- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

Silicone Sealing O rings Maker

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KLB

-

Model Number:

-

KL-301G(ABC)

-

Type:

-

O ring Maker

-

English name:

-

HTV silicone adhesive

-

Chemical property:

-

Colorless Transparent gel

-

Operating temperature:

-

high temperature

-

Appliction:

-

Used for silicone rubber bonding silicone rubber

-

Storage:

-

To be kept out of the heat and sun.

-

Related categories:

-

Adhesive,glue,bonding adhesive

-

Viscosity:

-

Excellent viscosity

Quick Details

-

CAS No.:

-

Sealing maker

-

Other Names:

-

HTV silicone adhesive

-

MF:

-

food sealing Oring maker

-

EINECS No.:

-

Silicone Sealing O rings Maker

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KLB

-

Model Number:

-

KL-301G(ABC)

-

Type:

-

O ring Maker

-

English name:

-

HTV silicone adhesive

-

Chemical property:

-

Colorless Transparent gel

-

Operating temperature:

-

high temperature

-

Appliction:

-

Used for silicone rubber bonding silicone rubber

-

Storage:

-

To be kept out of the heat and sun.

-

Related categories:

-

Adhesive,glue,bonding adhesive

-

Viscosity:

-

Excellent viscosity

Silicone Seal O-ring Maker Machine Silicon Gasket Bonding Device Fast Bonding Type Adhesive

KL-301 G (A BC)

Products Description

KL-301G(ABC) ,three component adhesive swiftly cured to be silicone rubber at high temperature condition.

Elastic and tight bond performance between cured type of silicone rubbers . The adhesive is characterized with

good flowing ability before curing and elasticity electrical insulation property after cured.

Application

Applied to silicone bonding with silicone like silicone rubber ring gaskets or seals which results in waterproof ,heat resistance ,

insulation proof,moisture proof, shock absorbtion and sealing&bonding purpose.

Properties

Before curing

M ix viscosity ( 25℃ ) , m Ρ a.s: 1 000

Specific Gravity ( g/cm ³ ) : 1.10

O perable time ( 25 ℃ ), h: 7 .0

Curing time ( 17 0 ℃) ,min.: 1-2min

After curing

T ensile strength ( Mpa ) : 7 .0

Hardness( Shores A ) : 5 5±5

Elongation ( % ) : 45 0

A dhesive property : ≥2.0(A1-A1 , cohesive failure )

Volume resistance( Ω • cm ) : 1×1014

D ielectric strength ( KV/mm ) : 20

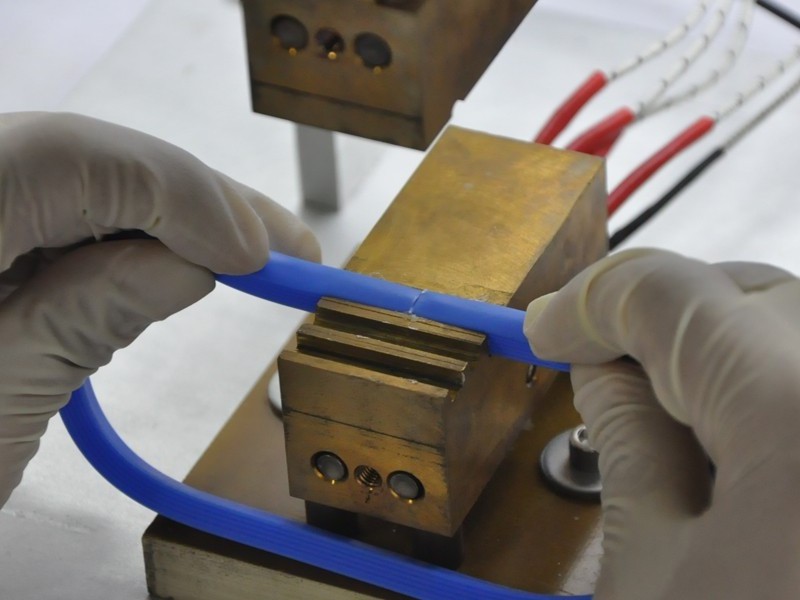

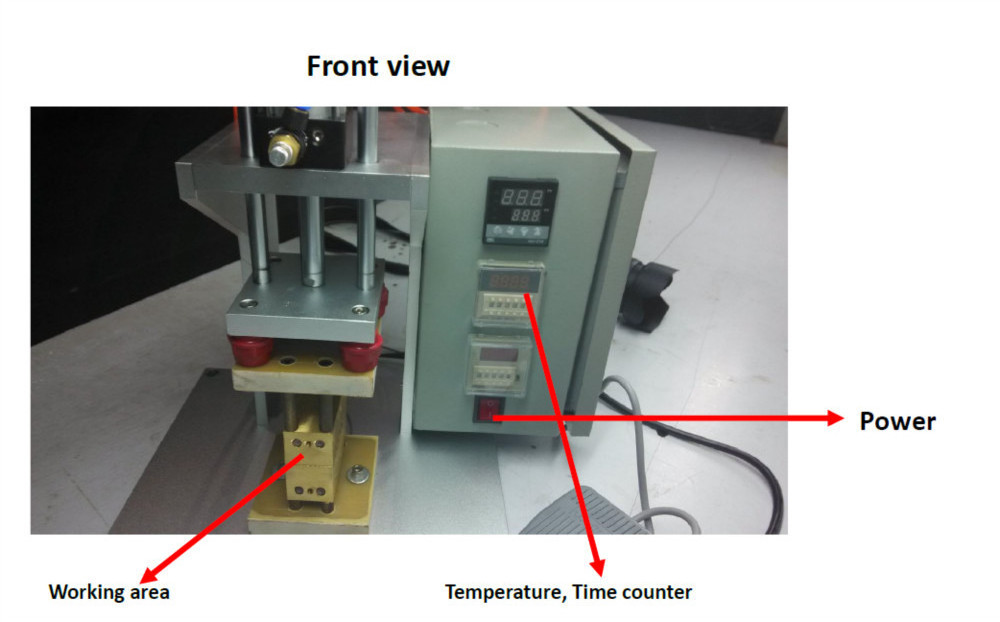

Processing

l Application ratio: A:B:C=10:10:1(weight ratio)

l The adhesive is added by weight ratio and requires thorough mixture.

l Preheat the silicone rubber bonding areas a while before applying on the mixed adhesives KL-301G.

l Heating at temperature 180°C for 15-30 Seconds.

Attention

l Keep in tight seal packings

l Curing time of KL-301G(ABC) concerns with heat transfer efficiency

and its packing sizes under the certain temperature.

l It also works for bonding cured type silicone rubber with a primer-treated metals

(CL-24S-3 primer as base Coating)

l Testing compability of rubber and base material before using. Because the compound which contained sulfur, t

in,arsenic,phosphorus,nitrogen,PB will cause bad curing during the curing process.

Packing

1kg/Bottle

Sample Provide

OEM Service(Custom Service)

Technical Support

And E fficient Production Team, Timely Deliver y

Customer Feedback:

I like the quality and the price of silicone sealant.They are top seller in my vendor list now.

—— Elizabeth Levine

I am regular buying silicone adhesive from Kanglibang,they never disappoint me. Thanks for their effort, my business goes steadily up. —— Jarek Babikowski

Our factory supplies adhesive for silicone to silicone bonding with high quality and competitive price.

Also you can follow us on youtube where you can have vivid look at how the bonding is done (copy and paste the link below)

https://www.youtube.com/watch?v=rtkDAAnskRo