- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LD1020

-

Voltage:

-

220V

-

Power:

-

30kw

-

Dimension(L*W*H):

-

20400*3250*2500mm

-

Weight:

-

18000

-

Warranty:

-

1 Year

-

Certification:

-

ISO9001

-

Color:

-

Green

-

Speed:

-

45 cycles/min

-

Running Time:

-

24 hours

-

Function:

-

Make exercise book and notebook

-

Application area:

-

Office Sationery

-

Customer:

-

Printing press factory

-

Running Speed:

-

300 m/min

-

Notebook Size:

-

A4 A5 B4 B5 A3 and more

-

Product name:

-

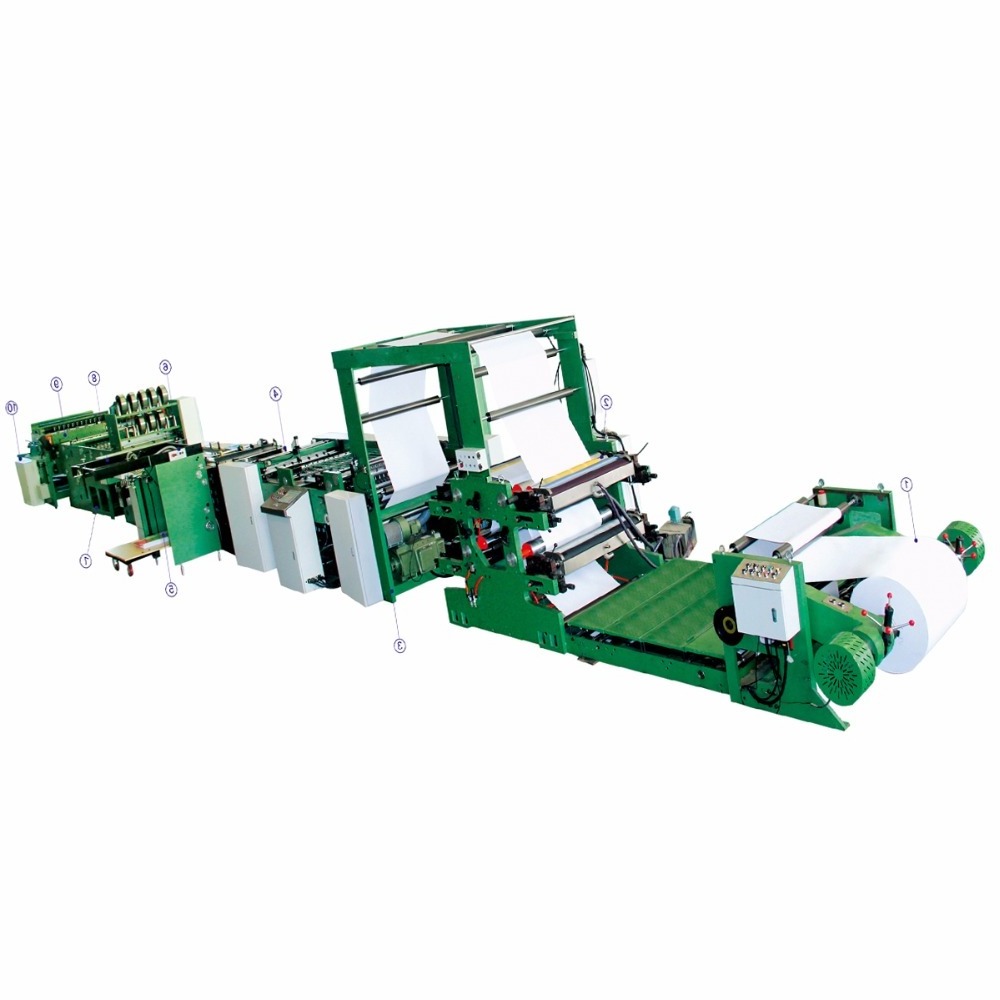

Saddle Stitching Exercise Book Making Machine Binding Machine

-

Usage:

-

Paper Exercise Book Making Machine

Quick Details

-

Type:

-

Paper Cutting Machine

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LIANDONG

-

Model Number:

-

LD1020

-

Voltage:

-

220V

-

Power:

-

30kw

-

Dimension(L*W*H):

-

20400*3250*2500mm

-

Weight:

-

18000

-

Warranty:

-

1 Year

-

Certification:

-

ISO9001

-

Color:

-

Green

-

Speed:

-

45 cycles/min

-

Running Time:

-

24 hours

-

Function:

-

Make exercise book and notebook

-

Application area:

-

Office Sationery

-

Customer:

-

Printing press factory

-

Running Speed:

-

300 m/min

-

Notebook Size:

-

A4 A5 B4 B5 A3 and more

-

Product name:

-

Saddle Stitching Exercise Book Making Machine Binding Machine

-

Usage:

-

Paper Exercise Book Making Machine

Saddle Stitching Exercise Book Making Machine Binding Machine

This machine utilizes advanced technology such as microcomputer controls, photoelectric tracking, touch screen operation and water ink flexographic printing etc. The machines are hydraulic powered and utilize gas pressure devices.

This production line is an ideal choice for mass production of staple-bound notebooks. It can make the finished wire stapled exercise book from reel paper automatically with a perfect combination of 12 Processes:

1. From One Reel Paper Unwinding,

2. High Speed Flexographic Printing With – 2 Pages & 2 Colors,

3. Rotary Slitting Knife

4. Overlapping,

5. Collation & Counting

6. Auto Cover Insertion,

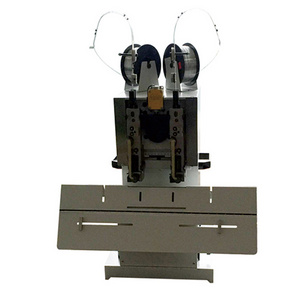

7. Saddle Stitching,

8. Folding,

9. Book Spine Pressing,

10. Cross Cutting,

11. Separate Cutting

12. Delivery to the Finished Product Collection Station.

PRINTING UNIT ADVANTAGES:

1. Rigid 60mm thick, 3000 kgs cast iron frame ensures accuracy of printing and ruling

2. It is driven by toothed timing belts to ensure printing accuracy and its working life is long.

3. Long life belts are easy and quick to fit, adjust, and maintain. It uses the hydraulic pressure control, producing full print uniform lines. Brake operation is automatic thereby saving paper.

BOOK CUTTING UNIT:

1. Using a strong 60mm thick, 4000 kgs cast iron frame ensures the stability of the cutting unit.

2. The cutter is the shear type.

3. Simple and quick to operate and adjust. The longitudinal cutters consistently cut the same size without beveling.

Writing Paper Exercise Book Notebook Making Machine

TECHNICAL PARAMETERS: