- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Machine matreial:

-

304 Stainless Steel

-

Raw material:

-

Waste Paper

-

Attribute:

-

Egg tray making machine

-

Power supply:

-

380V, 50HZ, 3Phase

-

Output:

-

700-800pcs/h

-

Finished products:

-

Egg tray/box,fruit tray,wine packs,seed pots,cup tray...

-

Main system:

-

Pulp making system, forming machine, drying line, packing part

-

Products size:

-

According to your design and samples

-

Drying method:

-

Coal,diesel oil,natural gas,electricity.etc

Quick Details

-

Production Capacity:

-

700-800pcs/h

-

Place of Origin:

-

Shandong, China

-

Certification:

-

ce

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Machine matreial:

-

304 Stainless Steel

-

Raw material:

-

Waste Paper

-

Attribute:

-

Egg tray making machine

-

Power supply:

-

380V, 50HZ, 3Phase

-

Output:

-

700-800pcs/h

-

Finished products:

-

Egg tray/box,fruit tray,wine packs,seed pots,cup tray...

-

Main system:

-

Pulp making system, forming machine, drying line, packing part

-

Products size:

-

According to your design and samples

-

Drying method:

-

Coal,diesel oil,natural gas,electricity.etc

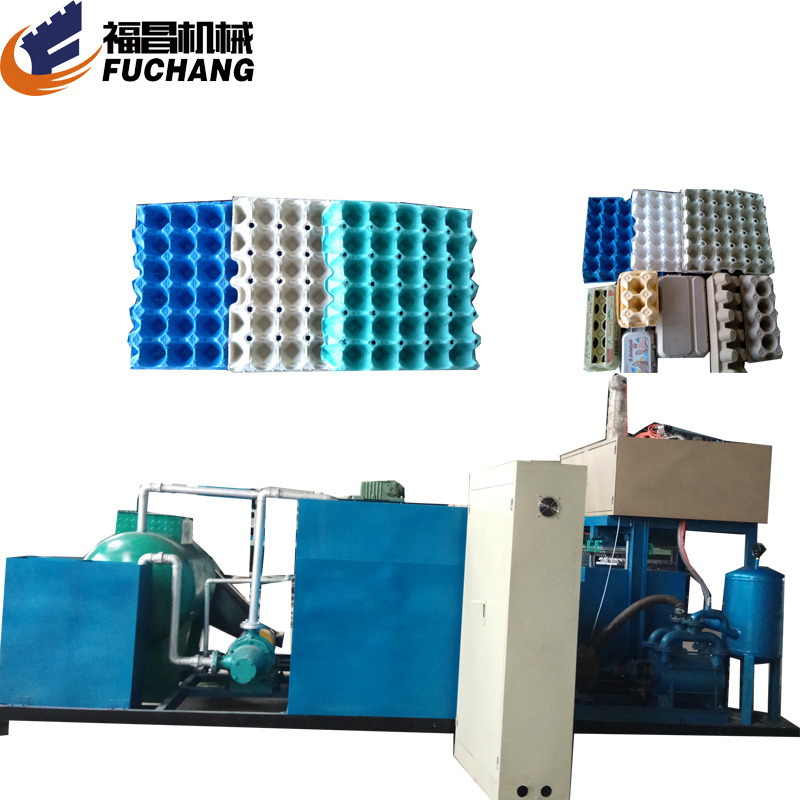

Disposable Paper Pulp Molding Tray Bed Pan Liner Making Machine

Reciprocating type egg tray making production line

is the machine which can use all kinds of waste paper as the raw material to produce egg tray, egg box, pizza box, industrial tray and other packing products etc. by changing different molds. It has received good reputation for its good quality, high output, low energy-consuming and low maintenance.

Our new mini egg tray machine including paper pulp molding system, forming system and connect pipes of all parts. No need installation, easy operated, only need small space, PLC control the pulp absorb time and dehydration time.

1 . Pulping system :

Pulping system is mainly comprised of hydrapulper, pulp pump, multi-function refiner machine, blender, control cabinet, etc.

It can make the pulp by the waste paper. And it is the first step in making process!

2. Forming system :

This part mainly is the egg tray forming machine. We could produce the forming mould and transferring mould based on our customers request. The material of the mould could be Aluminum, Resin, Plastic.

3. Drying line :

This is the very important in the all of line. When the egg tray be made over by the forming machine, the egg tray will be put on the drying line, they will across the drying channel, then you can get the dry tray!

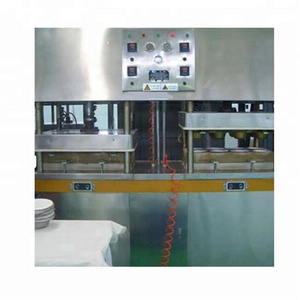

4. Packing machine:

This is the last step, when we get the finished tray from the drying line, we can packing them.

Longkou FuChang Packing Machinery Co., Ltd

is located in Longkou, Shandong. We are the professional manufacturer of packing machinery since 1995 especially in paper pulp molding machine, EPE foam sheet extruder , EPE foam fruit net/ pipe extruder, log splitter wood chipper etc.

Based on so many years abundant experience of producing the paper pulp molding machine and plastic packing machine, we already develop PLC control forming machine, advanced multi-layer drying line, automatic packing system etc. Our factory has a perfect product quality, a high degree of mechanization, technology precision and is trusted by customers. Our machines have exported to many countries, such as Egypt, Ghana, South Africa, Uzbekistan, Thailand, Iceland, India, Venezuela, Vietnam and so on. We keep up the management concept of taking customer's profit into first consideration, helping customers reduce the production cost, improving the quality of the products and offering the best after-sale service.

The people of Fuchang Company promise that we will constantly improve our products and pursue outstanding quality. Top after-sales service is our pledge.

We together with all world friends,

"work shoulder to shoulder ,cooperate sincerely, exchange business opportunities and create glories"

.

We will service for you and solve all the problem for you by 7*24 hours:

1.

We will arrange our professional engineer go to your country to install and test the machine and train your engineers.

2.

Our salesman will be 7*24 hours online for you to solve any problems from your side.

3.

We have been in this line for business for more than 20years.So we have abundant experience of producing machine.

4.

Our machine is high quality. We are your reliable manufacturer of machine.

5.

Contact with us. We can provide you non-stop service with the pre-sale, sale and after sale service. Save your purchasing cost and maintenance costs.

Q1: Will you conduce training for our staff here?

A1:

Yes, we will arrange professional engineers to install and test machine and train the buyer's engineers.

Q2: How about the visiting?

A2:

We are located in Longkou City, Shandong Province, China. The nearest airport is Yantai Airport. You can transfer from Guangzhou, Beijing or Shanghai airport to Yantai airport. We will pick you at the Yantai airport when you come to visit us.

Q3: Could I test machine before placing order?

A3:

We will make the machine running during your visiting to check the working condition. And there are some client who bought our machine in our city. We will take you to their factory to check all working flow.

Q4: How many countries have your machine been installed?

A4:

Our machines have exported many countries such as Korea, Japan, Kazakhstan, Uzbekistan, Malaysia, Russia, Poland, France, Turkey, Thailand, Vietnam, Brazil, Columbia, Argentina, Costa Rica, Algeria, Nigeria, Malawi, Bolivia, Sudan, Jordan, Egypt, South Africa, etc.

Q5: What are your terms of payment?

A5:

We accept T/T, L/C, Western Union and Cash.

Q6: Guaranty period?

A6:

One year guaranty for the machine and 6 months for the electrical appliances.