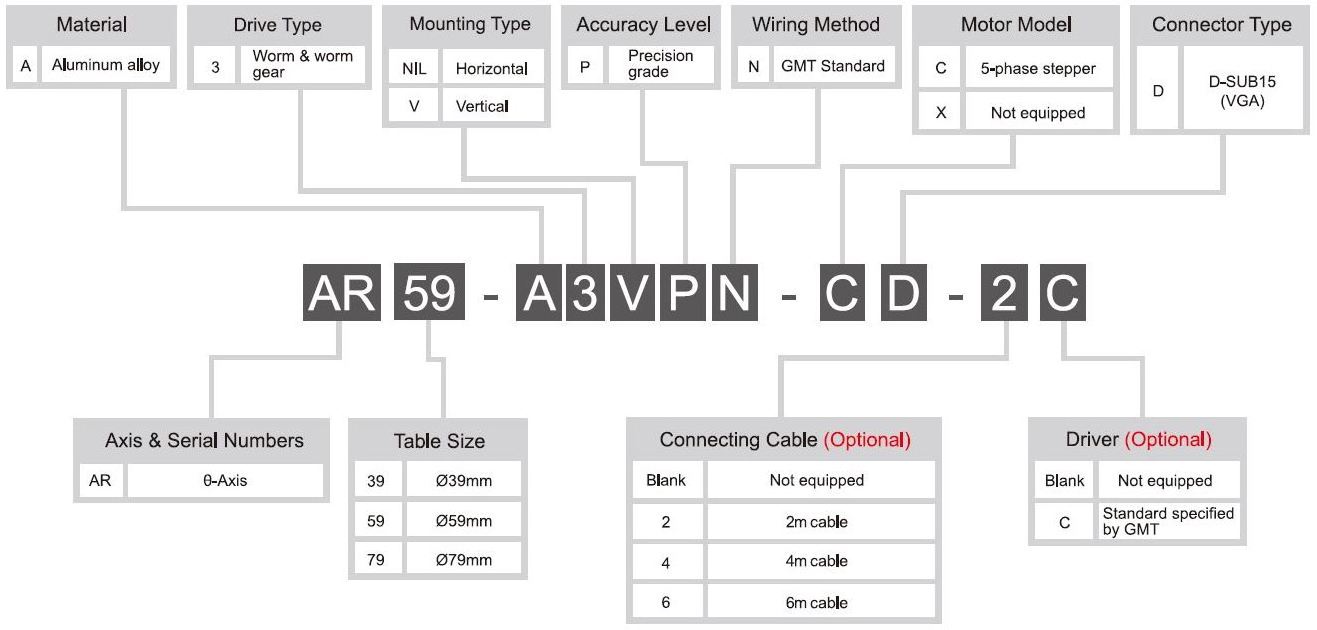

♦ For selection of the drivers preferred, please refer to the reference table or the catalogue of Motor・Driver.

♦ All of the drivers chosed are the specification of GMT preferred. For different needs, please choose the suitable drivers

according to real functional needs.

- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Taiwan, China

-

Model Number:

