- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FTL

-

Dimension(L*W*H):

-

3134*2736*3220mm

-

Weight:

-

50000 KG

-

Marketing Type:

-

discount

-

Keyword:

-

jaw crusher

-

Keyword 1:

-

crusher for sale

-

Product name:

-

stone crushing line

-

Raw material:

-

Iron ore,Granite,Pebble,Quartz,Limestone,Greystone

-

Usage:

-

hard stone, Mining Crushing

-

jaw crusher:

-

PE900*1200

-

Easy worn part:

-

jaw plate (high Mn Steel)

-

install foundation type:

-

concrete / steel structure

-

Features:

-

durable, High Processing Capacity

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Application:

-

road paving, construction, mining plant

-

Capacity(t/h):

-

170-400

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Dimension(L*W*H):

-

3134*2736*3220mm

-

Weight:

-

50000 KG

-

Marketing Type:

-

discount

-

Keyword:

-

jaw crusher

-

Keyword 1:

-

crusher for sale

-

Product name:

-

stone crushing line

-

Raw material:

-

Iron ore,Granite,Pebble,Quartz,Limestone,Greystone

-

Usage:

-

hard stone, Mining Crushing

-

jaw crusher:

-

PE900*1200

-

Easy worn part:

-

jaw plate (high Mn Steel)

-

install foundation type:

-

concrete / steel structure

-

Features:

-

durable, High Processing Capacity

-

After-sales Service Provided:

-

Field installation, commissioning and training

JAW CRUSHER

Stone Crusher Plant

quarry gold rock granite quartz basalt lime river stone jaw impact cone VSI crusher crushing machine production line plant price

