The motor adopt Siemens standard motor and speed controlled by ABB inverter. The control system adopts Siemens PLC control or button control.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

farcreative

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

38*4*2.5

-

Power (kW):

-

110

-

Weight:

-

2000 KG

-

Name:

-

PE20-110

-

Screw:

-

single screw

-

Motor:

-

SIEMENS Brand

-

Processing Type:

-

Exturding Machine

-

Control:

-

SIEMENS PLC+Touch Screen

-

Extruder:

-

50/38

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

38:1

-

Screw Speed (rpm):

-

40 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

farcreative

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

38*4*2.5

-

Power (kW):

-

110

-

Weight:

-

2000 KG

-

Name:

-

PE20-110

-

Screw:

-

single screw

-

Motor:

-

SIEMENS Brand

-

Processing Type:

-

Exturding Machine

-

Control:

-

SIEMENS PLC+Touch Screen

-

Extruder:

-

50/38

-

Marketing Type:

-

Ordinary Product

Products Description

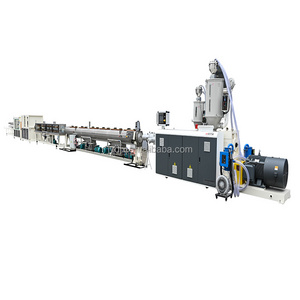

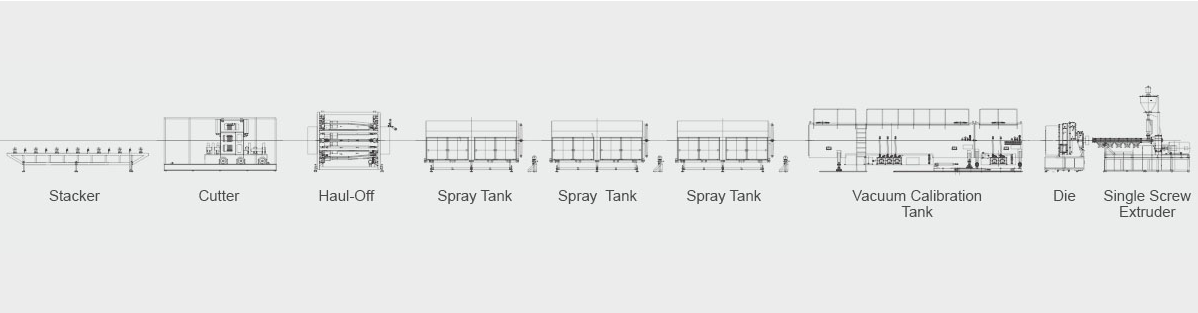

HDPE PIPE Extrusion Production Line

|

1

|

Single Screw Plastic Extruder

|

1set

|

|

2

|

Mould

|

1set

|

|

3

|

Vacuum Calibration Tank

|

1set

|

|

4

|

Hauling Machine

|

1set

|

|

5

|

Pipe Cutting Machine

|

1set

|

|

6

|

Stacker

|

1set

|

1.We are a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines, plastic

production line.

2.Our plastic extrusion lines based on Plastic Extruders: Single Screw Extruder, Conical Twin Screw Extruder and Parallel Twin Screw Extruder

3.Our plastic making machine can make many kinds of plastic productions like: PVC pipe, CPVC pipe, PE/HDPE/PE-RT pipe, PP-R pipe,plastic foamed profile, WPC profile and panel, wood plastic composite and so on.

4.Plastic Extruder is widely used in Plastic industry. It is the main part of Plastic Pipe Extrusion Line, Plastic Profile

Extrusion Line, Plastic Recycling Line and Plastic Granulating Line.

5.We provide plastic machine which can make Agriculture pipe, machines to produce pellet, laminating machine, wooden window frames machine. Our machine can make 3D printer material.

6.Our plastic extruder use good quality screw in plastic machinery. Our plastic machine have long-life.

production line.

2.Our plastic extrusion lines based on Plastic Extruders: Single Screw Extruder, Conical Twin Screw Extruder and Parallel Twin Screw Extruder

3.Our plastic making machine can make many kinds of plastic productions like: PVC pipe, CPVC pipe, PE/HDPE/PE-RT pipe, PP-R pipe,plastic foamed profile, WPC profile and panel, wood plastic composite and so on.

4.Plastic Extruder is widely used in Plastic industry. It is the main part of Plastic Pipe Extrusion Line, Plastic Profile

Extrusion Line, Plastic Recycling Line and Plastic Granulating Line.

5.We provide plastic machine which can make Agriculture pipe, machines to produce pellet, laminating machine, wooden window frames machine. Our machine can make 3D printer material.

6.Our plastic extruder use good quality screw in plastic machinery. Our plastic machine have long-life.

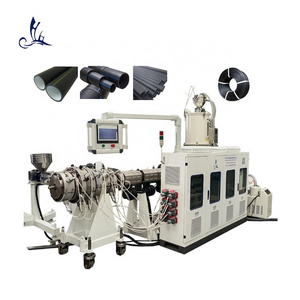

Product Appliaction

It is mainly used for the production of agricultural water supply and drainage, building water supply and drainage, cable

laying,etc. and plastic PVC pipes of various pipe diameters and wall thicknesses. The unit consists of a conical (parallel)

twin-screw extruder, a vacuum setting table, a tractor, a cutting machine, a stacking rack, etc. and all of them are high-quality products.The tractor has two-claw, three-claw, four-claw, six-claw, eight-claw and other traction types.

laying,etc. and plastic PVC pipes of various pipe diameters and wall thicknesses. The unit consists of a conical (parallel)

twin-screw extruder, a vacuum setting table, a tractor, a cutting machine, a stacking rack, etc. and all of them are high-quality products.The tractor has two-claw, three-claw, four-claw, six-claw, eight-claw and other traction types.

