- Product Details

- {{item.text}}

Quick Details

-

Power:

-

23KW

-

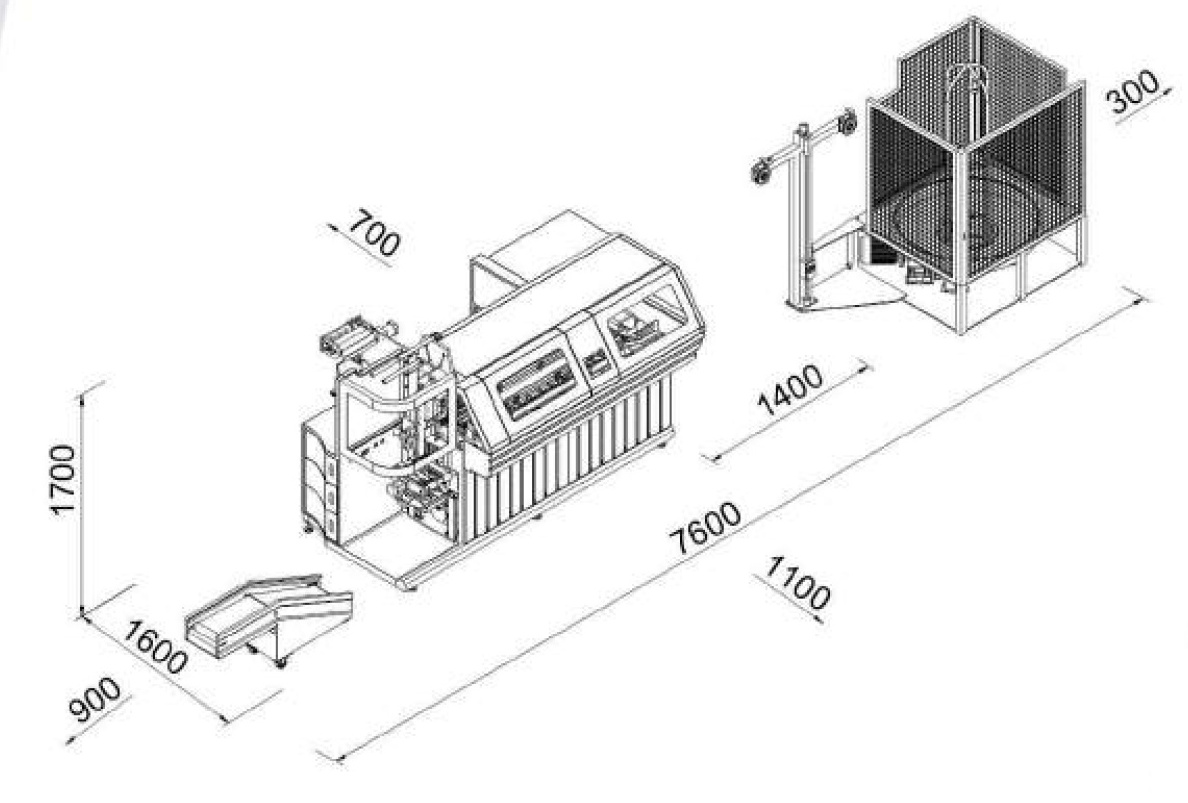

Dimension(L*W*H):

-

7600*1600*1700MM

-

Weight:

-

3200

-

Production capacity:

-

70springs/minute

-

Coiling head:

-

One servo coiling head

-

Spring shape:

-

Barrel and cylindrical,hour-glass shape

-

Working temperature:

-

+5℃ to +45℃

-

Spring wire dia range:

-

1.0-2.4mm

-

Waist Dia range:

-

28-80mm

-

Height range:

-

45-300mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

EVEREN

-

Voltage:

-

3 Phase 380V,50/60HZ

-

Power:

-

23KW

-

Dimension(L*W*H):

-

7600*1600*1700MM

-

Weight:

-

3200

-

Production capacity:

-

70springs/minute

-

Coiling head:

-

One servo coiling head

-

Spring shape:

-

Barrel and cylindrical,hour-glass shape

-

Working temperature:

-

+5℃ to +45℃

-

Spring wire dia range:

-

1.0-2.4mm

-

Waist Dia range:

-

28-80mm

-

Height range:

-

45-300mm

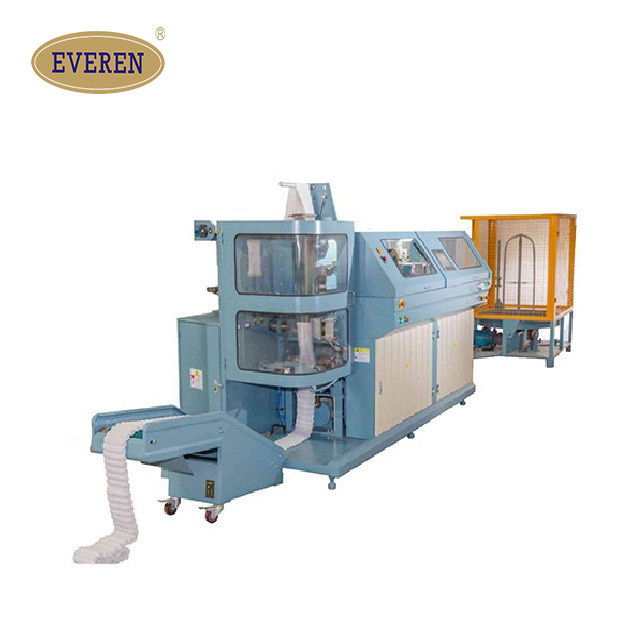

EE-PS-HX Pocket Spring Making Coiling Machine for Mattress

Feature:

-

High Efficiency

LR-PS-HX-DS (Dorsal seal) up to 70 springs/min

LR-PS-HX-BS(Bottom seal) up to 75 springs/ min -

High Stability , Low malfunction rate , Low rejection rate

-

CE-Conform ,International standard components

-

Elective bottom seal or dorsal seal

-

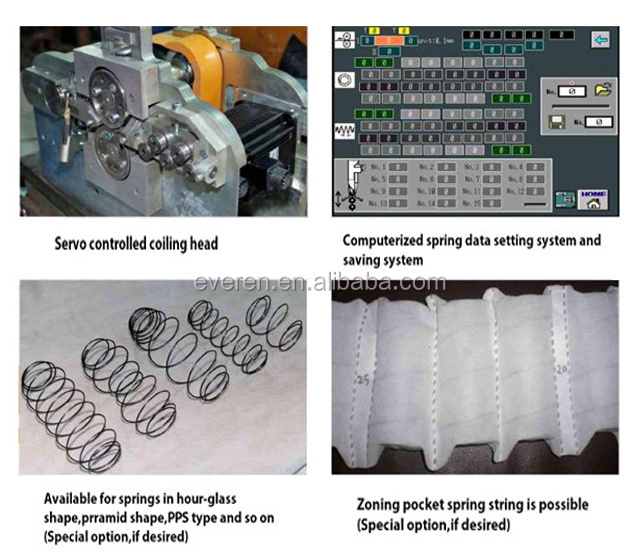

Unique patented computerized coiler (computerized numerical control system /CNC) / Coiler is full-controlled by servo and without cam / Easy and quick to change the dimension of spring by only changing the parameters in the computer

-

Saves up to 15 types of springs in different dimensions / produces different springs one by one continuously

-

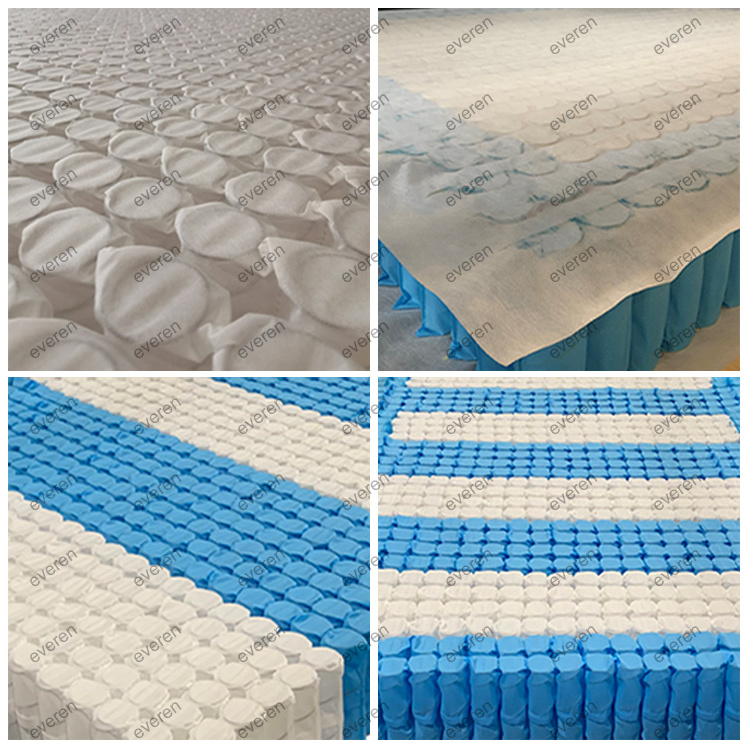

Cutter to divide the pocket springs into rows automatically (except bottom seal)

