- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8300*1000-1560*1610

-

Power (kW):

-

42

-

Weight (KG):

-

2700 kg

-

Panel Feed Speed(m/min):

-

12m/min

-

Name:

-

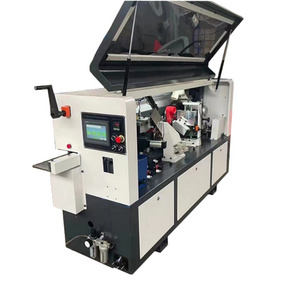

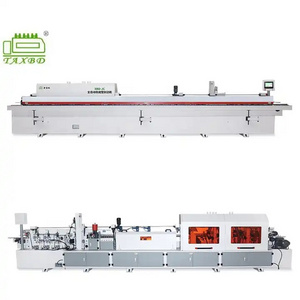

J C X L Shape Soft Forming Edge Banding Machine

-

Air pressure:

-

0.6-0.8Mpa

-

Tank volume:

-

5L

-

Glue pot operating temperature:

-

110℃-210℃

-

Edge band thickness:

-

0.52-0.56mm

-

Glue pot:

-

3000ml

-

Feeding speed:

-

12m/min

-

Type of hot melt adhesive:

-

PUR EVA

-

Edge band width:

-

J type 54mm C type 33mm

-

Application:

-

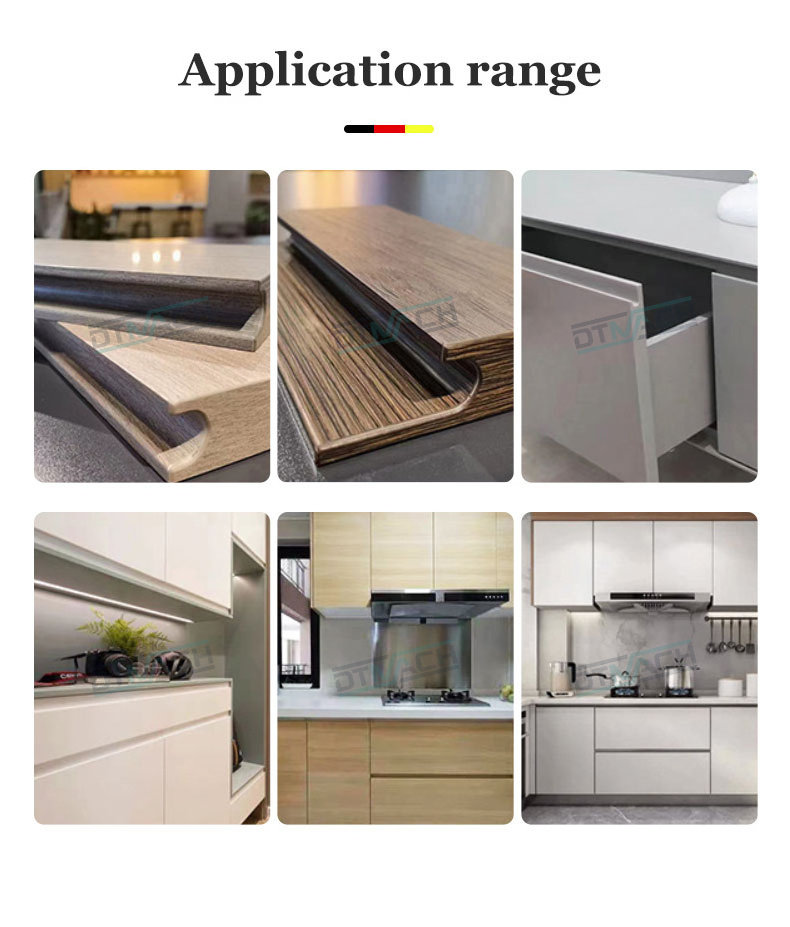

Kitchen Cabinet Wooden Furniture

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DTMACH

-

Voltage:

-

380V/50hz/3 phase can customize

-

Dimension(L*W*H):

-

8300*1000-1560*1610

-

Power (kW):

-

42

-

Weight (KG):

-

2700 kg

-

Panel Feed Speed(m/min):

-

12m/min

-

Name:

-

J C X L Shape Soft Forming Edge Banding Machine

-

Air pressure:

-

0.6-0.8Mpa

-

Tank volume:

-

5L

-

Glue pot operating temperature:

-

110℃-210℃

-

Edge band thickness:

-

0.52-0.56mm

-

Glue pot:

-

3000ml

-

Feeding speed:

-

12m/min

-

Type of hot melt adhesive:

-

PUR EVA

-

Edge band width:

-

J type 54mm C type 33mm

-

Application:

-

Kitchen Cabinet Wooden Furniture

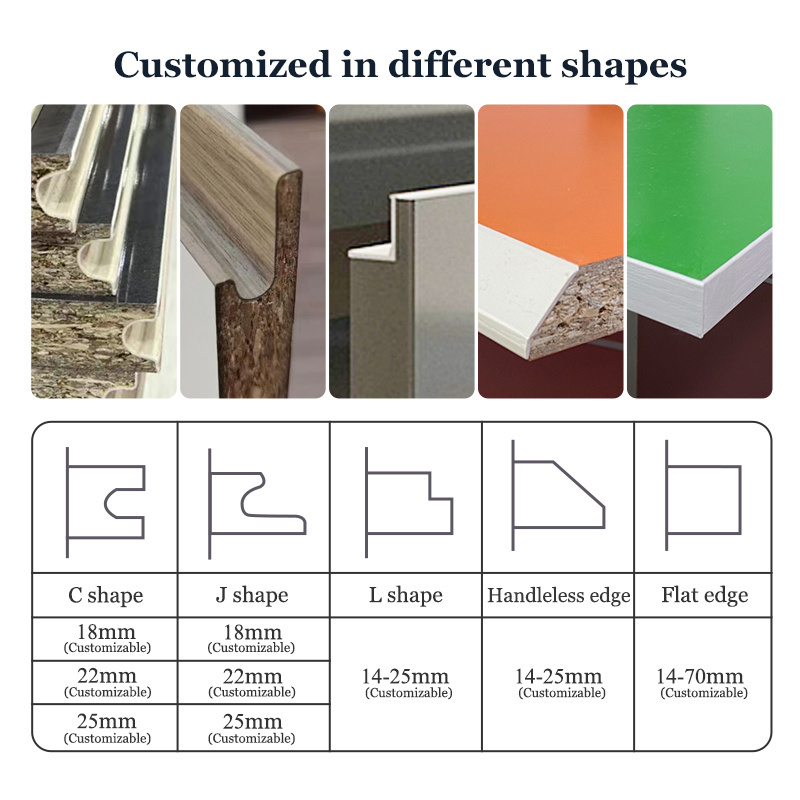

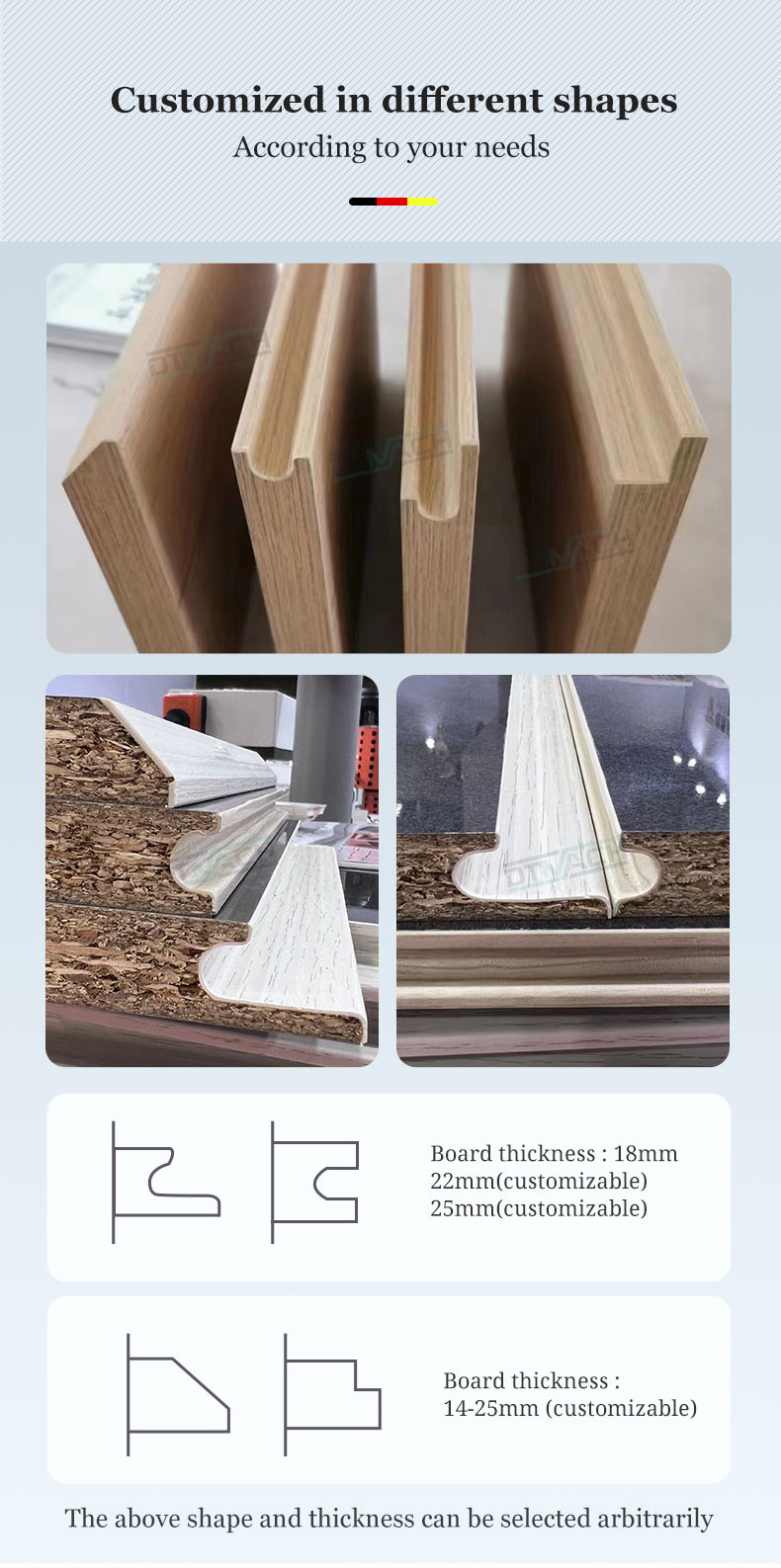

DTMACH J C X L straight shape 45 degree edge banding machine features:

1. 8 Functions:

pre-milling, gluing, bonding, end cutting, trimming, scraping, polishing and cleaning

.

2. Top glue pot: 3000ml. It can use both EVA and PUR glue to achieve the best working effect.

3. Cleaning glue pot automatically. It can discharge glue pot by one-click , which is easy to operate.

4. 3 diamond pre-milling cutter: rough milling and fine milling

5. 2 bonding system to ensure the bonding effect.

6. Cleaning device: spray anti-adhesion liquid aotumatically to make the baord clear. Recommended water-based cleaning liquid.

|

Model

|

F370

|

|

Voltage

|

380V/50hz/3 phase can customize

|

|

Total power

|

42kw

|

|

Air pressure

|

0.6-0.8Mpa

|

|

Tank volume

|

5L

|

|

Exernal dust collector

|

Φ100*8

|

|

Glue pot operating temperature

|

110℃-210℃

|

|

Edge band thickness

|

0.52-0.56mm

|

|

Glue pot

|

2600ml

|

|

Feeding speed

|

12m/min

|

|

Type of hot melt adhesive

|

PUR EVA

|

|

Edge band width

|

J type 54mm C type 33mm

|

|

Plate size

|

≥250*120mm

|

|

Plate shape

|

J shape, C shape(customized L shape, bevel straight edge)

|

|

Edge banding material

|

PVC (matter surface is recommend, no glossy surface is required)