Recommend Products

Technical Parameter

|

Specifications

|

|

|

|

|

||||

|

Machine Model

|

|

FCPL

|

|

|

||||

|

Processed Material

|

|

PVC,PE,HDPE PPR and etc.

|

|

|

||||

|

Final Product Shape

|

|

Pipe

|

|

|

||||

|

Output Range(kg/h)

|

|

120-1100

|

|

|

||||

|

Diameter of screw

|

|

50mm-130mm(standard)

|

|

|

||||

|

Voltage Standard

|

|

According to the Voltage of the Customer's Location

|

|

|

||||

|

Warranty

|

|

12 months from the date of bill of lading

|

|

|

||||

|

Technical services

|

|

Project design, factory construction, installation and recommendations, commissioning

|

|

|

||||

|

Diameter scope(mm)

|

Conical twin-screw extruder

|

Motor(KW)

|

Max.Capacity(KG/H)

|

Max. Lineal speed(m/min.)

|

|

20-63

|

SJH50/38

|

55

|

150

|

30

|

|

20-110

|

SJH60/38

|

90

|

350

|

20

|

|

40-160

|

SJH60/38

|

110

|

400

|

15

|

|

75-250

|

SJH75/38

|

132

|

500

|

12

|

|

110-315

|

SJH75/38

|

160

|

600

|

12

|

|

110-450

|

SJH90/38

|

250

|

850

|

8

|

|

315-630

|

SJH90/38

|

280

|

1050

|

4

|

|

500-800

|

SJH120/38

|

355

|

1300

|

2

|

|

700-1200

|

SJH75/38

SJH90/38

|

160/250

|

1450

|

1

|

|

1000-1600

|

SJH120/38

SJH90/38

|

355/280

|

1900

|

0.6

|

Details Images

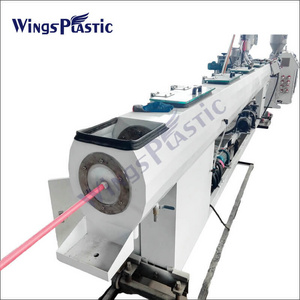

1.Far Creative Single Screw Extruder

The extruder of HDPE pipe line adopt high efficiency screw & barrel, notched feeding cylinder and is equipped with strong water jacket cooler, which greatly improves its transmission capacity and guarantees high-efficiency extrusion. the gearbox is hardening teeth gearbox with self-lubrication system.

2.Die Mould

- Spacious flow channel design to guarantee highextrusion capacity and good melt.

- Optimized temperature control and flow channeldesign, precise melt temperature control.

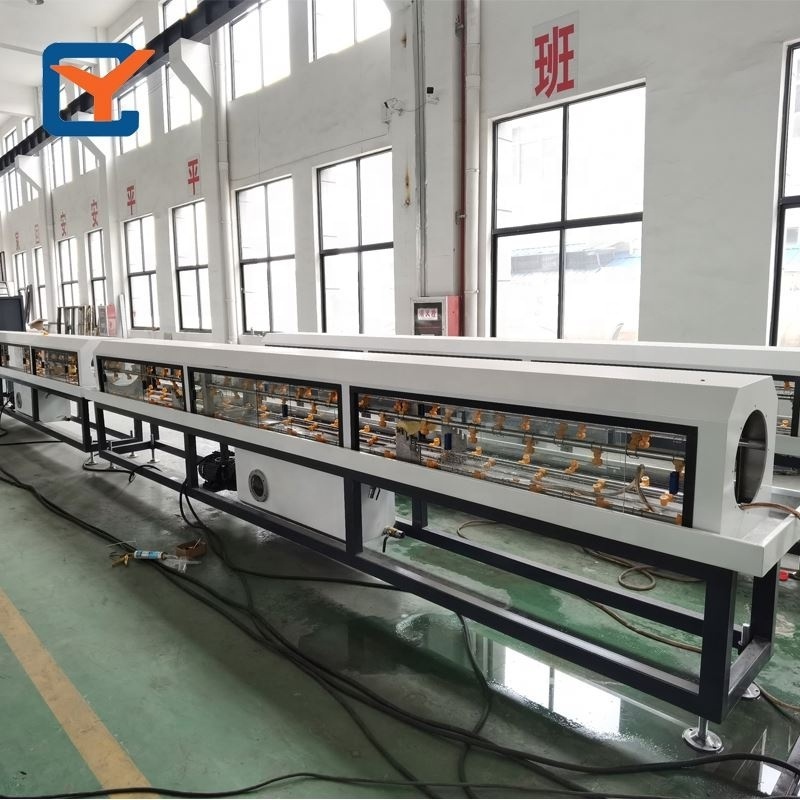

3. Vacuum

calibration

tank

The tank body of vacuum calibration tank adopt two chamber structure the vacuum calibration and cooling parts. Both of vacuum tank and spraying cooling tank adopt stainless steel 304.

The excellent vacuum system ensures the precise sizing for pipes;spraying

cooling will improve the cooling efficiency; Auto water temperature control system make the machine more intelligent.

4.

Haul-off Unit

For the different pipe size and different speed requirement, Far Creative developed kinds of haul-off unit accordingly.

For the large diameterpipe, a pipe winch device is equipped to the production line to reduced the waster material.

5.

Cutter

Hot Searches