-

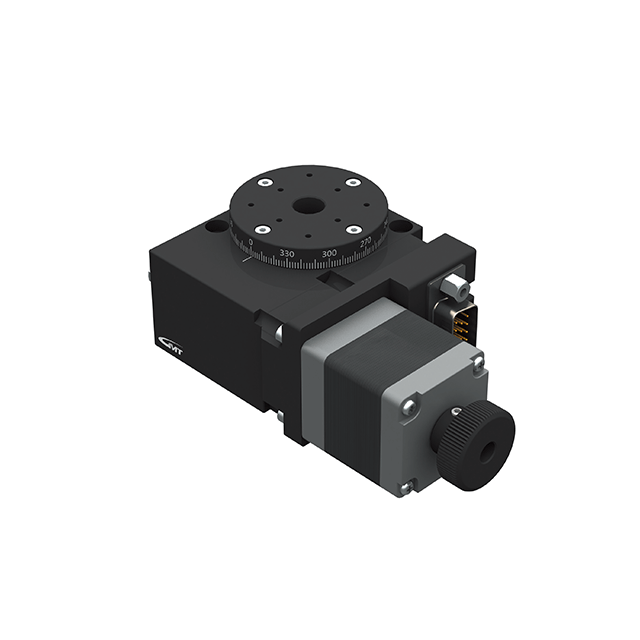

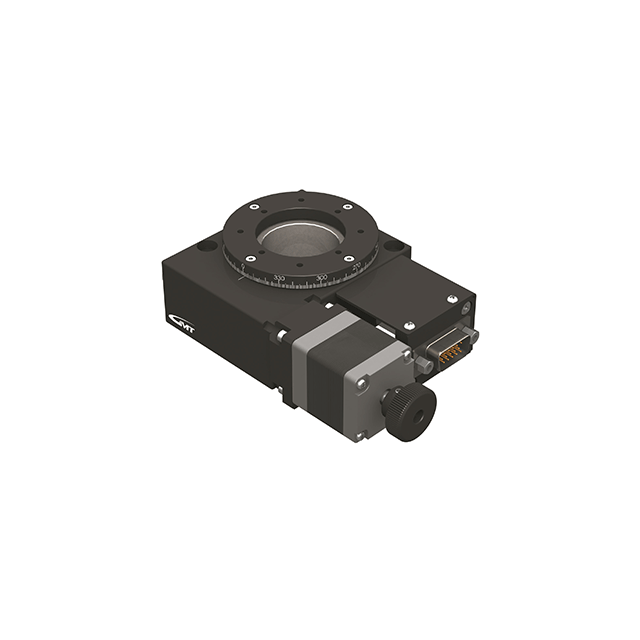

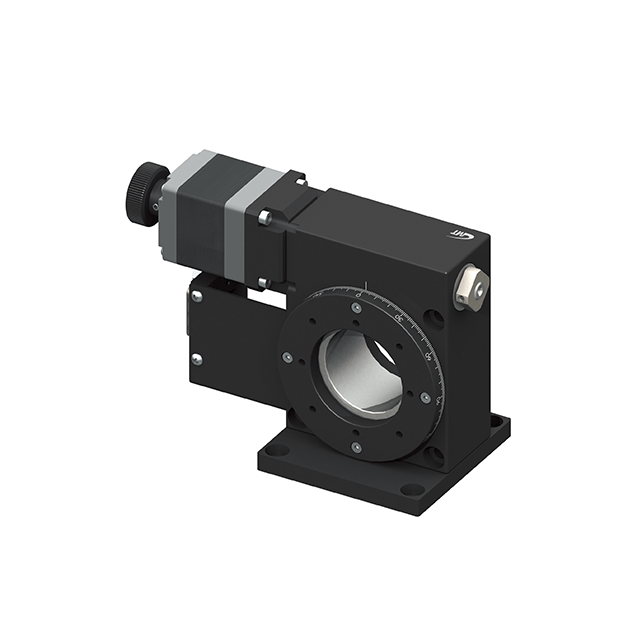

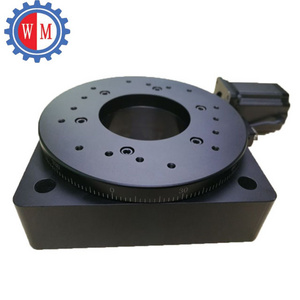

AR - Precision

Product Description

|

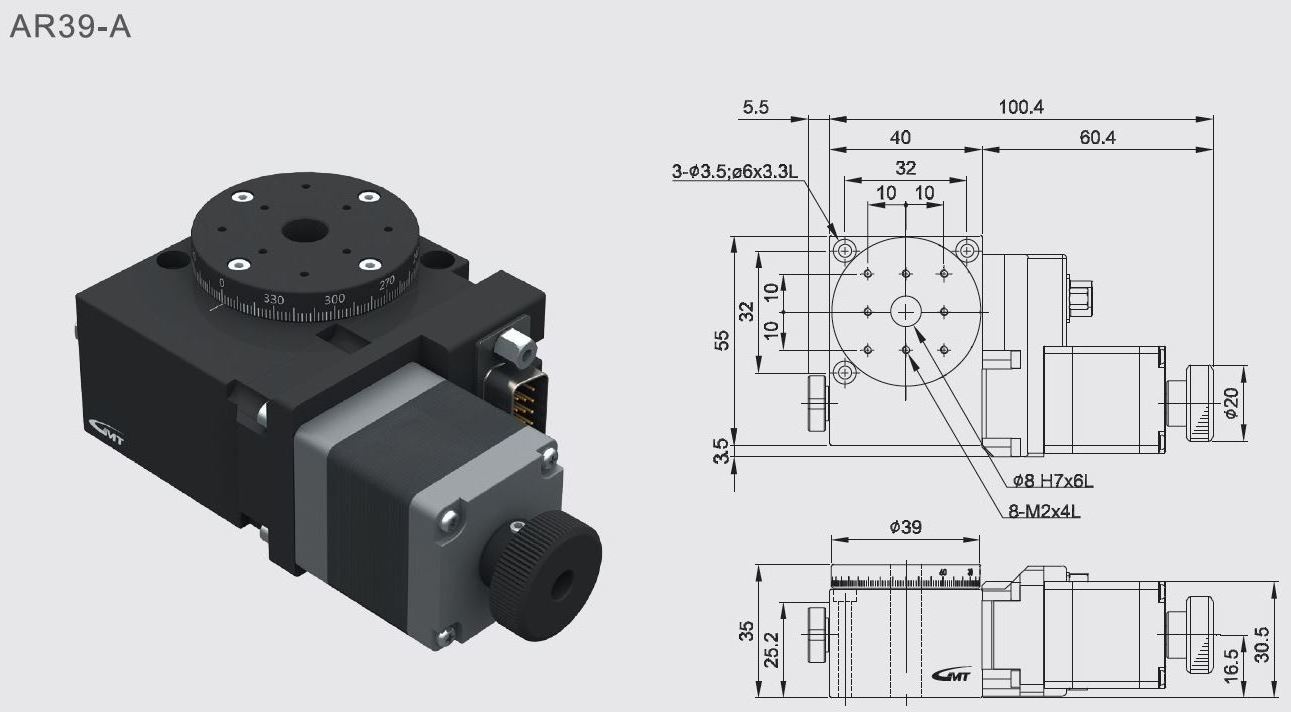

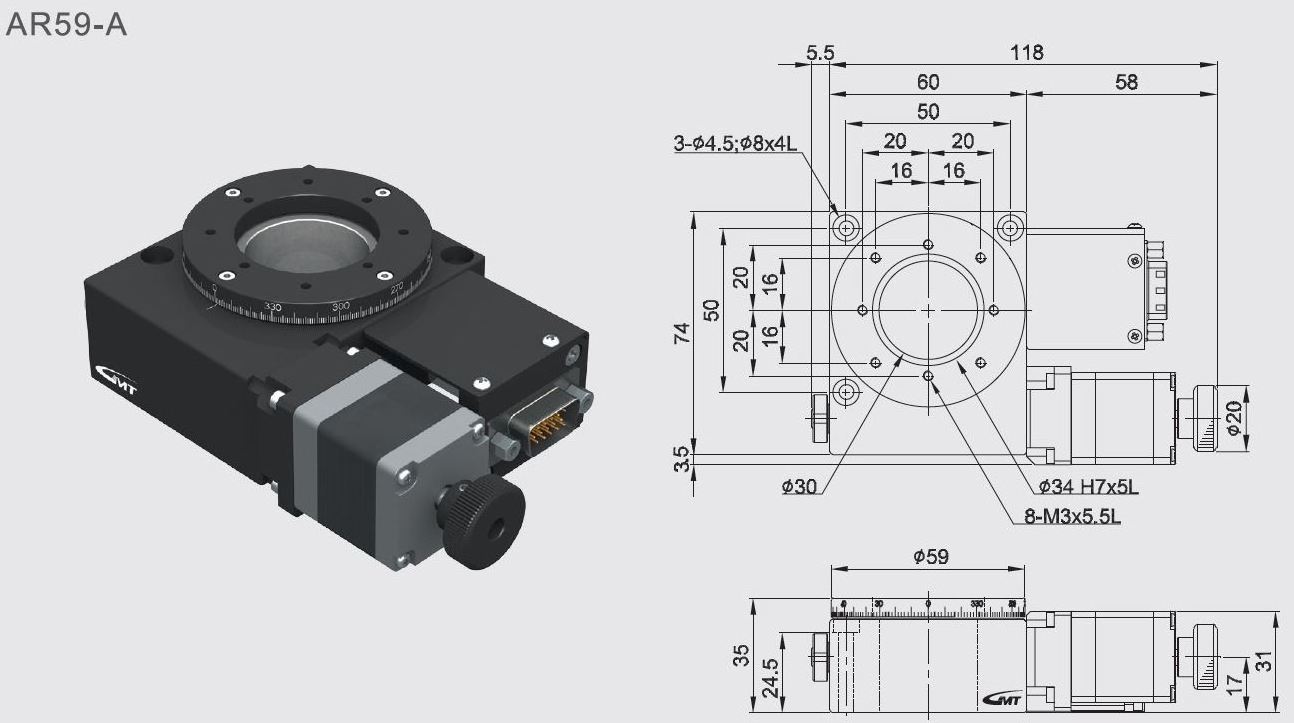

Model No.

|

AR39-A3PN-CD

|

AR59-A3PN-CD

|

AR59-A3VPN-CD

|

AR79-A3PN-CD

|

|||

|

Table Size (mm)

|

Ø39

|

Ø59

|

Ø59

|

Ø79

|

|||

|

Travel Stroke (°)

|

360

|

|

|

360

Adjustable limited rotation angle under 340°

|

|||

|

Drive Type

|

Worm & Worm Gear

(Ratio 1 / 120)

|

Worm & Worm Gear

(Ratio 1 / 180)

|

|

Worm & Worm Gear

(Ratio 1 / 144)

|

|||

|

Rail

|

Assembled Deep Groove Ball Bearing

|

|

|

Crossed Roller Bearing

|

|||

|

Stage Material

Surface Treatment

|

Aluminum Alloy

Black anodized

|

|

|

|

|||

|

Main Unit Weight (Kg)

|

0.42

|

0.62