-

Intelligent sensors can check malfunctions all the time / Display corresponding alarm on the HIM duly / one operator can run several sets of LR-PS-HX alone

-

Unique patented spring conveyor design increases productivity and efficiency

-

Compact design / mechanical conveyor are controlled by servo / Accurate motions

-

Very operator user-friendly non-woven joint device / save time and non-woven

-

Ultrasonic horn is made of Titanium / Durable and Firm

-

Low and easy maintenance

-

Spare parts are“off the shelf”

- Any other Spring shape can be customized.

- Zoning pocket spring string functioncan be customized.

Technical premeter:

|

Model |

EE-PS-HX |

|

Production Capacity |

70springs/minute |

|

Coiling head |

One cam coiling head |

|

Working principle |

Servo control |

|

Spring shape |

Standard versions:Barrel and cylindrical Customized versions:hour-glass shape, pyramid shape, pps shape and so on. |

|

Air Consumption |

0. 6m³/min |

|

Air pressure |

0.6-0.7mpa |

|

Power consumption in total |

Approx 23kw |

|

Voltage |

3AC 380V |

|

Frequency |

50/60HZ |

|

Input current |

35A |

|

Cable section |

4*10mm²+1*6mm² |

|

Working temperature |

+5℃ to + 45 ℃ |

|

Weight |

Approx.3200kgs |

Consumption Material Data:

|

Non-woven fabric data |

Steel Wire |

||

|

Fabric density |

65-90g/m² |

Wire Diameter |

1.4-2.2mm |

|

Fabric width |

220-600mm |

Inner dia.of wire roll |

Min.320mm |

|

Inner dia.of fabric roll |

Min.60mm |

Outer dia.of wire roll |

Max.1000mm |

|

Outer dia.of fabric roll |

Max.600mm |

Acceptable weight of wire roll |

Max.800kg |

Working Range:

|

|

Option |

Wire Diameter (mm) |

Spring Waist Diameter(mm) |

Pocket Spring Height(mm) |

|

Standard |

Option-01 |

1.6-2.1 |

55-70 |

80-140 |

|

Option-02 |

1.6-2.1 |

55-70 |

120-180 |

|

|

Option-03 |

1.6-2.1 |

60-75 |

80-140 |

|

|

Option-04 |

1.6-2.1 |

60-75 |

120-180 |

|

|

Option-05 |

1.6-2.1 |

60-75 |

140-200 |

|

|

Special |

Option-01 |

1.0-1.4 |

28-30 |

120-150 |

|

Option-02 |

1.0-1.4 |

37-45 |

120-160 |

|

|

Option-03 |

1.0-1.5 |

30-35 |

45-70 |

|

|

Option-04 |

1.3-1.6 |

45-55 |

70-120 |

|

|

Option-05 |

1.3-1.6 |

45-55 |

120-180 |

|

|

Option-06 |

1.6-2.1 |

50-60 |

180-230 |

|

|

Option-07 |

1.6-2.1 |

60-70 |

180-230 |

|

|

Option-08 |

1.6-2.1 |

50-60 |

220-260 |

|

|

Option-09 |

1.6-2.1 |

60-70 |

220-260 |

|

|

Option-10 |

1.8-2.4 |

60-80 |

200-300 |

Q1 : What’s the warranty year of machines?

A1: One Year, except for the wearing parts.

Q 2 : What’s the delivery date?

A bout 20 to 90 days after received the deposit.

Q 3 : How to guarantee the machine quality?

A3: Our professional technicians will do repeated tests and adjustments to ensure that the quality of the machine is the best.

Q 4 : How to install and operate the machine after receiv ed the machine?

A4: We will provide pictures, videos and manual to guide you to install and operate . W e also provide the technician to door service if you need.

Q 5 : How to solve the problem during the use of machine?

A5: If any questions during the use, please send us the description of problem together with pictures or videos , our professional after-sales team will reply you immediately.