1. Mist spray pretreatment system

The general pretreatment as following: degrease → rinse → acid washing to dust removal → surface treatment → anodizing →water washing →deactivation → rinse →drying

Function: Removing the degrease, dust, rust on the surface of workpiece, and produce a layer Corrosion resistance, adding the adhesion of coating.

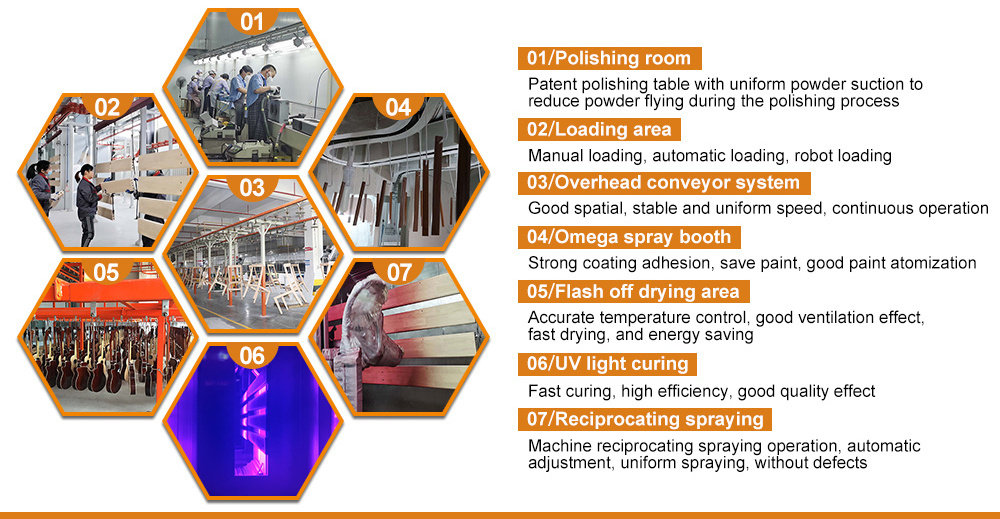

2. Powder spray system

Function: Powder spray evenly to the workpiece surface, the particular workpiece (including workpiece which easily produce electrostatic shield position) should be sprayed by a high-performance electrostatic spraying machine.

Spraying process: using the electrostatic adsorption principle, a evenly powder coating on the workpiece surface, powder collected by a recycle system, then screening and separation to be reused.

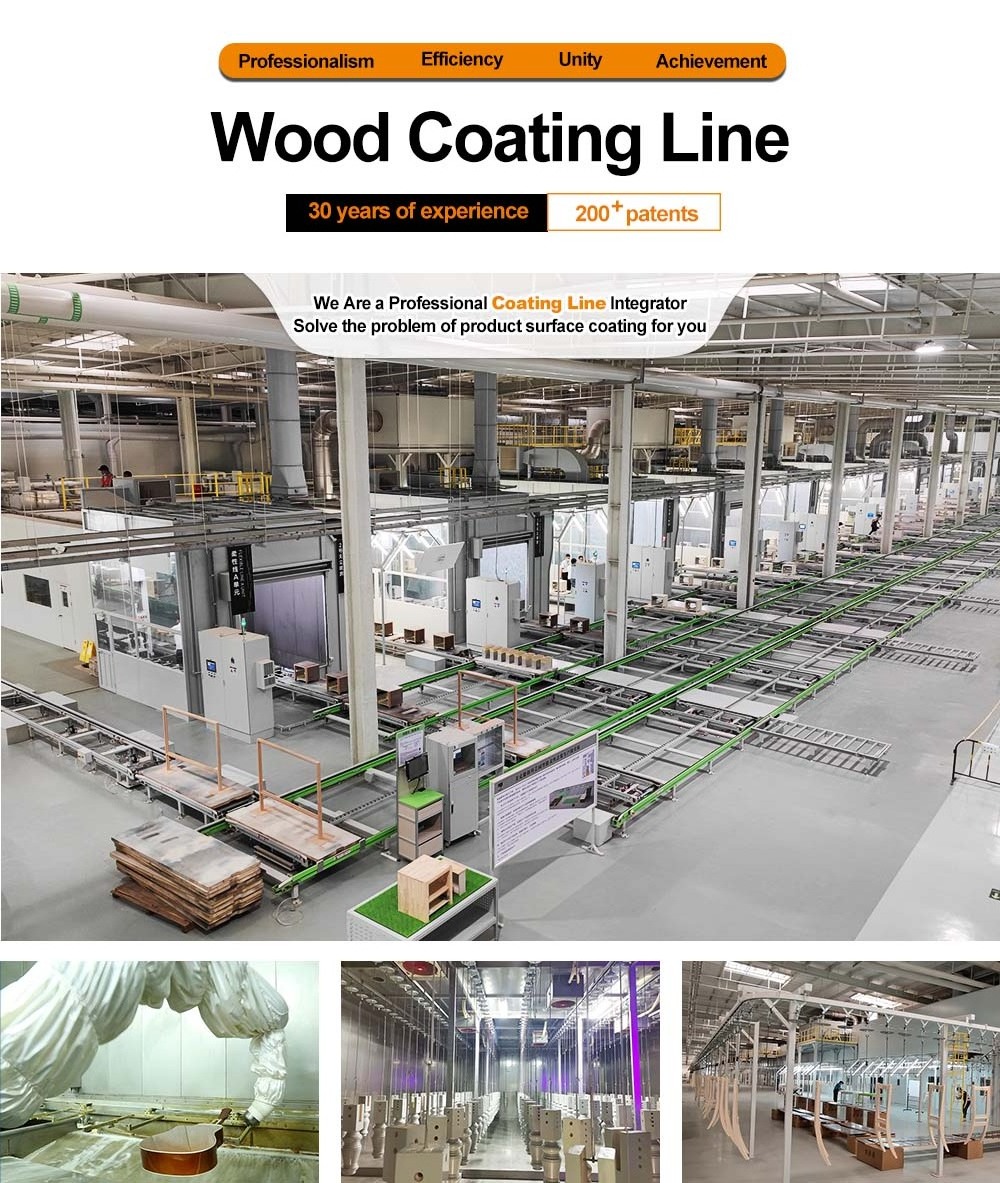

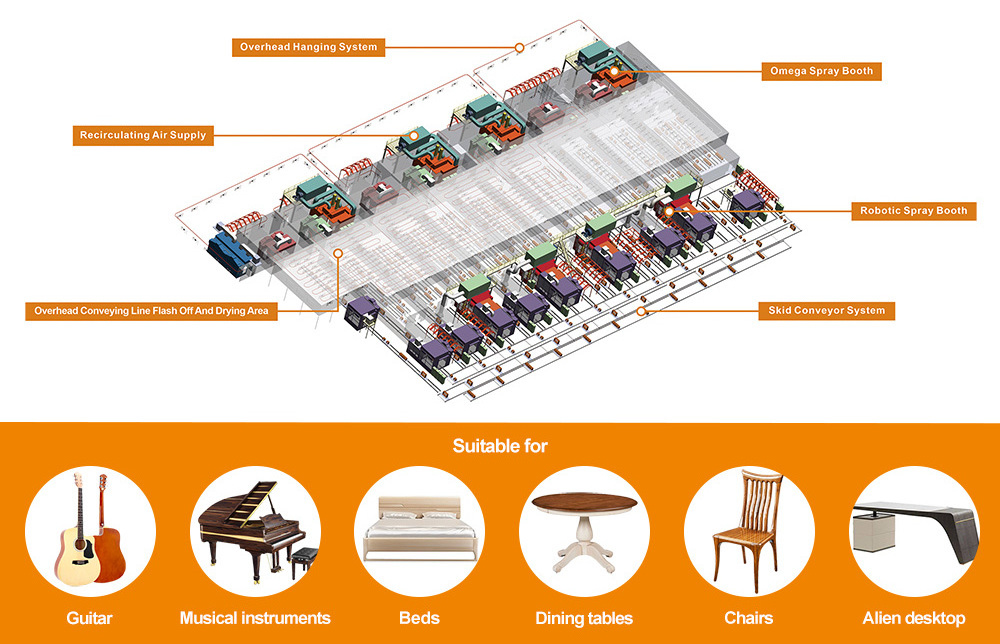

3. Spraying system

Spraying system consist of manual and robot spraying.

Function: Attractivechina paint spraying utilize oil spraying chamber, water curtain spraying chamber and robot spraying chamber.

Feature: Identified workpiece by color lens, with high efficiency identification to classify product. Insert the product information to processor (PLC, robot) to analyze and classify related process. With a high recognition rate, it is available for multiple product mixing production.

Nowadays, robot spraying has become a trend in manufacturing development. Its advantage as following:

A. Robot spraying and transferring system can reduce labor cost, realize industry automatic production.

B. Reduce safety accident, improve

C. The general robot with 6 axes, suitable with the standard related connection action with more than 6 axes, achieve high difficulty and required operation.

4. High temperature curing

Function: Heating the powder which on the surface of workpiece to a regulated temperature and timing, then perform melting, levelling and curing to achieve our required standard.

5. Heat source system

Function: We are available to supply natural gas, electricity, biologic pellet fuel etc. Based on clients" actual condition.

Quickly improve the temperature efficiency, matched with curing oven which adjustable and stable temperature, to achieve improve the product quality.

6. Electronic control system

Function: The controller installed nearby the equipment, easily to repair and maintenance, perform a central display, a stable operation.

Feature: The equipment available to connect network or utilize 4G telephone card, perform remote data collecting, intelligent monitor, realize industry 4.0. remote equipment maintenance and operation monitor, data transmit by internet, data collecting and related statement prepare by IPC.

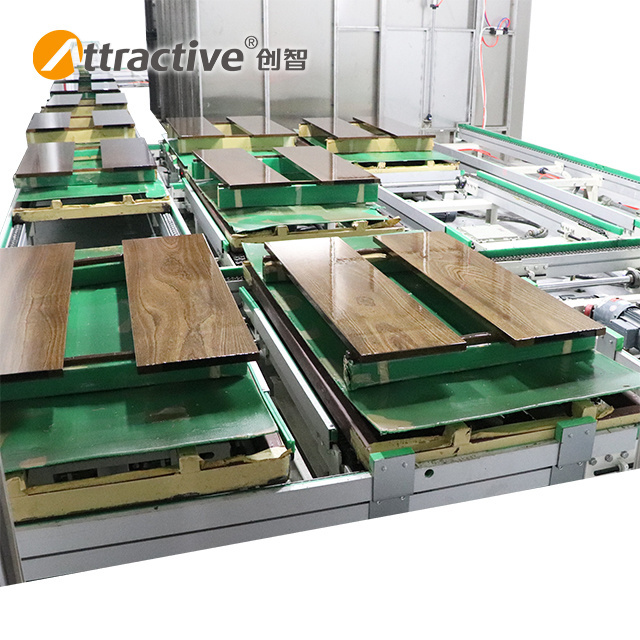

7. Conveyor system

We will design according to workpiece details and clients" required, including plate type conveyor, chain type conveyor, overhead type conveyor etc.