|

0.68

|

1.05

|

|||

|

Coupling

|

FAMMS12-4*5

|

FAMMS12-5*6

|

|

|

|||

|

Accuracy Level

|

P:Precision grade

|

|

|

|

|||

|

Wiring Method

|

N:GMT Standard

|

|

|

|

|||

|

Resolution (Pulse) (°)

|

0.006 (Full)

0.003 (Half)

|

0.004 (Full)

0.002 (Half)

|

|

0.005 (Full)

0.0025 (Half)

|

|||

|

Max. Speed (Full Step) (° / sec)

|

30

|

20

|

|

25

|

|||

|

Positioning Presion (°)

|

0.05

|

|

|

0.03

|

|||

|

Repeatability Precision (°)

|

± 0.01

|

|

|

± 0.005

|

|||

|

Load Capacity (Kgf)

|

3

|

|

1

|

10

|

|||

|

Missed Step (°)

|

0.05

|

|

|

|

|||

|

Parallelism (µm)

|

30

|

|

|

40

|

|||

|

Dynamic Straightness (µm)

|

30

|

|

|

20

|

|||

|

Dynamic Parallelism (µm)

|

20

|

|

|

|

|||

|

Motor Type

Shaft Numbers

|

5-phase stepper

☐ 28 double shafts

|

|

|

5-phase stepper

☐ 42 double shafts

|

|||

|

Motor Brand

Model

|

SANYO

SH5281-7211

|

|

|

SANYO

103F5505-8211

|

|||

|

Driver Brand / Model

|

Please refer to reference table

|

|

|

|

|||

|

Stage Side Connector

|

15-Pin male end connetor D-SUB / 12-Pin male end connetor HRS

|

|

|

|

|||

|

Controller Side Connector

|

15-Pin female end connetor D-SUB / 12-Pin female end connetor HRS (Additional options)

|

|

|

|

|||

|

Origin Sensor

|

Photoelectric sensor GMT-sensor

|

|

|

Photoelectric sensor GMT-sensor

(Installed limit sensor function switch ON / OFF)

|

|||

|

Limit Sensor

|

|

|

|

|

|||

|

Origin Approximation Sensor

|

N / A

|

|

|

|

|||

|

Power Voltage

|

24V ± 10%

|

|

|

|

|||

|

Control Output

|

NPN open collector output under 24V 8mA

|

|

|

|

|||

|

Output Control

|

Testing (sensing):output transistor OFF (closed)

|

|

|

|

|||

|

Model No.

