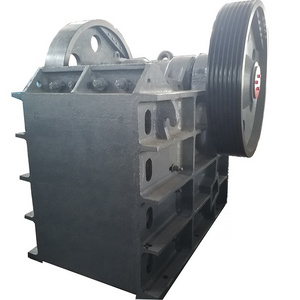

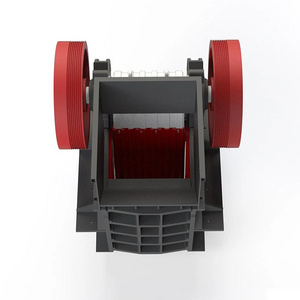

Jaw crusher is used in the first working procedure of rock crushing in all kinds of mines. All kinds of ores which compressive strength is not higher than 320MPa can be processed to medium granularity at one time. They often form a complete sand and stone production line with cone crusher, counter crusher, sand making machine, etc. It is widely used in mining, metallurgy, chemical industry, building materials, electric power, water conservancy, transportation and other fields. The jaw crusher is mainly composed of frame, eccentric Shaft, big belt pulley, flywheel, side guard, elbow back seat, gap adjusting screw, reset spring, fixed jaw plate and movable jaw plate.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

depends on different models

-

Weight:

-

1100 KG

-

Marketing Type:

-

Hot Product

-

After-sales Service Provided:

-

Video technical support

-

Feeding size:

-

125-600mm

-

Output size:

-

10-350mm

-

Certification:

-

ISO CE

-

Factory visit:

-

Welcomed Warmly

-

After-sale service:

-

12 months

-

Test&Installation:

-

Pofessional Engineer Assigned

-

Quality:

-

Superior

-

Product name:

-

Stone jaw crusher

-

Keyword:

-

Mobile Crusher Station

Quick Details

-

Application:

-

quarry crusher plant

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sino Mining

-

Dimension(L*W*H):

-

depends on different models

-

Weight:

-

1100 KG

-

Marketing Type:

-

Hot Product

-

After-sales Service Provided:

-

Video technical support

-

Feeding size:

-

125-600mm

-

Output size:

-

10-350mm

-

Certification:

-

ISO CE

-

Factory visit:

-

Welcomed Warmly

-

After-sale service:

-

12 months

-

Test&Installation:

-

Pofessional Engineer Assigned

-

Quality:

-

Superior

-

Product name:

-

Stone jaw crusher

-

Keyword:

-

Mobile Crusher Station

Products Description

Jaw Crusher

Application

Applicable Material:

River Gravel, Granite, Basalt, Quartz Stone, Iron Ore, Diabase, Limestone, Coal Gangue

Features

1. High performance. By optimizing the trajectory of the movable jaw and the cavity shape, the output is greatly improved under the same power.

2. Good stability. By optimizing the overall model and counterweight, the vibration of the fuselage is reduced, making the machine more stable during operation.

3. High product reliability. The heat treatment forging process is adopted for the eccentric shaft and main parts to make the parts stronger and more durable.

2. Good stability. By optimizing the overall model and counterweight, the vibration of the fuselage is reduced, making the machine more stable during operation.

3. High product reliability. The heat treatment forging process is adopted for the eccentric shaft and main parts to make the parts stronger and more durable.

Technical Paramenters

|

Model

|

Max.Feed Size (mm)

|

Discharging Size

(mm)

|

Capacity

(t/h)

|

Rotation Speed

(r/min)

|

Power

(kw)

|

|

PE 150*250

|

125

|

10-40

|

1-3

|

260

|

5.5

|

|

PE 250*400

|

210

|

20-60

|

5-20

|

300

|

15

|

|

PE 400*600

|

340

|

40-100

|

16-60

|

275

|

30

|

|

PE 400*900

|

340

|

40-100

|

40-110

|

275

|

55

|

|

PE 500*750

|

425

|

50-100

|

40-110

|

275

|

55

|

|

PE 600*900

|

500

|

65-160

|

50-180

|

250

|

75

|

|

PE 750*1060

|

630

|

80-140

|

110-320

|

250

|

110

|

|

PE 900*1200

|

750

|

95-165

|

220-450

|

200

|

160

|

|

PE 1000*1200

|

850

|

195-265

|

315-500

|

200

|

160

|

|

PE 1200*1500

|

1020

|

150-350

|

400-800

|

180

|

220

|

|

PE 1500*1800

|

1200

|

220-350

|

500-1000

|

180

|

280

|

|

PEX 150*750

|

120

|

18-48

|

8-25

|

320

|

15

|

|

PEX 250*750

|

210

|

15-60

|

13-35

|

330

|

30

|

|

PEX 250*1000

|

210

|

15-60

|

16-52

|

330

|

37

|

|

PEX 250*1200

|

210

|

15-60

|

20-61

|

330

|

45

|

|

PEX 300*1300

|

250

|

20-90

|

16-105

|

300

|

55

|

Hot Searches