(1)Shape memory characteristics

(2) Super elastic

(3) sensitivity to temperature changes in the oral cavity

(4) Corrosion resistance

(5) Anti-toxicity

(6) Soft correction power

(7) Good shock absorption characteristics

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

RO4200, RO4210, R04251, R04261, Nb1, Nb2

-

Shape:

-

sheet

-

Material:

-

niobium

-

Chemical Composition:

-

PURE niobium

-

Product name::

-

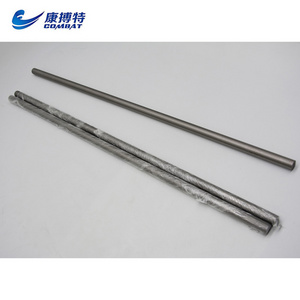

niobium tube

-

density:

-

8.57g/cm3

-

Surface treatment:

-

Polished, Vannum Annealed,Cold-rolled, Bright

-

Length:

-

(2-25)mm*(30-600)mm*Lmm

-

Purity:

-

Nb (99.95%Min)

-

Density::

-

8.57g/cm3

-

Melting point::

-

2468℃

-

key word:

-

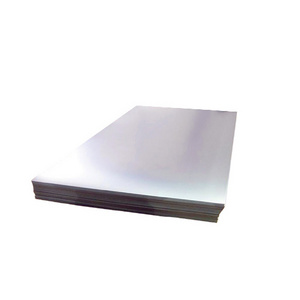

Niobium Plate

-

Color::

-

Silver Gray

-

MOQ:

-

1kgs

Quick Details

-

Application:

-

Steel,Superconductor material,Electronic,etc

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YILA

-

Model Number:

-

RO4200, RO4210, R04251, R04261, Nb1, Nb2

-

Shape:

-

sheet

-

Material:

-

niobium

-

Chemical Composition:

-

PURE niobium

-

Product name::

-

niobium tube

-

density:

-

8.57g/cm3

-

Surface treatment:

-

Polished, Vannum Annealed,Cold-rolled, Bright

-

Length:

-

(2-25)mm*(30-600)mm*Lmm

-

Purity:

-

Nb (99.95%Min)

-

Density::

-

8.57g/cm3

-

Melting point::

-

2468℃

-

key word:

-

Niobium Plate

-

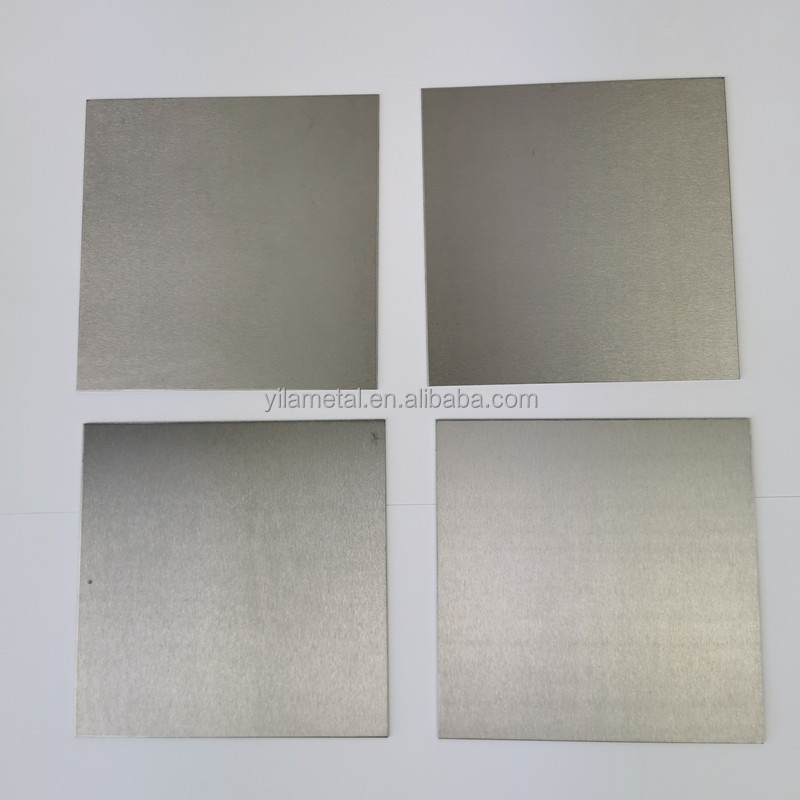

Color::

-

Silver Gray

-

MOQ:

-

1kgs

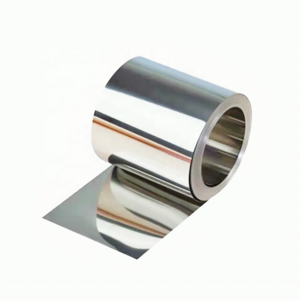

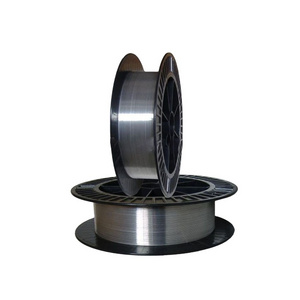

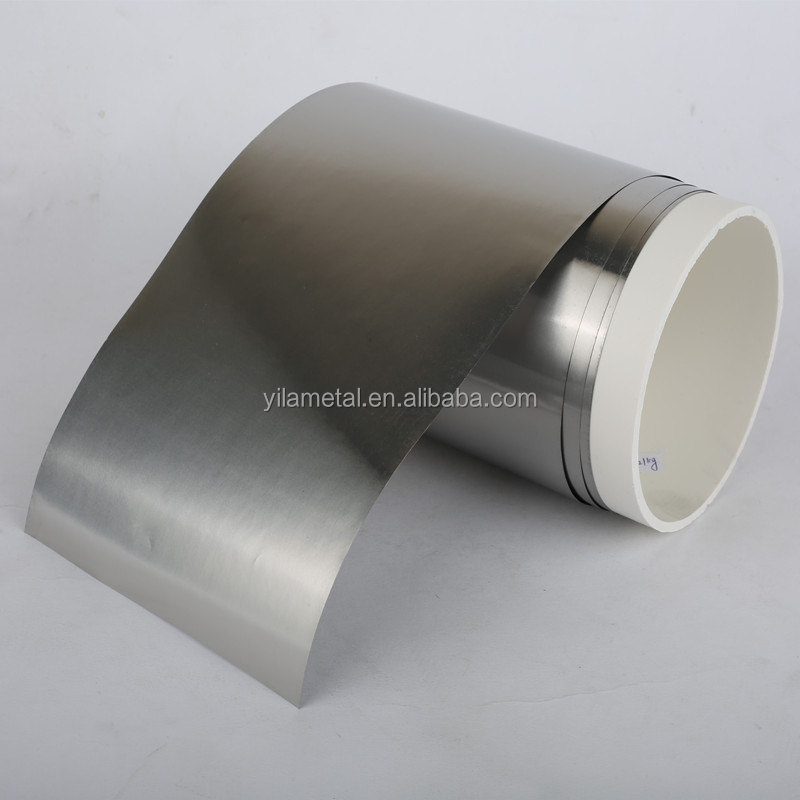

Product Show

99.95% niobium wire metal niobium filament per kg prices

Products Description

Pure

Niobium

|

Product name

|

Wholesale High Purity 99.95% Niobium

|

|

Purity

|

Nb ≥99.95%

|

|

Grade

|

R04200, R04210, Nb1Zr (R04251 R04261), Nb10Zr, Nb-50Ti etc

|

|

Shape

|

Plate/Sheet/Foil/Strip, round, block, cube, ingot etc.

|

|

Size

|

Customized size

|

|

Melting point

|

2468℃

|

|

Boiling point

|

4742℃

|

|

Advantage

|

♦ Low Density and High Specificate Strength

|

|

|

♦ Excellent Corrosion Resistance

|

|

|

♦ Good resistance to effect of heat

|

|

|

♦ Nonmagnetic and Non-toxic

|

|

|

♦ High melting point, good anti-corrosion, excellent super-conduction and other unique characteristics.

