- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

121602

-

Item name:

-

vacuum form abs hard

-

Color:

-

Custom color according to pantone code

-

Size:

-

According to drawing

-

Material Available:

-

PC/ABS

-

Thickness:

-

Min 0.3mm up to 10mm

-

Process:

-

Vacuum Thermo-forming

-

Shape:

-

Customized Shapes

-

Mould material:

-

Aluminum, copper mold, timber mold

-

Feature:

-

Eco-friendly

-

Service:

-

Customized OEM

Quick Details

-

Processing Service:

-

Moulding, Cutting, Vacuum forming, Injection Molding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM Brand

-

Model Number:

-

121602

-

Item name:

-

vacuum form abs hard

-

Color:

-

Custom color according to pantone code

-

Size:

-

According to drawing

-

Material Available:

-

PC/ABS

-

Thickness:

-

Min 0.3mm up to 10mm

-

Process:

-

Vacuum Thermo-forming

-

Shape:

-

Customized Shapes

-

Mould material:

-

Aluminum, copper mold, timber mold

-

Feature:

-

Eco-friendly

-

Service:

-

Customized OEM

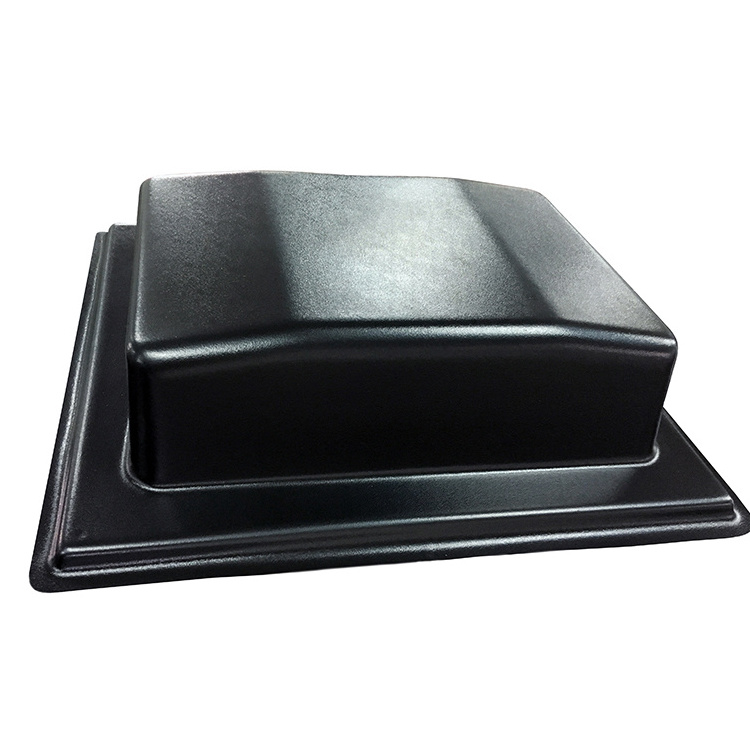

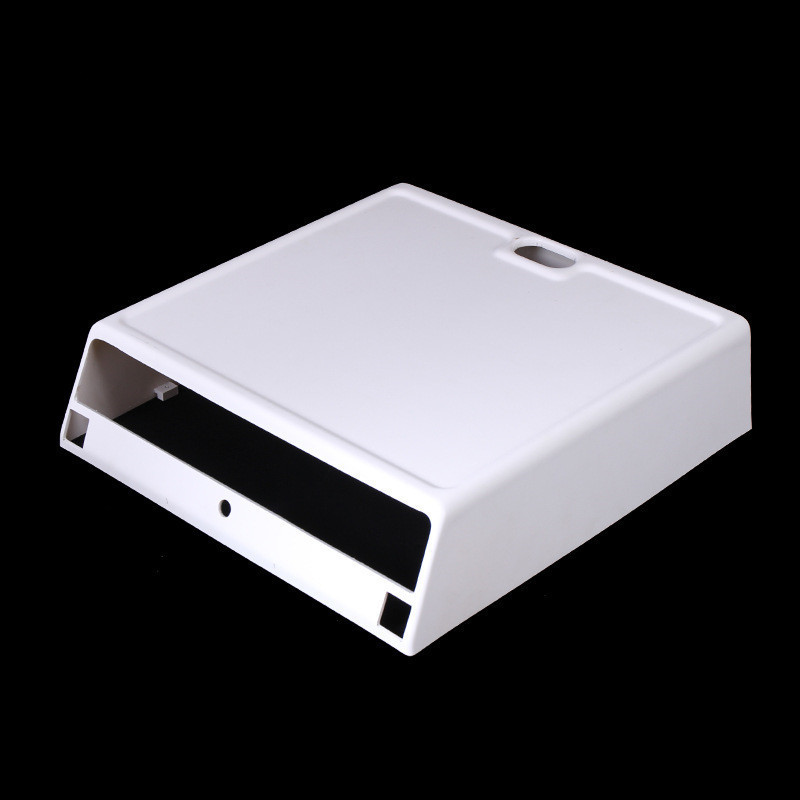

Products Description

Please kindly note all below item are custom design plastic part made by vacuum forming process. Please do not buy directly.

Thermoforming high precision Medical equipment ABS shell

|

Material Available

|

ABS,PS,PP,PVC,PET,PET-G,PMMA,PC,HDPE

|

|

Color

|

Custom color according to pantone code

|

|

Material Thickness

|

The material thickness can start from 0.3mm up to 10mm.

|

|

Surface treatment

|

The surface can have texture, spray painting, screen printing, chrome plating etc.

|

|

Mould material

|

Aluminum mold, copper mold, timber mold, plaster mold according to the product design

|

|

Design

|

custom design available

|

Details Images

Our Service

Heavy gauge vacuum forming:

Vacuum forming a simple process which you may already be familiar with, where a hot sheet is stretched over a male mold, and vacuum is applied between the sheet and the mold, pulling the sheet tight to the mold. Once it cools, the sheet takes on the shape of the tool. With our 3-dimensional trimming equipment, we can then trim out the finished part with a high degree of accuracy and repeatability. There are an infinite number of applications of this process.

1.printing on plastic sheet

printing a pre-distorted logo or graphic design onto a plastic sheet, make the mold in aluminum material or copper mold.

2.formed on mold

using vacuum forming process the plastic gets transformed into a new 3D shape and the pre-distorted image miraculously looks normal and perfectly aligned on the plastic creating vivid and engaging graphic affects.

3.finished product

After vacuum formed to the final shape, take the product off from the mold and trimmed the edges.

Pre-printed/Distortion forming:

Distortion printing is the process of printing a distorted version of an image onto a sheet of plastic and systematically vacuum forming the sheet on a mold so that specific areas of the printed image appear in corresponding areas of the resultingthree-dimensional large part.

How to work with us for the new product?

Once you have approved your design for your plastic product prototype, using either CAD/CAM or traditional pattern making, a wooden or aluminum mold is created to produce vacuum formed samples.This ensures you are satisfied with the design aesthetics, fit and function of your part before proceeding to production tooling.This is also an important stage at which to carry out any testing on the material durability and specification chosen for your product.

Related Products

Hot Searches