- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KX-MACHINERY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2600*1200*1800MM

-

Motor Power (Kw):

-

132KW

-

Power (kW):

-

132KW

-

Weight (KG):

-

6500 KG

-

Marketing Type:

-

New Product 2024

-

Application:

-

Make Biomass Fuel Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

80-4000KG/H

-

Pellet size:

-

6/8/10/12mm Customized

-

Length of Wood Pellets:

-

Adjustable Pellet Machine

-

Product name:

-

Wood Sawdust Pellet Biomass Wood Pellet Mill

-

Color:

-

Customers' Request

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

-

Advantage:

-

Easy Operation

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1000 - 4000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KX-MACHINERY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2600*1200*1800MM

-

Motor Power (Kw):

-

132KW

-

Power (kW):

-

132KW

-

Weight (KG):

-

6500 KG

-

Marketing Type:

-

New Product 2024

-

Application:

-

Make Biomass Fuel Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

80-4000KG/H

-

Pellet size:

-

6/8/10/12mm Customized

-

Length of Wood Pellets:

-

Adjustable Pellet Machine

-

Product name:

-

Wood Sawdust Pellet Biomass Wood Pellet Mill

-

Color:

-

Customers' Request

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

-

Advantage:

-

Easy Operation

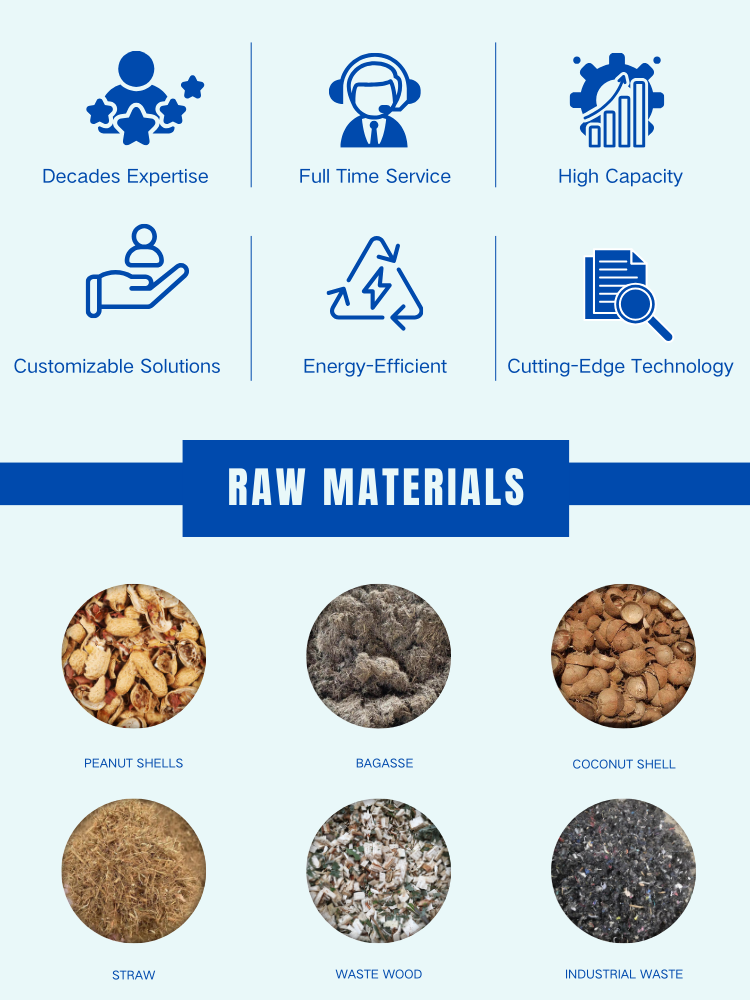

In the production of pellets, the pellet raw materials used are: corn cobs, logs, rice husks, bamboo forests, peanut shells, coconut shells, etc. These raw materials greatly increase the density of the pellets and their durability, ensuring that the pellets continue to burn.

This comprehensive use of multiple raw materials underscores our commitment to producing biomass pellets that are not only efficient but also environmentally responsible. In addition to these raw materials, we can also customize solutions according to your needs to ensure that you can choose the best biomass pellet machine for you when you choose.

Choosing the right pellet extruders

sunflower husk processing

requires careful consideration of several key factors. You can start by considering the size of your production and the specific types of wood pellets you intend to produce. For example, if you want to produce pellets with a diameter of 10MM, our models can fully meet your different production capabilities and pellet specifications.