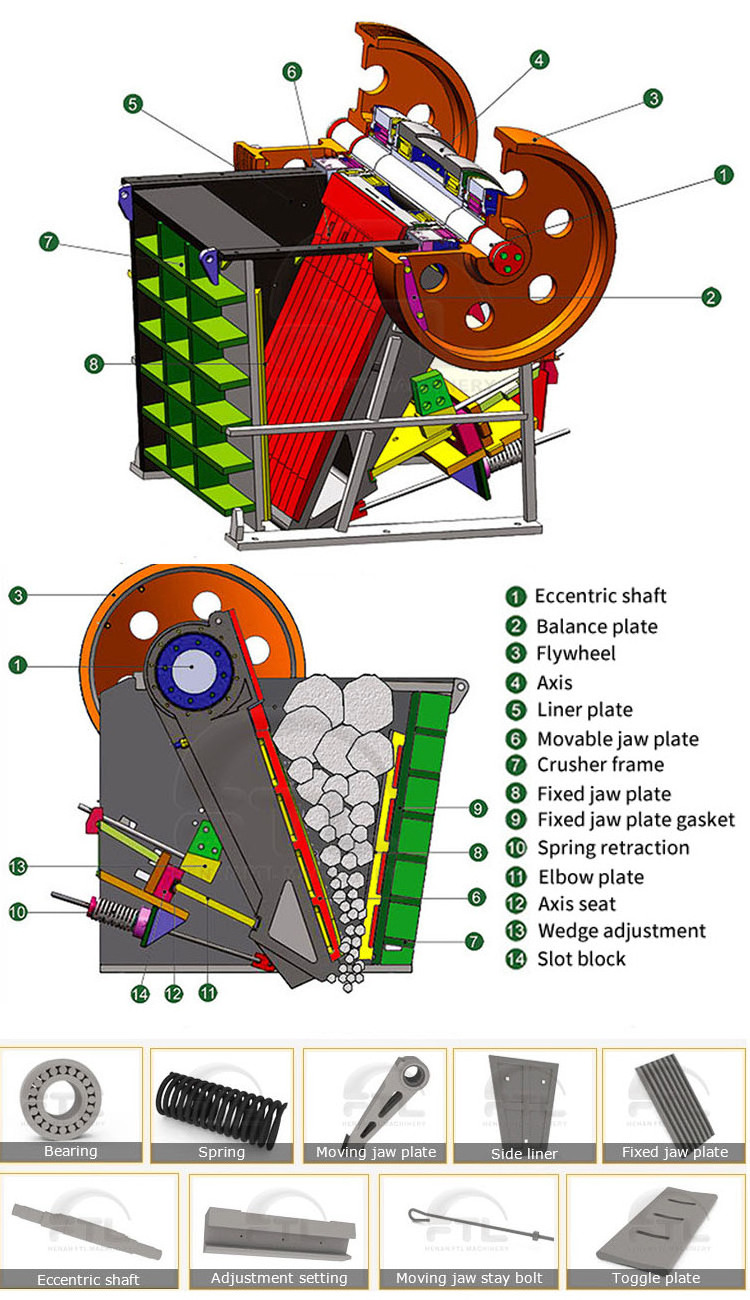

Jaw crusher are typically used as primary crushers, or the first step in the process of reducing rock. They typically crush using compression. The rock salt lump is dropped between two rigid pieces of metal, one of which then move inwards towards the rock, and the rock salt lump is crushed because it has a lower breaking point than the opposing metal piece.Jaw crusher movement is obtained by using a pivot point located at one end of the "swing jaw", and an eccentric motion located at the opposite end.

PE series jaw crusher is used for coarse crushing different kinds of ores and rocks, and PEX series jaw crusher is used for intermediate and fine crushing.

Jaw crusher machine uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the moving jaw plate move by a regulated track. Therefore, the materials in the crushing cavity ,which is composed of fixed jaw plate, moving jaw plate and side liner,can be crushed and discharged through the discharging opening.

| Model | Inlet Size(mm) | Max feeding size(mm) | Adjusting Range of Discharging outlet(mm) | Capacity(m³/h) |

Power (kW) |

|---|---|---|---|---|---|

| PE-500×750 | 500×750 | 425 | 50~100 | 25~60 | 55 |

| PE-600×900 | 600×900 | 500 | 65~180 | 30~85 | 55~75 |

| PE-750×1060 | 750×1060 | 630 | 80~180 | 72~150 | 90~110 |

| PE-800×1060 | 800×1060 | 680 | 100~200 | 85~143 | 90~110 |

| PE-900×1200 | 900×1200 | 780 | 95~255 | 100~240 | 110~132 |

| PE-1000×1200 | 1000×1200 | 850 | 195~280 | 190~275 | 110~132 |

| PE-1200×1500 | 1200×1500 | 1020 | 150~300 | 250~500 | 160 |

| PEX-150×500 | 150×500 | 120 | 10~40 | 3~15 | 11 |

| PEX-150×750 | 150×750 | 120 | 10~40 | 5~16 | 18.5 |

| PEX-250×750 | 250×750 | 210 | 15~50 | 8~35 | 30 |

| PEX-250×1000 | 250×1000 | 210 | 15~50 | 13~45 | 37 |

stone crusher plant Design Process

1. FTL stone crusher plant is mainly applied to medium or over-hard ores and stones, such as granite, iron ore, marble, etc.

2. Primary jaw crusher is equipped with enhanced jaw plates and has high reduction ratio. Main frame and flywheels use thicker steel plate; We apply impact crusher as the secondary crusher.

3. Water pipe or other washing equipments are equipped to clean the finished products.

4. Sand crusher(VSI )sand making machine or others may work as additional processing machines to diversify the final products. Tailor-made dust catcher or dust cover can also be applied to this plant.

It is applicable to the mobile crushing processes in highway, railway, metallurgy, ore mine, construction and other industries.

stone crusher plant Process

Stone ore crusher + screen production line

- 24 hours online customer service, detailed and professional solution.

- Skilled engineers, scene investigation, free customized program solution.

- The purchase contract has a certain reputation guarantee, provide you the perfect product to your hands.

- After-sales service support, Expert technical training and operating instructions, site installation and commissioning, adhere to test equipment and visit our customers regularly.

- We offer all kinds of models, high-quality crushing and screening equipment parts.

Please fill in your need products and your message and do not forget mail and/or phone . I need to ask you some details for sending you the more suitable quotation,

1.what is the raw material do you want to process?

----Such as grainite, construction waste, rock, concrete brick, gold ore, etc.

2.what is the capacity per hour do you need?

----Such as 80~100t/h, 150~200t/h.

3.what is the feature of the materials?

----Like density, moisture degeree, input particle size and output particle size.

4.what is the machine you want to buy?

---- A single machine or a production line.

If you want to learn more about us,please Chat now!