|

|

Dimensions

|

8300*1000-1560*1610

|

|

Net weight

|

2700kg

|

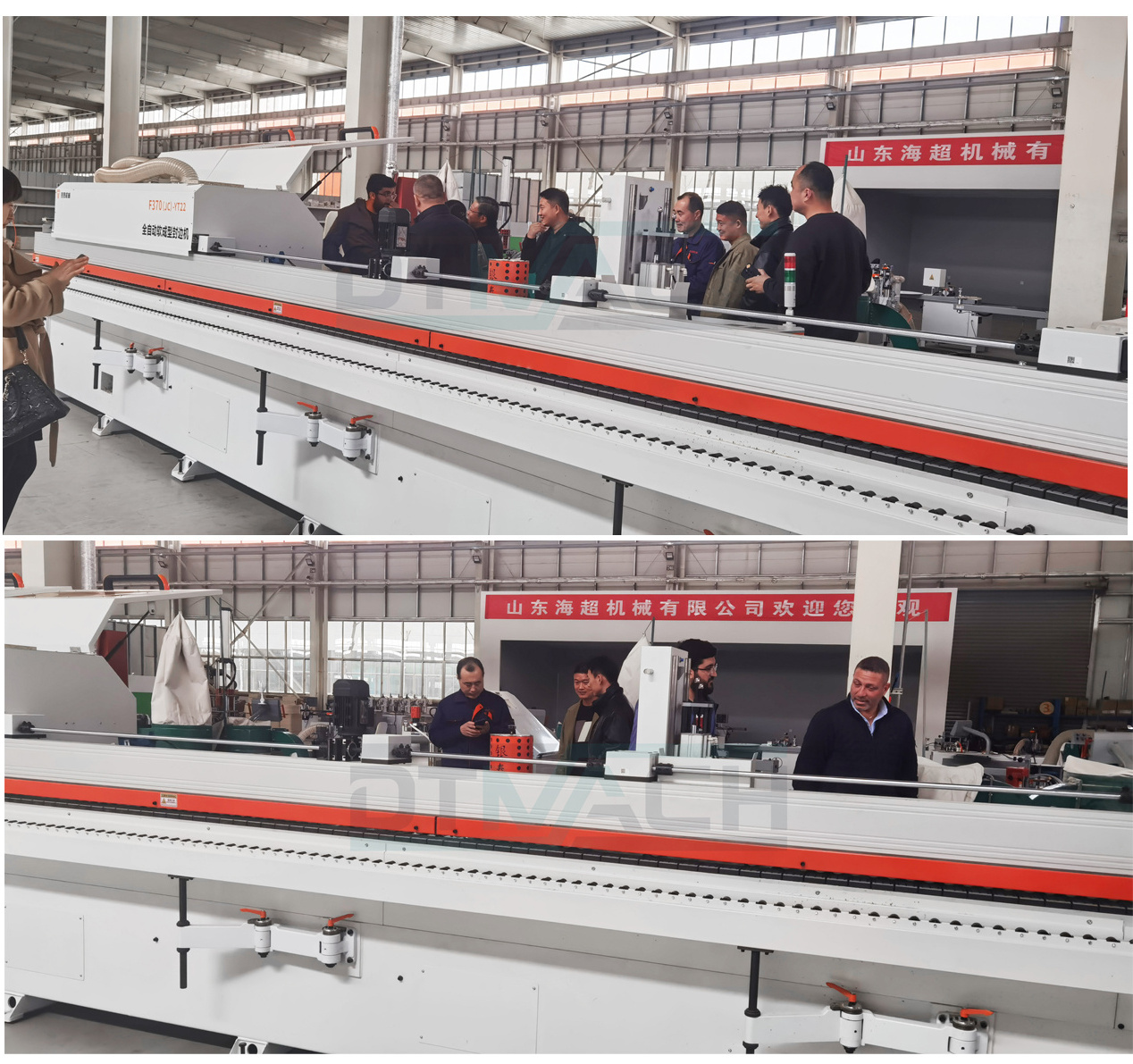

Customers come to visit the factory

Customer Feedback

Product Features

PUR/ EVA glue pot

Automatic cleaning the glue pot by one-click

2 high-power milling motors

J/C shape pre-milling of the plate, one-time forming

Fully enclosed vacuum, three vacuum ports

The position of the cylinder can be adjusted, and the J/C shape can be switched with one click.

End cutting

Cutting the excess edge band strips of two ends

Trimming both sides

Two kinds of trimming mode, cutting the excess edge band strips clearly

Scraping both sides

Make the edge of edge band strips in top and bottom of board smooth and round with a natural arc.

Polishing both sides

Make the finished effect of board better

Product Display

Application

About Us

Shandong Dongteng Machinery Co., Ltd. is committed to developing ,manufacturing and servicing of the woodworking machinery industry, improving production efficiency for the majority of manufacturers, and contributing to the development of the industry. The company’s factory covers an area of

more than 30,000㎡, with more than 200 employees, more than 20 engineers of various types, more than 100 sales, an exhibition hall area of more than 1,500㎡, and a warehouse area of more 4,000 ㎡

, providing customers with the best quality service as all times.

* In-depthcooperation with 5000companies

* 100 patents and certificates

* Factory more than 30000 square meters

* After sale Service experienced and knowledgeable team of technical support.

* In-depthcooperation with 5000companies

* 100 patents and certificates

* Factory more than 30000 square meters

* After sale Service experienced and knowledgeable team of technical support.

Certifications

Product packaging

FAQ

Q1: I want a edge banding machine , can you give me some suggestions ?

A : Sure, we will give recommend of the most suitable machine. Before that, we need to know some information, such as board thickness, strips material, local voltage etc .

Q2: Which kind of materials can be processed on this machine?

A : PVC, melamine, plastic and other materials.

Q3: Are you a factory or trading company ?

A: We are the manufacturer for 20 years. You can fully trust the machines we produce . Most importantly, we will provide you with the most thoughtful and best after - sales service.

Q4: How should I pay for my order?

A: Pay 50% as prepayment as first, then we will start to make production. When the machine is completed, we will send pictures or videos to you, and then you need to pay the balance. We will ship the machine to you after we receive your full payment .

Q5: How long is the delivery time ?

A : For standard machines, it will be 12-15 days . For customization, it will be 15-30 days .

Hot Searches