- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

800

-

Key Features:

-

Auto flanging Notching Bending Machine

-

Bending Width:

-

180mm (can be customized )

-

Processing material:

-

Aluminum,stainless steel,galvanized sheet,etc

-

Bending thickness:

-

SS/galvanized sheet:0.4-1.2mm, aluminum: 0.6-1.5mm

-

Function:

-

Auto Feeding+notching+cutting+flanging+bending

-

Support Format:

-

AI PLT DXF NC

-

Feeding accuracy:

-

Length±0.1mm

-

Min. Bending radius:

-

R6mm

-

Input Voltage:

-

220V/ 50Hz /1phase or 110v/60hz/1ph

-

Flanging Width:

-

10mm

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

BST LASER

-

Year:

-

2020

-

Weight (KG):

-

800

-

Key Features:

-

Auto flanging Notching Bending Machine

-

Bending Width:

-

180mm (can be customized )

-

Processing material:

-

Aluminum,stainless steel,galvanized sheet,etc

-

Bending thickness:

-

SS/galvanized sheet:0.4-1.2mm, aluminum: 0.6-1.5mm

-

Function:

-

Auto Feeding+notching+cutting+flanging+bending

-

Support Format:

-

AI PLT DXF NC

-

Feeding accuracy:

-

Length±0.1mm

-

Min. Bending radius:

-

R6mm

-

Input Voltage:

-

220V/ 50Hz /1phase or 110v/60hz/1ph

-

Flanging Width:

-

10mm

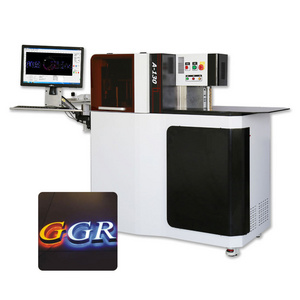

CNC 110v 220v Stainless Steel Aluminum Automatic TPS Channel Letter Flanging Notching Bending machine

Brief Introduction:

Best Laser BEL-180CUT automatic channel letter bending machine is increased notching and flanging model developed based on traditional automatic super letter bending machine. It is with high accuracy bending with the more bending bar system and quick-change bending mold system,not only with all functions of model BEL-S150 but also

it can make notching and flanging automatically for flat aluminum coil.

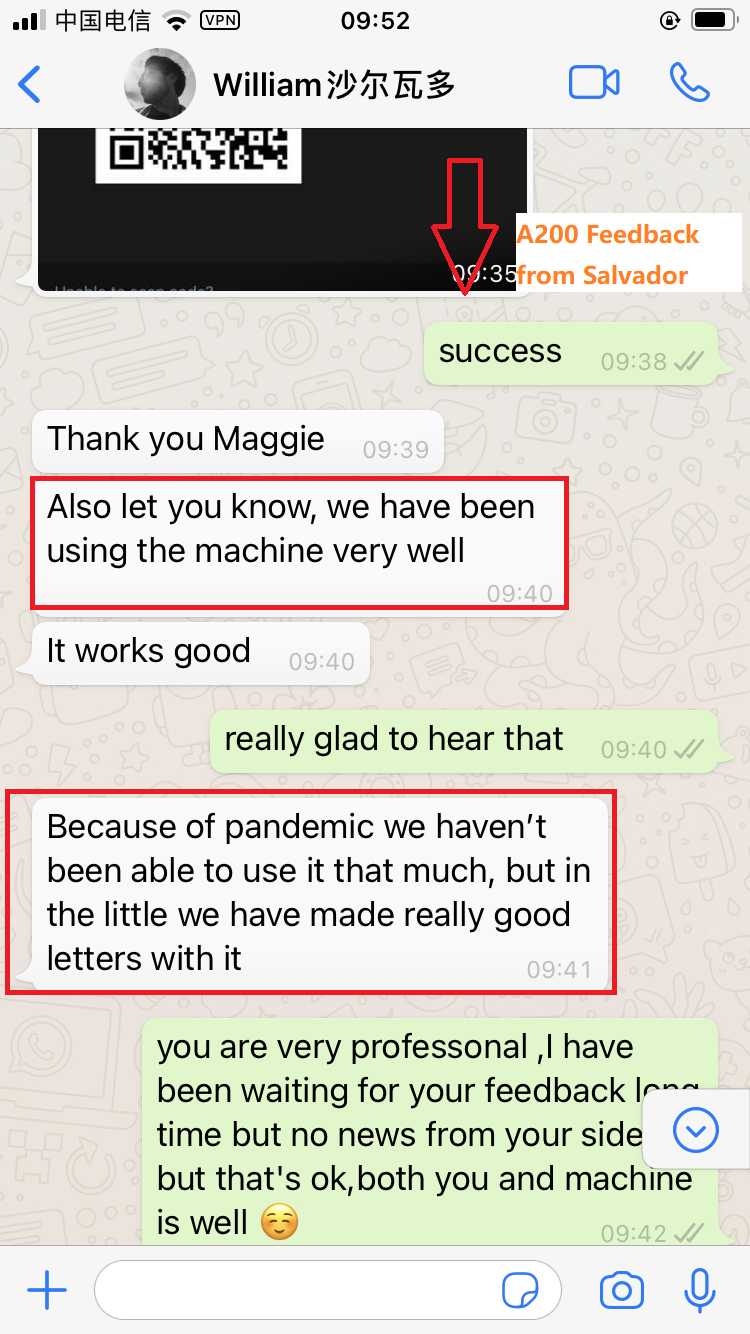

Personal User Experience from BST LASER Clients

effectively.