You need look for a machine with solid construction and durable components to ensure long-term reliability. We use the latest eighth-generation pellet machine, which directly increases the output by 20%. It has a dual lubrication system and can operate continuously for 24 hours with high output.

If you have any needs, please contact us directly, we look forward to cooperating with you!

SPECIFICATIONS

|

Model

|

Main Motor

|

Capacity

|

Die Diameter

|

Weight

|

|

VRD560A

|

90KW

|

1000-2000KG/H

|

560MM

|

5.5Ton

|

|

VRD560B

|

110KW

|

1200-1500KG/H

|

560MM

|

5.5Ton

|

|

VRD580

|

132KW

|

1500-2000KG/H

|

580MM

|

6.5Ton

|

|

VRD760

|

185KW

|

2000-3000KG/H

|

700MM

|

8.5Ton

|

|

VRD850A

|

220KW

|

3000-3500KG/H

|

850MM

|

14.5Ton

|

|

VRD850B

|

250KW

|

3000-4000KG/H

|

850MM

|

14.5Ton

|

DETAILS

Superior corrosion resistance and durability ensure longevity and reliability.

Precision PLC Technology

State-of-the-art programmable logic controller for seamless operation and optimal performance.

Energy Efficiency

Environmentally friendly design reduces energy consumption without compromising productivity.

User-Friendly Interface

Intuitive controls and minimal training requirements for enhanced user experience.

Versatility in Applications

Adaptability to various industries, making it an indispensable tool for your business.

Precision PLC Technology

State-of-the-art programmable logic controller for seamless operation and optimal performance.

Energy Efficiency

Environmentally friendly design reduces energy consumption without compromising productivity.

User-Friendly Interface

Intuitive controls and minimal training requirements for enhanced user experience.

Versatility in Applications

Adaptability to various industries, making it an indispensable tool for your business.

COMPANY PROFILE

Welcome to our company, your premier destination for professional pellet machines and production line expertise. With over 20 years of industry experience, we have established ourselves as leaders in the field, delivering top-notch solutions to clients worldwide.

Our journey began over two decades ago, driven by a passion for innovation and a commitment to excellence. Since then, we have honed our expertise, perfecting our craft to offer cutting-edge pellet machines and production lines that meet the highest standards of quality and performance.

What sets us apart is our unwavering dedication to customer satisfaction. We understand the unique needs of each client and tailor our solutions to exceed their expectations. Whether you're a small-scale operation or a large-scale industrial facility, we have the knowledge and resources to support your goals.

One of our proudest achievements is our extensive international reach. Having exported our products to numerous countries across the globe, we have earned a reputation for reliability and trustworthiness in the global market. Our commitment to excellence knows no borders, and we continue to serve clients in diverse industries and geographical locations.

At our company, we believe in the power of collaboration and innovation. We work closely with our clients to understand their requirements and develop customized solutions that drive efficiency, productivity, and profitability. Our team of experts is dedicated to staying ahead of the curve, continuously exploring new technologies and techniques to ensure that our clients always receive the best possible solutions.

In addition to our unparalleled expertise, we are also committed to sustainability and environmental responsibility. We understand the importance of reducing carbon footprint and minimizing waste, and our products are designed with these principles in mind. By choosing our pellet machines and production lines, you're not just investing in quality and reliability – you're also contributing to a greener, more sustainable future.

In summary, our company is your trusted partner in pellet machine and production line solutions. With over 20 years of experience, a global presence, and a commitment to excellence and sustainability, we are your one-stop destination for all your pellet processing needs.

FACTORY DISPLAY

OUR HONORS AND QUALIFICATIONS

CUSTOMER CASES

With a proven track record of successful exports to diverse countries including Romania, Greece, India, Indonesia, Germany, New Zealand, Chile, and beyond, our company stands as a global leader in the pellet machine industry.

Our strength lies in our unwavering commitment to quality, reliability, and customer satisfaction. From the lush landscapes of New Zealand to the bustling markets of India and the dynamic energy sector of Germany, our machines have earned the trust and acclaim of customers worldwide. Our dedication to innovation ensures that our products meet the evolving needs of diverse markets, while our extensive network of partners and distributors guarantees efficient and reliable service, no matter where you are.

With us, you can be confident in finding a sustainable solution for your biomass processing needs, backed by unparalleled expertise and support.

FAQ

Hot Searches