|

|

Application

|

♦ Electronic industry, Chemistry, Electronical, Pharmaceutical industry.

|

|

|

♦ Steel, Ceramics, Electronics, nuclear energy industries and superconductor technology.

|

|

|

♦ Super condouctous, metled cast ingots and alloying agents.

|

|

|

♦ Widely used in manufacturing various kinds of alloy steel, high temperature alloy, optical glass, cutting tool, superconducting

materials and other industries. |

Chemcial Composition

|

Niobium and Niobium Alloys Sheet Chemical Composition

|

|

|

|

|

||||

|

Element

|

Type1 (Reactor Grade Unalloyed Nb) R04200

|

Type2 (Commercial Grade Unalloyed Nb) R04210

|

Type3 (Reactor Grade Nb-1%Zr) R04251

|

Type4 (Commercial Grade Nb-1%Zr) R04261

|

||||

|

Max Weight % (Except Where Otherwise Specified)

|

|

|

|

|

||||

|

C

|

0.01

|

0.01

|

0.01

|

0.01

|

||||

|

N

|

0.01

|

0.01

|

0.01

|

0.01

|

||||

|

O

|

0.015

|

0.025

|

0.015

|

0.025

|

||||

|

H

|

0.0015

|

0.0015

|

0.0015

|

0.0015

|

||||

|

Zr

|

0.02

|

0.02

|

0.8-1.2

|

0.8-1.2

|

||||

|

Ta

|

0.1

|

0.3

|

0.1

|

0.5

|

||||

|

Fe

|

0.005

|

0.01

|

0.005

|

0.01

|

||||

|

Si

|

0.005

|

0.005

|

0.005

|

0.005

|

||||

|

W

|

0.03

|

0.05

|

0.03

|

0.05

|

||||

|

Ni

|

0.005

|

0.005

|

0.005

|

0.005

|

||||

|

Mo

|

0.01

|

0.02

|

0.01

|

0.05

|

||||

|

Hf

|

0.02

|

0.02

|

0.02

|

0.02

|

||||

|

Ti

|

0.02

|

0.03

|

0.02

|

0.03

|

||||

|

Grade

|

Tensile strength δbpsi (MPa), ≥

|

Yield strength δ0.2, psi (MPa),≥

|

Elongation in 1"/2" gage length, %, ≥

|

|

|

|

|

|

|

RO4200-1

|

18000 (125)

|

12000 (85)

|

25

|

|

RO4210-2

|

|

|

|

|

Thickness

|

The allowable deviation thickness

|

|

Width

|

The allowable deviation Width

|

Length

|

|

|

|

Width>120~300

|

Width>300

|

|

|

|

|

|

0.1~0.2

|

±0.015

|

±0.02

|

>300~420

|

±2.0

|

>100

|

|

|

>0.2~0.3

|

±0.02

|

±0.03

|

>200~420

|

±2.0

|

>100

|

|

|

>0.3~0.5

|

±0.03

|

±0.04

|

>200~420

|

±2.0

|

50~3000

|

|

|

>0.5~0.8

|

±0.04

|

±0.06

|

>200~420

|

±2.0(±5.0)

|

50~3000

|

|

|

>0.8~1.0

|

±0.06

|

±0.08

|

>200~420

|

±2.0(±5.0)

|

50~3000

|

|

|

>1.0~1.5

|

±0.08

|

±0.10

|

>200~420

|

±3.0(±5.0)

|

50~3000

|

|

|

>1.5~2.0

|

±0.12

|

±0.14

|

>200~420

|

±3.0(±5.0)

|

50~3000

|

|

|

>2.0~3.0

|

±0.16

|

±0.18

|

>200~420

|

±5.0

|

50~3000

|

|

|

>3.0~4.0

|

±0.18

|

±0.20

|

>200~420

|

±5.0

|

50~3000

|

|

|

>4.0~6.0

|

±0.20

|

±0.24

|

>200~420

|

±5.0

|

50~3000

|

|

Packaging & Delivery

1. In spool and plywooden box

2. In coil and woven belt

2. In coil and woven belt

Hot Searches