|

AR100-A3PN-CD

|

AR120-A3PN-CD

|

AR159-A3PN-CD

|

AR179-A3PN-CD

|

|||

|

Table Size (mm)

|

Ø100

|

Ø120

|

Ø159

|

Ø179

|

|||

|

Travel Stroke (°)

|

360

Adjustable limited rotation angle under 345°

|

|

360

Adjustable limited rotation angle under 340°

|

|

|||

|

Drive Type

|

Worm & Worm Gear (Ratio 1 / 180)

|

|

|

|

|||

|

Rail

|

Deep Groove Ball Bearing

|

|

Angular Ball Bearing

|

|

|||

|

Stage Material

Surface Treatment

|

Aluminum Alloy

Black anodized

|

|

|

|

|||

|

Main Unit Weight (Kg)

|

2.51

|

2.56

|

6.17

|

6.63

|

|||

|

Coupling

|

FAMMS12-5*5

|

|

FAMMS16-5*6

|

|

|||

|

Accuracy Level

|

P:Precision grade

|

|

|

|

|||

|

Wiring Method

|

N:GMT Standard

|

|

|

|

|||

|

Resolution (Pulse) (°)

|

0.004 (Full)

0.002 (Half)

|

|

|

|

|||

|

Max. Speed (Full Step) (° / sec)

|

20

|

|

|

|

|||

|

Positioning Presion (°)

|

0.03

|

|

|

|

|||

|

Repeatability Precision (°)

|

± 0.005

|

|

|

|

|||

|

Load Capacity (Kgf)

|

15

|

|

Horizontal:60

Vertical:10

|

|

|||

|

Missed Step (°)

|

0.05

|

|

|

|

|||

|

Parallelism (µm)

|

40

|

|

50

|

|

|||

|

Dynamic Straightness (µm)

|

20

|

|

|

|

|||

|

Dynamic Parallelism (µm)

|

30

|

|

40

|

|

|||

|

Motor Type

Shaft Numbers

|

5-phase stepper

☐ 42 double shafts

|

|

|

|

|||

|

Motor Brand

Model

|

SANYO

103F5510-8211

|

|

|

|

|||

|

Driver Brand / Model

|

Please refer to reference table

|

|

|

|

|||

|

Stage Side Connector

|

15-Pin male end connetor D-SUB / 12-Pin male end connetor HRS

|

|

|

|

|||

|

Controller Side Connector

|

15-Pin female end connetor D-SUB / 12-Pin female end connetor HRS (Additional options)

|

|

|

|

|||

|

Origin Sensor

|

Photoelectric sensor GMT-sensor

(Installed limit sensor function switch ON / OFF)

|

|

Photoelectric sensor GMT-sensor

|

|

|||

|

Limit Sensor

|

|

|

|

|

|||

|

Origin Approximation Sensor

|

N / A

|

|

Photoelectric sensor GMT-sensor

|

|

|||

|

Power Voltage

|

24V ± 10%

|

|

|

|

|||

|

Control Output

|

NPN open collector output under 24V 8mA

|

|

|

|

|||

|

Output Control

|

Testing (sensing):output transistor OFF (closed)

|

|

|

|

|||

System Configuration Diagram

Axis Definition

GMT has defined different axis as the following figuration according to the movement direction:

Horizontal movement direction is X and Y axis.

Vertical movement direction is Z axis.

Movement around X, Y, Z axis is defined to α axis, β axis, and θ axis.

Green arrows present the specified axis movement direction.

Horizontal movement direction is X and Y axis.

Vertical movement direction is Z axis.

Movement around X, Y, Z axis is defined to α axis, β axis, and θ axis.

Green arrows present the specified axis movement direction.

Hot Searches