weak, no interference.

|

Hardware |

Feeding system

|

Precision screw transmission and mechanical arm alternatively feeding structure (closed loop self-test system)

|

|

|

Slotting system

|

Hard alloy planer

|

|

|

Notching structure

|

Notching by air cylinder

|

|

|

Flanging structure

|

Pneumatic flanging by air cylinder

|

|

|

Bending system

|

Double -pole alternate part-arc institution and patented alternative arc-extrusion structure

|

|

|

Driving motor

|

Servo motor 3 set ; stepper motor 1 set

|

|

|

Weight

|

800kg

|

|

|

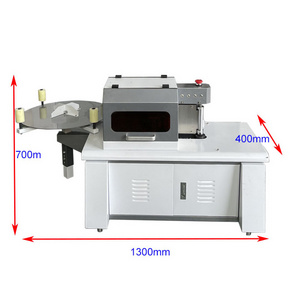

Dimensions

|

Body:L2140mm*W700mm*H1560mm;Feeding

tableL500mm*W500mm*H1100mm |

|

Performance |

Material category

|

Flat aluminum /Stainless steel / Galvanized plate (height: 20-180mm)

|

|

|

Material thickness

|

Flat aluminum :0.6 - 1.5 mm/ SS : 0.3-1.2mm / Galvanized sheet :0.4-1.2mm

|

|

|

Flanging thickness

|

Flat aluminum 0.8mm

|

|

|

Notching angle

|

30°/ 120°

|

|

|

Flanging width

|

10mm

|

|

|

Support format

|

AI / PLT / DXF / NC

|

|

|

Feeding accuracy

|

Length + 0.1mm Radius > 4mm

|

|

Software |

Control card

|

Leetro Four -axis motion control card

|

|

|

Software system

|

Auto drive / CBS4 auto bending system

|

|

|

Input voltage

|

220V 50Hz 3Kw

|

|

|

Air pressure

|

0.6-0.8Mpa

|

|

Packaging

|

|

|

|

Size

|

225*800*180cm,3.24CBM

|

|

|

Weight

|

800KG

|

|

|

Package

Details

|

Professional Export Wood Craftcase with IPCC sign

1.Outside:we adopt wood craft case

2.Middle: the machine is covered by foam, to protect the machine from

shaking.

3. Inside layer, the machine is covered by thickening plastic bag for waterproof. |

|

As 15 years laser machinery manufacturer, Best Laser is committed to providing customers with high-quality, reliable laser machines.

As a result of our quality control measures, our laser cutting machine, laser marking machine, laser engraving machine all have got CE certification. Best Laser also has got TUV certificate. High precision, low energy consumption, automatic processing, little environmental pollution and make our

products more and more industries played a important role.

To be recognized as China's foremost manufacturer and supplier of laser marking, engraving, etching and cutting systems . Dedicated to providing the best-quality equipment and services all over the world. Looking for distributors and users globally!

Pre-Sales Service :

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

Before Delivery:

* Check and test machine at least 48 hours to make sure the machine's quality.

* Also we will send you the testing report and save the machine's technical information for better after-sale service.

After-Sales Service:

* Training how to install the machine.

* Training how to use the machine.

* Engineers available to service machinery overseas.

* Lifetime technical support and service by free.

All the services above are to make sure your will have good experience using our machine.

After-sales Service Guarantee for 2 years. Maintenance free of charge for 2 years . We will provide the consumable parts at an agency price. 24 hours online service, free technical support.

Are you curious about this machine BEL-180CUT?

Here are some questions to recommend you suitable channel letter bending machine:

Full Solution for Channel Letter Making

As the machine manufacturer , we could supply full- solution on channel letter making ,

the details as below

:

1>CO2 laser cutting machine

, engraving and cutting acrylic very well, the cutting depth around 1-28mm

for different thickness.

2> CNC Router machine

, engraving an cutting MDF board and Metal.

3>Mixed Cutting Laser Cutter

, Cutting 2mm stainless steel and 20mm Acrylic /MDF

4>Fiber Metal Laser Cutting Machine,

specially for cutting thin metal materials with high precision

and speed .

5>CNC Plasma Cutting Machine

, economic metal cutting machine for cutting thin and thick metal

6> Channel letter bending machine, w

idely used for bending metal materials.

7> Advertising letter laser welding machine

is used for making a variety of stainless steel letter, LED luminous characters, LOGO, signs and other fast welding.

8>Acrylic Vacuum Forming Machine

: Making 3d advertising acrylic / plastic letter

The best way to get a good impression of the various machines is by

testing your products on our systems during a demonstration.

Interested? Let us know! Welcome your inquiry!