- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

NANSEN

-

Model Number:

-

NS-Aluminium spout

-

Size:

-

D20~43mm

-

Tolerance:

-

±0.5

-

Surface treatment:

-

White washed,polishing

-

Application:

-

aluminum kettle, tea pot

-

Production process:

-

stretching, bending, punching,forming

-

MOQ:

-

1000pcs

-

Packing:

-

carton

-

Certificate:

-

CO,ISO etc

-

LOGO Printing:

-

Available

Quick Details

-

Design Style:

-

American Style

-

Material:

-

Metal

-

Feature:

-

Sustainable, Stocked

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

NANSEN

-

Model Number:

-

NS-Aluminium spout

-

Size:

-

D20~43mm

-

Tolerance:

-

±0.5

-

Surface treatment:

-

White washed,polishing

-

Application:

-

aluminum kettle, tea pot

-

Production process:

-

stretching, bending, punching,forming

-

MOQ:

-

1000pcs

-

Packing:

-

carton

-

Certificate:

-

CO,ISO etc

-

LOGO Printing:

-

Available

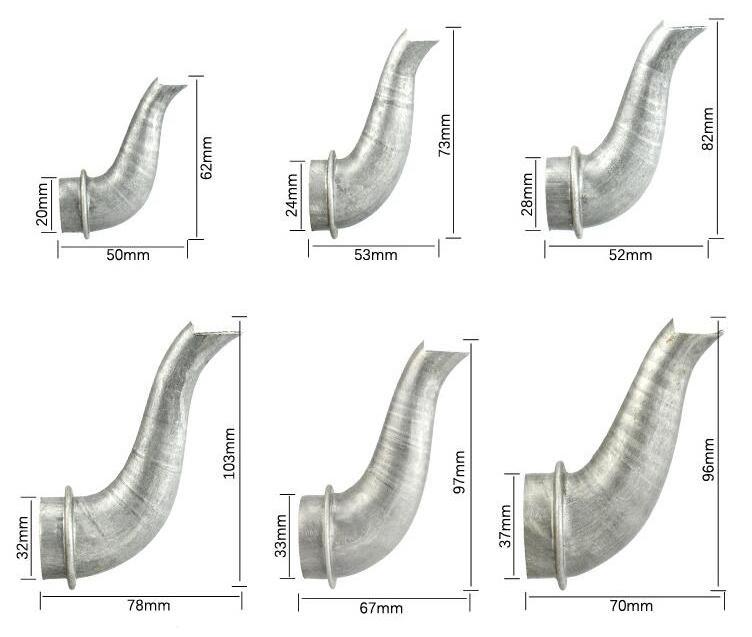

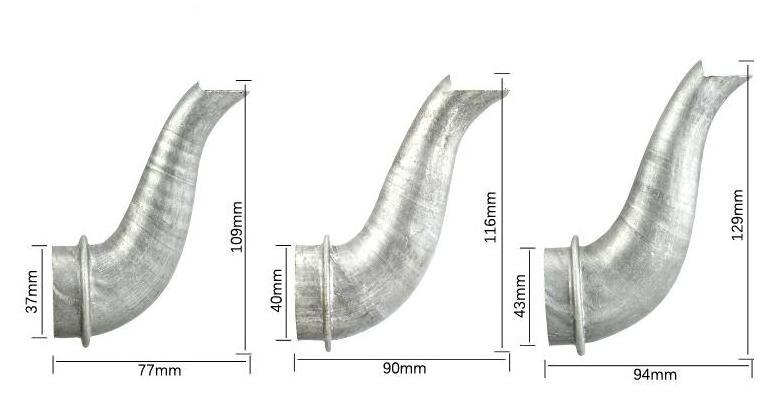

Shining Aluminium Mouth Polishing Tea Kettle Mouth Aluminium Spout 22-24cm

| Product Name | Aluminum kettle spout |

| Type | Water kettles |

| Material | Aluminum alloy, pure aluminum |

| Color | silver |

| Size | D20mm/24mm/28mm/32mm/33mm/37mm/40mm/43mm |

| Tolerance | ±0.5 |

| Surface treatment |

Blank,White washed, Polishing,

caustic wash |

| Application | aluminum kettle, tea pot, whistling tea kettle, jug |

| Production process | blanking, stretching, contracting, bending, rising,punching,cutting,pressing,forming |

| MOQ | 1000pcs |

| Packing | Bulk packing, high-quality export carton |

| Certificate | CO,ISO etc |

| LOGO Printing | Available |

Molded aluminum kettle spout , for various diameters. used for aluminum kettle ,tea pot,whistling tea kettle and jug.can be customized.

1. Aluminum circle cutting( raw materials )

Aluminum circle diameter and thickness are determined according to the size equirements of your product, purchase from suppliers directly.

2. Oiled

Apply a thin layer of stretch oil to the surface of the aluminum circle, remove the aluminum scrap and burrs left on the aluminum disc when cut circle, so that reduce

breakage in the next stretching process.

3. Deep Drawing

The oil-coated aluminum circle is stretched into a straight tube through five steps.

4. Saw Tube Mouth

The stretched tubular mouth is sawed flat, and prepared for the next sharpening process.

5. Tubular oiling

Because the sharpening in the next step is equivalent to stretching, after the mouth is sawed flat, you need to apply oil again, and remove the aluminum scrap and burrs

to reduce the damage during the sharpening.

6. Tip

A sawed straight tube,through 3 times tipping process, the diameter of the straight tube remains unchanged, the bottom diameter becomes smaller and the depth becomes larger.

7. Annealing

Through 5 times stretching and 3 times tipping, high temperature is generated in this process, which makes the product material hard, and is not conducive to the next

process production. Therefore it must be annealed to soften the material, increase the material's elongation performance, reduce bending, and water swelling damaged.

8. Bending

Bending the annealed product, filled into the water swelling mold to forming.

9. Water Swelling Forming

Put the bent product into the water swelling mold, and the high-pressure water is rapidly pressurized inside the product, so that the product material is extended to

combine with the model, and the two mold separated, until the product has the shape of a spout.

10. Saw Spout

Saw the formed spout water outlet out.

11. Blank holder

The product water inlet is blank pressing forming.

Ms. Monica

Shanghai Nansen Industry Co., Ltd.

Address: Pudong District, Shanghai, China.

Tel: 86-21-2024 9001

Wechat /what'app : 0086-182 0211 2981

Email: sales at nansencn. com